Method for removing sulfide from oil product by using choline chloride/oxalic acid type eutectic solvent by virtue of oxidation-extraction integrated process

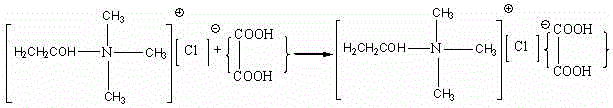

A technology of deep eutectic solvent and choline chloride, which is applied in the fields of refining with oxygenated compounds, petroleum industry, refining hydrocarbon oil, etc., can solve the limitation of large-scale industrial application and development, complex synthesis process of ionic liquid, difficulty in purification, etc. problems, to achieve the effect of reducing production costs, simplifying desulfurization procedures, and enhancing environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

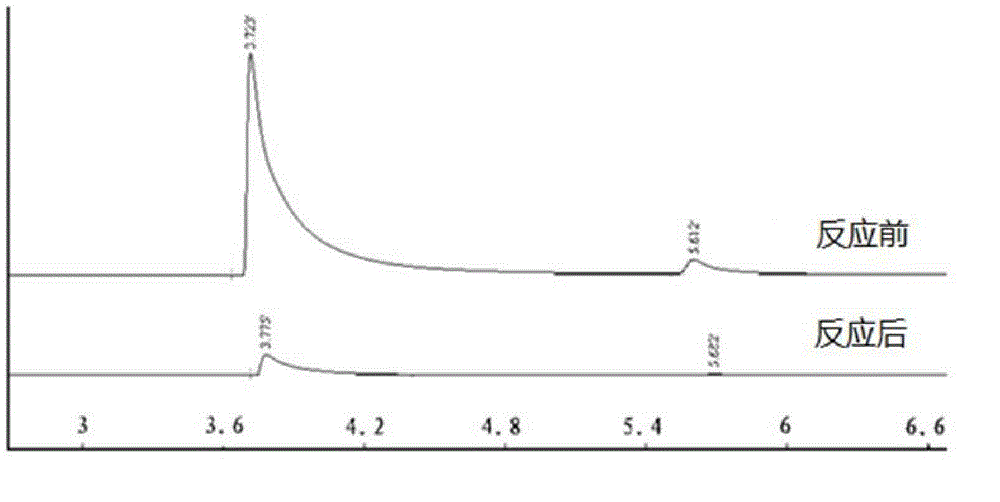

[0026] A certain amount of dibenzothiophene (DBT) was weighed and dissolved in n-octane to prepare a simulated oil with a sulfur content of 500ppm. Weigh 10 mL of simulated oil and 8 mL of choline chloride / oxalic acid deep eutectic solvent into a 50 mL Erlenmeyer flask, add 0.1 mL of H 2 o 2 . After stirring at 40°C for 180 min, the mixture was cooled to room temperature, separated into layers in a separatory funnel, and the sample in the upper oil phase was drawn, and the sulfur content was measured with a WK-2D microcoulomb comprehensive analyzer and the desulfurization rate was calculated to be 84 %.

Embodiment 2

[0028] A certain amount of dibenzothiophene (DBT) was weighed and dissolved in n-octane to prepare a simulated oil with a sulfur content of 500ppm. Weigh 10 mL of simulated oil and 8 mL of choline chloride / oxalic acid deep eutectic solvent into a 50 mL Erlenmeyer flask, add 0.2 mL of H 2 o 2 . After stirring at 40°C for 180 min, the mixture was cooled to room temperature, separated into layers in a separatory funnel, and the sample in the upper oil phase was drawn, and the sulfur content was measured with a WK-2D microcoulomb comprehensive analyzer and the desulfurization rate was calculated to be 92 %.

Embodiment 3

[0030] A certain amount of dibenzothiophene (DBT) was weighed and dissolved in n-octane to prepare a simulated oil with a sulfur content of 500ppm. Weigh 10 mL of simulated oil and 8 mL of choline chloride / oxalic acid deep eutectic solvent into a 50 mL Erlenmeyer flask, add 0.3 mL of H 2 o 2 . After stirring at 40°C for 180 min, the mixture was cooled to room temperature, separated into layers in a separatory funnel, and the sample in the upper oil phase was drawn, and the sulfur content was measured with a WK-2D microcoulomb comprehensive analyzer and the desulfurization rate was calculated to be 93 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com