Chemosynthesis preparation method for methyl catechol

A technology of guaiacol and chemical synthesis, applied in ether preparation, organic chemistry, ester reaction to prepare ether, etc., can solve the problems of product quality decline, increased chance of veratrole, product loss, etc., and reduce the chance of generating tar , good controllability and selectivity, and the effect of offsetting the cost of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

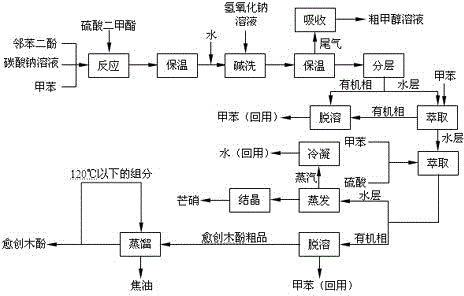

Image

Examples

Embodiment 1

[0033] Embodiment 1, the present invention is mainly made of the raw material of following preferred parts by weight:

[0034] A) Catechol Industrial grade >99.5% 500kg;

[0035] B) Dimethyl sulfate Industrial grade >99.5% 480 kg;

[0036] C) Sodium carbonate Industrial grade ≥99% 460kg;

[0037] D) Toluene Industrial grade 99.9% 105 kg;

[0038] E) Sodium hydroxide Industrial grade 99% 110 kg.

[0039] F) sulfuric acid industrial grade 60% 60kg

[0040] The chemical synthesis process of guaiacol of the present invention comprises the following production steps:

[0041] (1) Reaction process

[0042]Add 85kg of toluene and 460kg of sodium carbonate solution to the reaction kettle at room temperature, add 500kg of catechol while stirring, turn on steam heating after feeding, control the temperature at about 95°C for 0.5h, and simultaneously add 480kg of dimethyl sulfate The ester is poured into the head tank for later use. After the end of t...

Embodiment 2

[0049] Embodiment 2: A kind of chemical synthesis formula of guaiacol mainly contains the following raw materials to make:

[0050] A) Catechol Industrial grade >99.5% 450kg;

[0051] B) Dimethyl sulfate Industrial grade >99.5% 450 kg;

[0052] C) Sodium carbonate industrial grade ≥99% 420kg;

[0053] D) Toluene Industrial grade 99.9% 95 kg;

[0054] E) Sodium hydroxide Industrial grade 99% 100 kg.

[0055] F) sulfuric acid industrial grade 60% 50kg

[0056] The chemical synthesis process of guaiacol of the present invention comprises the following production steps:

[0057] (1) Reaction process

[0058] Add 75kg of toluene and 420kg of sodium carbonate solution to the reaction kettle at room temperature, add 450kg of catechol while stirring, turn on steam heating after feeding, control the temperature at about 95°C for 0.5h, and simultaneously add 450kg of dimethyl sulfate The ester is poured into the head tank for later use. After the end...

Embodiment 3

[0065] Embodiment 3: A kind of chemical synthesis formula of guaiacol mainly contains the following raw materials to make:

[0066] A) Catechol Industrial grade >99.5% 550kg;

[0067] B) Dimethyl sulfate Industrial grade >99.5% 500 kg;

[0068] C) Sodium carbonate Industrial grade ≥99% 480kg;

[0069] D) Toluene Industrial grade 99.9% 115 kg;

[0070] E) Sodium hydroxide Industrial grade 99% 120 kg.

[0071] F) sulfuric acid industrial grade 60% 100kg

[0072] The chemical synthesis process of guaiacol of the present invention comprises the following production steps:

[0073] (1) Reaction process

[0074] Add 95kg of toluene and 480kg of sodium carbonate solution to the reaction kettle at room temperature, add 550kg of catechol while stirring, turn on steam heating after feeding, control the temperature at about 95°C for 0.5h, and simultaneously add 500kg of dimethyl sulfate The ester is poured into the head tank for later use. After the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com