mo 0.5 w 0.5 s 2 Nanotile and graphene composite nanomaterial and preparation method

A composite nanomaterial, graphene composite technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of strong hydrophobicity and strong mutual electrostatic interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

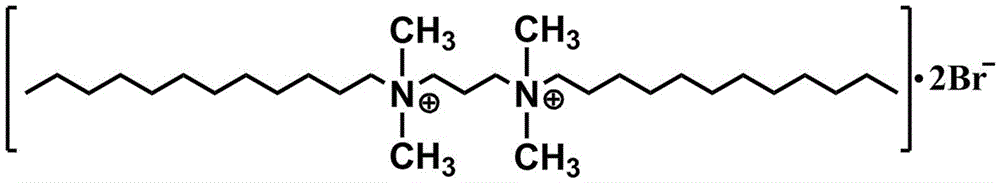

[0023] 1) Ultrasonically disperse 2.5 mmol of graphene oxide in 60 mL of deionized water, then add 0.8 mmol of gemini surfactant N-dodecylpropylenediamine diammonium bromide, and stir thoroughly;

[0024] 2) Then add 0.76g (6.25 mmol) L-cysteine, 0.625 mmol ammonium thiomolybdate and 0.625 mmol ammonium thiotungstate in sequence, and keep stirring to make L-cysteine, ammonium thiomolybdate Dissolve completely with ammonium thiotungstate, and adjust the volume to about 80 mL with deionized water;

[0025] 3) Transfer the obtained mixed solution to a 100 mL hydrothermal reaction kettle, put the reaction kettle into a constant temperature oven, and after hydrothermal reaction at 230 °C for 24 h, let it cool down to room temperature naturally, and collect the solid by centrifugation The product was washed thoroughly with deionized water and dried under vacuum at 100°C;

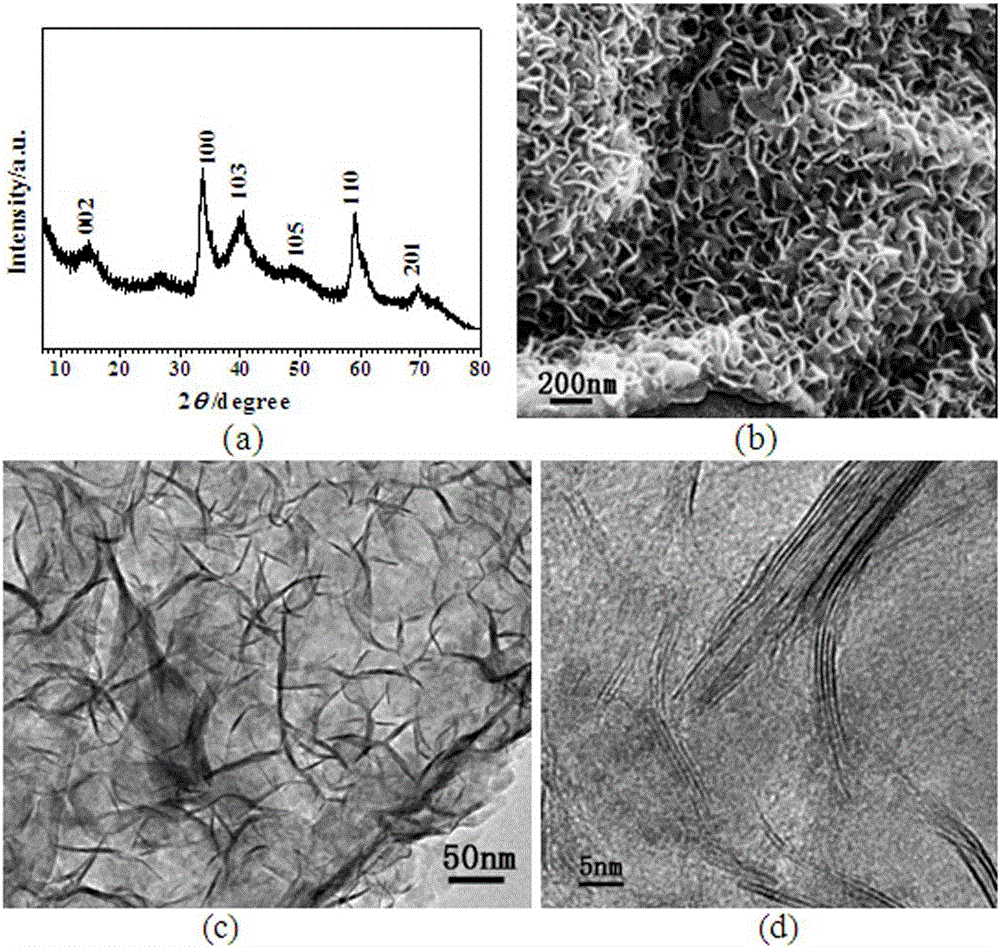

[0026] 4) The solid product obtained above was heat-treated at 800 °C for 2 h in a nitrogen / hydrogen mixed atm...

Embodiment 2

[0034] 1) Ultrasonically disperse 2.5 mmol of graphene oxide in 60 mL of deionized water, then add 0.8 mmol of gemini surfactant N-dodecylpropylenediamine diammonium bromide, and stir thoroughly;

[0035] 2) Then add 1.50g (12.5 mmol) L-cysteine, 1.25 mmol ammonium thiomolybdate and 1.25 mmol ammonium thiotungstate in sequence, and keep stirring to make L-cysteine, ammonium thiomolybdate Dissolve completely with ammonium thiotungstate, and adjust the volume to about 80 mL with deionized water;

[0036] 3) Transfer the obtained mixture to a 100 mL hydrothermal reaction kettle, put the reaction kettle into a constant temperature oven, and after hydrothermal reaction at 220 °C for 24 h, let it cool down to room temperature naturally, and collect the solid by centrifugation The product was washed thoroughly with deionized water and dried under vacuum at 100°C;

[0037] 4) The solid product obtained above was heat-treated at 800 °C for 2 h in a nitrogen / hydrogen mixed atmosphere t...

Embodiment 3

[0040] 1) Ultrasonically disperse 3.75 mmol of graphene oxide in 60 mL of deionized water, then add 1.2 mmol of gemini surfactant N-dodecylpropylenediamine diammonium bromide, and stir thoroughly;

[0041] 2) Then add 0.76g (6.25 mmol) L-cysteine, 0.625 mmol ammonium thiomolybdate and 0.625 mmol ammonium thiotungstate in sequence, and keep stirring to make L-cysteine, ammonium thiomolybdate Dissolve completely with ammonium thiotungstate, and adjust the volume to about 80 mL with deionized water;

[0042] 3) Transfer the obtained mixed solution to a 100 mL hydrothermal reaction kettle, and add deionized water to adjust the volume to 80 mL, put the reaction kettle in a constant temperature oven, and conduct a hydrothermal reaction at 240 °C for 24 h, let It was naturally cooled to room temperature, and the solid product was collected by centrifugation, washed thoroughly with deionized water, and dried under vacuum at 100°C;

[0043] 4) The solid product obtained above was heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com