Imidazoline type neutralization corrosion inhibitor and preparation method thereof

An imidazoline-type and imidazoline technology is applied in the field of preparation of imidazoline-type neutralizing corrosion inhibitors, which can solve the problems of inability to inhibit corrosion under salt scale, poor dispersibility of corrosion inhibitors, etc. High efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

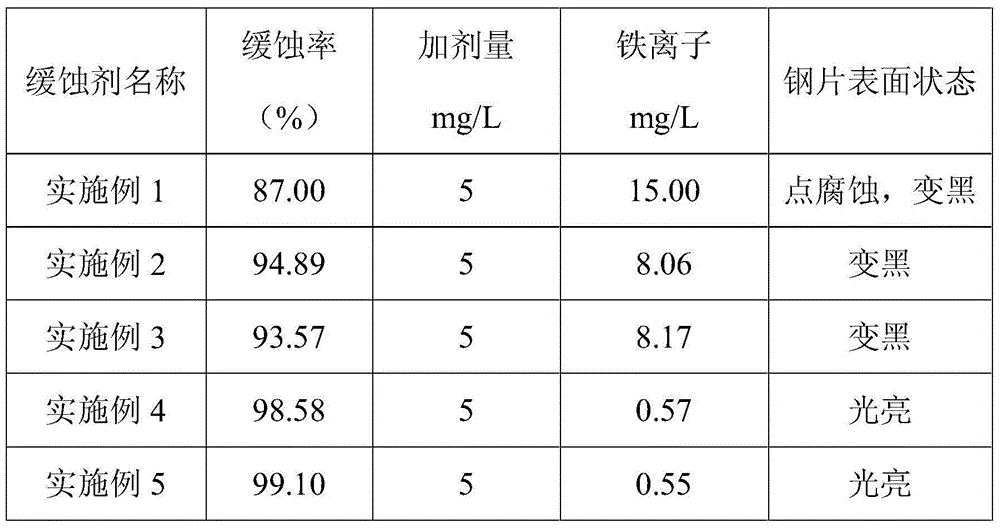

Examples

Embodiment 1

[0028] An imidazoline type neutralizing corrosion inhibitor, which is composed of the following components in parts by weight:

[0029] 15 parts of imidazoline derivatives and long-chain organic amine mixture, and the mass ratio of imidazoline derivatives and long-chain organic amines is 3:1;

[0030] 10 parts of a mixture of 20% ammonia water and methylamine in any proportion

[0031] Polyethylene glycol 2 parts

[0032] 35 parts of methanol

[0033] Weigh the main corrosion inhibitor, neutralizer and dispersant according to the measured parts, put them into the measured parts of the solvent, and stir evenly to obtain the imidazoline type neutralized corrosion inhibitor.

Embodiment 2

[0035] An imidazoline type neutralizing corrosion inhibitor, which is composed of the following components in parts by weight:

[0036] 40 parts of imidazoline derivatives and long-chain organic amine mixture, and the mass ratio of imidazoline derivatives and long-chain organic amines is 5:1;

[0037] Concentration is 20% mixture of ammonia water and dimethylamine 20 parts

[0038] Lignosulfonate 5 parts

[0039] Ethylene glycol 73 parts

[0040] Weigh the main corrosion inhibitor, neutralizing agent and dispersant according to the measured parts, and put them directly into the measured parts of the solvent, and stir evenly to obtain the imidazoline type neutralized corrosion inhibitor.

Embodiment 3

[0042] An imidazoline type neutralizing corrosion inhibitor, which is composed of the following components in parts by weight:

[0043] 30 parts of imidazoline derivatives and long-chain organic amine mixture, and the mass ratio of imidazoline derivatives and long-chain organic amines is 4:1;

[0044] Concentration is 20% ammonia water and ethylamine mixture 15 parts

[0045] 3 parts petroleum sulfonate

[0046] Propylene glycol 50 parts

[0047] Weigh the main corrosion inhibitor, neutralizing agent and dispersant according to the measured parts, and put them directly into the measured parts of the solvent, and stir evenly to obtain the imidazoline type neutralized corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com