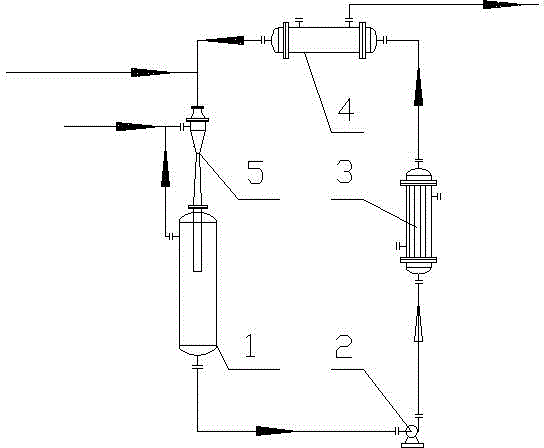

Device and method for production of o-chloroaniline through continuous catalytic hydrogenation reduction of o-nitro chloro benzene

A technology of o-nitrochlorobenzene and o-chloroaniline, which is applied in the field of o-chloroaniline continuous catalytic hydrogenation reduction to produce o-chloroaniline, can solve the problem of large consumption of catalysts and dechlorination inhibitors, and inconvenient catalyst regeneration and replacement. Convenience, poor catalyst selectivity and other problems, to achieve good heat transfer effect, uniform hydrogenation reaction, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Put ortho-nitrochlorobenzene, platinum-carbon (Pt / C) catalyst with a mass percentage of 1% platinum, and diethylamine dechlorination inhibitor into the hydrogenation reactor to lay out the primer, and use nitrogen to purify the system. The air is replaced cleanly, and then the nitrogen is replaced with hydrogen; then the feed valve is opened, and o-nitrochlorobenzene and dechlorination inhibitors are continuously sent into the hydrogenation reactor, wherein o-nitrochlorobenzene, noble metal catalyst, dechlorination The mass ratio of the inhibitor is 1:0.001:0.001, hydrogen gas is introduced to carry out the hydrogenation reduction reaction, the hydrogenation reaction temperature is 60°C, and the pressure is 0.5MPa; the hydrogenation liquid mixed with the catalyst in the hydrogenation reactor enters first through the circulation pump The heat exchanger removes the heat of reaction to maintain the reaction temperature of the system, and then passes through the c...

Embodiment 2

[0023] Example 2: Put o-nitrochlorobenzene, platinum-carbon (Pt / C) catalyst with 3% mass percentage of platinum, and triethanolamine dechlorination inhibitor into the hydrogenation reactor to arrange the bottom material, and nitrogen in the system The air is replaced cleanly, and then the nitrogen is replaced with hydrogen; then the feed valve is opened, and o-nitrochlorobenzene and dechlorination inhibitor are continuously sent into the hydrogenation reactor, wherein o-nitrochlorobenzene, noble metal catalyst, dechlorination inhibitor The mass ratio of the catalyst is 1:0.003:0.003, and hydrogen gas is introduced to carry out the hydrogenation reduction reaction. The hydrogenation reaction temperature is 80°C and the pressure is 1.0MPa; The heater removes the heat of reaction to maintain the reaction temperature of the system, and then through the cross-flow filter, the catalyst and part of the hydrogenated liquid enter the injector together with fresh o-nitrochlorobenzene and...

Embodiment 3

[0024] Example 3: Put o-nitrochlorobenzene, platinum-carbon (Pt / C) catalyst with 5% mass percentage of platinum, and pyridine dechlorination inhibitor into the hydrogenation reactor to arrange the primer, and use nitrogen to purify the air in the system. The replacement is clean, and then the nitrogen is replaced with hydrogen; then the feed valve is opened, and the o-nitrochlorobenzene and the dechlorination inhibitor are continuously sent into the hydrogenation reactor, wherein the o-nitrochlorobenzene, the noble metal catalyst, the dechlorination inhibitor The mass ratio of the hydrogenation reactor is 1:0.005:0.005, and hydrogen is introduced to carry out the hydrogenation reduction reaction. The hydrogenation reaction temperature is 100°C and the pressure is 1.5MPa; the hydrogenation liquid mixed with the catalyst in the hydrogenation reactor first enters the heat exchange through the circulating pump The device removes the reaction heat to maintain the reaction temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com