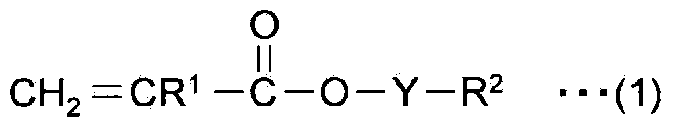

Fluorine-containing copolymer, method for producing same, and water repellent/oil repellent agent composition

A technology of water and oil repellent, copolymer, applied in chemical instruments and methods, textiles and papermaking, other chemical processes, etc., can solve the problem of high environmental load, achieve low environmental load, sufficient water and oil repellency, good washing The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0177] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to the following description. Examples 1, 2, 7-11 are examples, and examples 3-6, 12-15 are comparative examples.

[0178] [Raw materials, etc.]

[0179] The raw materials etc. used in this Example are as follows.

[0180] (monomer)

[0181] C6FA: 2-perfluorohexylethyl acrylate (a product synthesized by a known method using 2-perfluorohexylethanol as a raw material).

[0182] C6FMA: 2-perfluorohexylethyl methacrylate (a product synthesized by a known method using 2-perfluorohexylethanol as a raw material).

[0183] MMA: methyl methacrylate (manufactured by Tokyo Chemical Industry Co., Ltd., a product obtained by simple distillation and purification).

[0184] DEAEMA: diethylaminoethyl methacrylate (manufactured by Tokyo Chemical Industry Co., Ltd.).

[0185] nBMA: n-butyl methacrylate (Tg: 20° C., manufactured by Tokyo Kasei Kogyo Co., Ltd., product obtained by sim...

example 1

[0230] Step (I): Synthesis of Macromonomer Precursor

[0231] In a three-necked flask of 300 mL, add C6FA (109 g, 261 mmol), 2-mercaptoethanol (1 g, 12.3 mmol) as a chain transfer agent, AIBN (0.2 g, 1.3 mmol) as a polymerization initiator and AK-225 as a solvent (110g, 533mmol), install a serpentine condenser with a circulating cooler and stirring blades, slowly heat up to 60°C under a nitrogen atmosphere, and stir. After 18 hours (after stirring overnight), it was cooled at room temperature to obtain a polymerization crude liquid. The obtained crude liquid was added dropwise to about 20 times the mass of cooled methanol, and stirred to precipitate a macromonomer precursor. The obtained macromonomer was filtered and vacuum-dried overnight at 50° C. to obtain a macromonomer precursor (1) having a C6FA-derived unit. The degree of polymerization of the resulting macromonomer precursor (1) is determined by 1 Obtained by H-NMR.

[0232] Step (II): Synthesis of macromonomer (a)...

example 2~6

[0239] Fluorinated copolymers (2) to (6) were synthesized in the same manner as in Example 1, except that the composition ratios of the components used in the synthesis in the step (I) and the step (III) were changed as shown in Table 2. Moreover, the water and oil repellent compositions (2)-(6) containing the fluorinated copolymers (2)-(6) were produced similarly to Example 1, respectively.

[0240] Table 3 shows the evaluation results of water and oil repellency and washing durability in Examples 1 to 6.

[0241] [Table 2]

[0242]

[0243] [table 3]

[0244]

[0245] As shown in Table 3, the water and oil repellent compositions (1), (2) comprising a fluorine-containing copolymer having a unit (A), a unit (B) and a unit (C) as a unit containing a unit X were used. In Examples 1 and 2, sufficient water and oil repellency was obtained, and the decrease in water and oil repellency after washing was also suppressed, and good washing durability was obtained.

[0246] On ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com