Preparation and application of graphene-based cadmium sulfide composite

A technology of alkenyl cadmium sulfide and composite materials, applied in the direction of material electrochemical variables, etc., can solve the problems of agglomeration growth, easy migration of nano-catalyst particles, loss of catalytic activity, etc., to prevent powder agglomeration deactivation, electron transport ability Enhanced, easily controlled effects of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

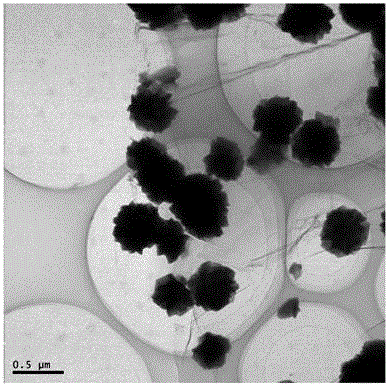

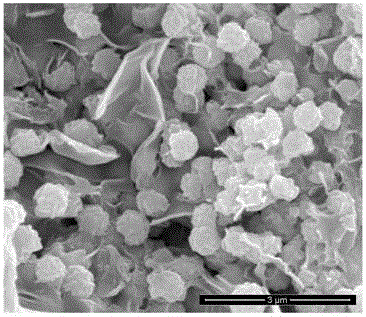

Image

Examples

Embodiment 1

[0028] 1) Weigh 10 mg of ground graphite oxide and disperse it in 50 mL of ultrapure water for ultrasonic treatment for 2 h, let it stand for 4 hours, take the clear brown liquid in the upper layer, that is, graphene oxide (GO) solution for use; weigh 0.1142 g of CdCl 2 2.5H 2 Dissolve O in 75mL ultrapure water, stir magnetically for 15min to dissolve completely, and pass nitrogen gas during this process;

[0029] 2) Take 15 mL of graphene oxide (GO) solution and add CdCl 2 Continue to stir in the aqueous solution for 15min to make Cd 2+ Fully adsorbed on the surface of graphene oxide; add 0.1241g of Na 2 S 2 o 3 ·5H 2 O continued to stir for 15min to make S 2 o 3 2- With the Cd adsorbed on the GO surface in advance 2+ Adsorption occurs; put the reaction solution into a hydrothermal reaction kettle, and put it in an oven at a constant temperature of 160°C for about 8 hours;

[0030] 3) The reacted hydrothermal kettle was naturally cooled overnight, and the hydrotherm...

Embodiment 2

[0032] 1) Weigh 0.1142g CdCl 2 2.5H 2 O was dissolved in an appropriate amount of ultrapure water and magnetically stirred for 15 minutes to completely dissolve, and nitrogen gas was introduced during this process;

[0033] 2) Add 0.1241g Na 2 S 2 o 3 ·5H 2 O continued to stir for 15min to make S 2 o 3 2- with Cd 2+ Adsorption occurs; put the reaction solution into a hydrothermal reaction kettle, and put it in an oven at a constant temperature of 160°C for 10 hours;

[0034] 3) The reacted hydrothermal kettle was naturally cooled overnight, and the sample was taken out, washed three times with ultrapure water, and dried to obtain CdS crystals.

Embodiment 3

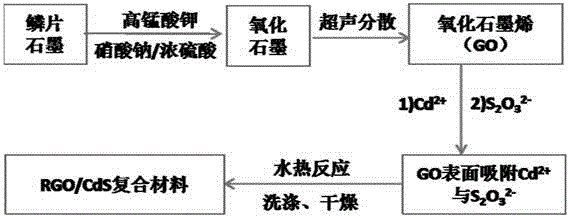

[0036] like figure 1 shown, including the following steps:

[0037]1) Mix 0.5g of sodium nitrate and 34mL~44mL of concentrated sulfuric acid in a beaker, put them in an ice-water bath and stir, add 1g of 325 mesh flake graphite and continue to stir for 30 minutes to fully react, so that the graphite layer is fully oxidized, and carboxyl, hydroxyl and bridge oxygen group; then add 5g of potassium permanganate, the process of adding should be slow, continue to react for 30min, and then react at a constant temperature of 35°C for 2h; add 50mL of ultrapure water and keep stirring; move the beaker into a preheated to 98°C In an oil bath reactor, react for 15 minutes, add 4mL of 30% hydrogen peroxide dropwise to the reaction solution; wash with dilute hydrochloric acid, filter the product, and wash repeatedly with deionized water until neutral; filter the final product with suction , dry, and the dried product is solid graphite oxide, which is ground into a powder with an agate mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com