Multi-edge MoS2 nano piece/graphene composite nanomaterial and preparation method thereof

A composite nanomaterial and graphene composite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

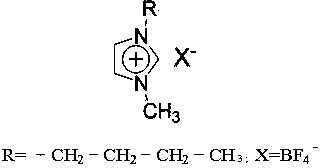

[0025] 1) Ultrasonic disperse 2.5 mmol graphene oxide in 60 mL deionized water, then add 0.4 mL ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate (see figure 1 Schematic diagram), and stir well;

[0026] 2) Then add 0.76 g (6.25 mmol) L-cysteine and 0.3 g (1.25 mmol) sodium molybdate (Na 2 MoO 4 2H 2 O), and keep stirring to completely dissolve L-cysteine and sodium molybdate, and adjust the volume to about 80 mL with deionized water;

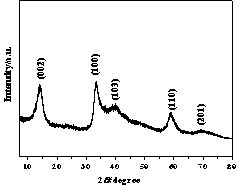

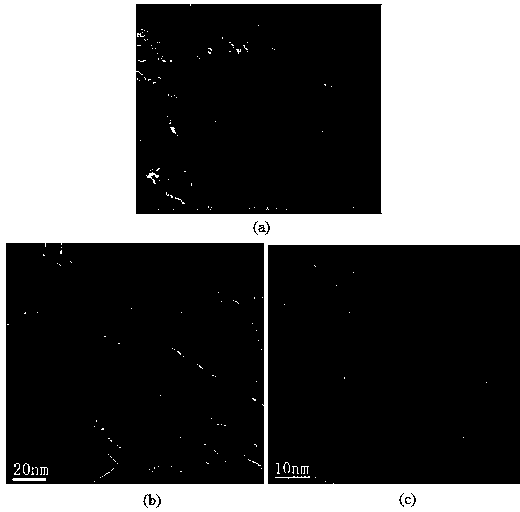

[0027] 3) Transfer the obtained mixture to a 100 mL hydrothermal reaction kettle, seal the reaction kettle and place it in a constant temperature oven. After hydrothermal reaction at 240 °C for 24 h, let it cool down to room temperature naturally, and separate it by centrifugation. Collect the solid product, wash it thoroughly with deionized water, and dry it under vacuum at 100 °C. The obtained hydrothermal solid product is heat-treated at 500 °C for 2 h in a nitrogen / hydrogen mixed atmosphere, and the volume fraction of hydrog...

Embodiment 2

[0035] 1) Ultrasonically disperse 3.75 mmol of graphene oxide in 60 mL of deionized water, and then add 0.8 mL of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate (see figure 1 Schematic diagram), and stir well;

[0036] 2) Then add 0.76 g (6.25 mmol) L-cysteine and 0.3 g (1.25 mmol) sodium molybdate (Na 2 MoO 4 2H 2 O), and keep stirring to completely dissolve L-cysteine and sodium molybdate, and adjust the volume to about 80 mL with deionized water;

[0037] 3) Transfer the obtained mixture to a 100 mL hydrothermal reaction kettle, seal the reaction kettle and place it in a constant temperature oven. After hydrothermal reaction at 240 °C for 24 h, let it cool down to room temperature naturally, and separate it by centrifugation. Collect the solid product, wash it thoroughly with deionized water, and dry it under vacuum at 100 °C. The obtained hydrothermal solid product is heat-treated at 500 °C for 2 h in a nitrogen / hydrogen mixed atmosphere, and the volume ...

Embodiment 3

[0040] 1) Ultrasonic disperse 2.5 mmol graphene oxide in 60 mL deionized water, then add 1.0 mL ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate, and stir thoroughly;

[0041] 2) Then add 12.5 mmol of L-cysteine and 2.5 mmol of sodium molybdate (Na 2 MoO 4 2H 2 O), and keep stirring to completely dissolve L-cysteine and sodium molybdate, and adjust the volume to about 80 mL with deionized water;

[0042] 3) Transfer the obtained mixture to a 100 mL hydrothermal reaction kettle, seal the reaction kettle and place it in a constant temperature oven. After hydrothermal reaction at 240 °C for 24 h, let it cool down to room temperature naturally, and separate it by centrifugation. Collect the solid product, wash it thoroughly with deionized water, and dry it under vacuum at 100 °C. The obtained hydrothermal solid product is heat-treated at 500 °C for 2 h in a nitrogen / hydrogen mixed atmosphere, and the volume fraction of hydrogen in the mixed gas is 10% , to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com