Culture method of sulfur synergy denitrification simultaneous nitrogen and phosphorous removal granular sludge

A simultaneous denitrification, dephosphorization, and granular sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, anaerobic digestion, etc., can solve problems such as insufficient phosphorus removal and reduction of excess sludge, and achieve The effect of shortening the processing time, good settling performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

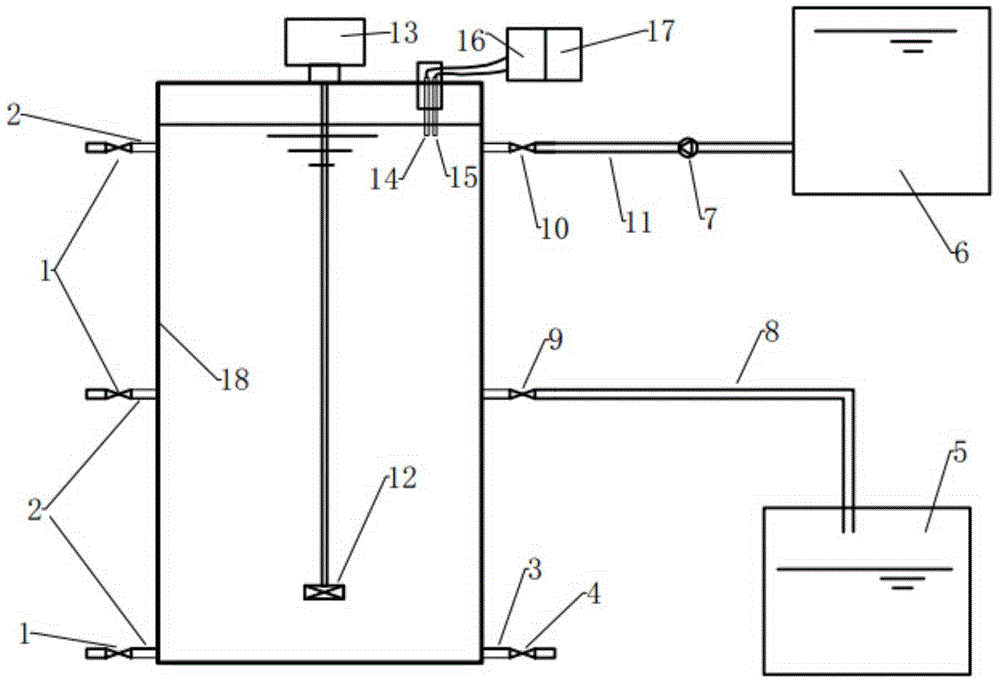

[0045] Example 1 Cultivation of sulfur synergistic denitrification synchronous denitrification and phosphorus removal granular sludge

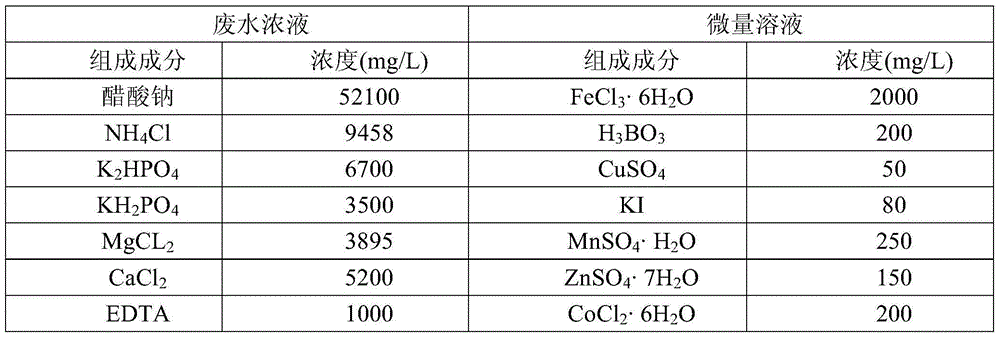

[0046] ①Add 10L of mud-water mixture of anaerobic activated sludge (collected from Hong Kong Sha Tin Sewage Treatment Plant) with an initial sludge concentration of 5.98g SS / L to a batch-type activated sludge reactor (reaction volume 10L), and settle to remove the upper After clear liquid 5L, enter 5L synthetic waste water (its component content is shown in Table 1) and carry out sludge domestication, improve its microbial activity simultaneously with the environment that domesticated microorganisms adapt to the presence of phosphate; Described synthetic waste water contains carbon source, sulfur source As well as the phosphorus source, the carbon source is provided by sodium acetate; the initial concentration of acetate in the synthetic wastewater is 150mg C / L; the sulfur source is provided by sodium sulfate, and the initial concentration of s...

Embodiment 2

[0049] (1) Sludge domestication stage: add the sulfur synergistic denitrification, denitrification and phosphorus removal inoculation sludge prepared in Example 1 to the batch activated sludge reactor (SBR, reaction volume 1.4L), wherein the inoculation sludge concentration It is 9.45g SS / L, and the dosage is 1.4L. After adding it into the reactor, it precipitates to remove 0.7L of the supernatant, and then feeds 0.7L of water into the reactor containing carbon source, sulfur source, phosphorus source, calcium The synthetic wastewater of ions and magnesium ions begins the anaerobic phosphorus release stage, the carbon source is provided by sodium acetate, the sulfur source is provided by sodium sulfate, and the phosphorus source is provided by dipotassium hydrogen phosphate and potassium dihydrogen phosphate, which are The initial concentration in the waste water is respectively 150mgC / L, 200mgS / L, 20mgP / L, and described calcium ion, magnesium ion are provided by calcium chlori...

Embodiment 3

[0058] (1) Sludge domestication stage: add the sulfur synergistic denitrification denitrification and dephosphorization seeding sludge prepared in Example 1 to the reactor, the sludge concentration is 9.00mg SS / L, and the synthetic wastewater (Table 1) is used as Enter water, start the reactor to start the anaerobic phosphorus release stage; when the carbon source concentration drops to zero, add potassium nitrate 20mg N / L (final concentration in the reactor) as a nitrogen source, and the reactor enters the anoxic phosphorus uptake stage; The operating conditions are: stirring speed 150rpm, temperature 20-25°C, influent pH=7, hydraulic retention time 16h; when the average particle size of sludge particles is 50μm, the removal rate of acetate reaches 100%, and the removal rate of nitrate up to 90%, the removal rate of phosphate reaches 30%, SVI 5 50mL / g, SVI 30 30mL / g, the domestication stage is over;

[0059] (2) Granular sludge growth stage: After the domestication stage, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com