Yield increase method of BTX aromatic hydrocarbons

A technology of BTX aromatics and aromatics, applied in the field of increasing production of BTX aromatics, can solve the problem of low utilization value of non-aromatics, and achieve self-sufficiency in reaction heat, good technical effects, and optimal adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

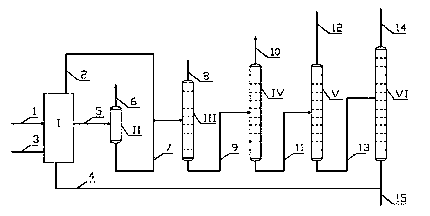

Embodiment 1

[0023] with C 6 + As the raw material (the content of benzene is 24.4 tons / hour, the content of toluene is 9.3 tons / hour, the content of xylene is 2.1 tons / hour, and the content of ethylbenzene is 3.6 tons / hour), using figure 1 The process technology increases the production of BTX, and the circulation amount of the reaction liquid phase product is 30% by weight. Reaction unit, the reactor is a single-stage fixed-bed adiabatic reactor, the reaction pressure is 2.75 MPa, the reaction temperature is 360°C, the hydrogen partial pressure is 1.4 MPa, and the liquid phase weight space velocity is 2.1h -1 ; The stripper is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the temperature of the partial condenser at the top of the tower is 40°C, and the non-condensable gas is discharged, wherein the molar concentration of ethane is 44.1%, and the molar concentration of propane is 36.9% %, other light hydrocarbons 19.0mol%. The benzene tower adop...

Embodiment 2

[0027] to reform C 9 +as raw material (benzene content is 0.03 tons / hour, toluene content is 39.5 tons / hour, xylene content is 33.9 tons / hour, C 9 + Aromatics content is 524.5 tons / hour), using figure 1 The process technology increases the production of BTX, and the circulation amount of the reaction liquid phase product is 30% by weight. Reaction unit, reaction pressure 2.8 MPa, reaction temperature 320°C, hydrogen partial pressure 1.14 MPa; stripping column is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the control temperature of the top separator is 40°C, discharge Non-condensable gas, in which the molar concentration of ethane is 20.3%, the molar concentration of propane is 66.3%, and other light hydrocarbons are 13.4mol%. The benzene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 59.7 tons / hour of benzene product with a purity of 99.95wt% is obtained at the top of the tow...

Embodiment 3

[0031] to reform C 9 + as raw material (benzene content is 0.1 tons / hour, toluene content is 40 tons / hour, xylene content is 33.9 tons / hour, C 9 + Aromatics content is 524.5 tons / hour), using figure 1 The process technology increases the production of BTX, and the circulation amount of the reaction liquid phase product is 50% by weight. Reaction unit, reaction pressure 2.8 MPa, reaction temperature 320°C, hydrogen partial pressure 1.14 MPa; stripping column is a 44-layer float valve tray, the operating pressure at the top of the tower is 0.7MPa, the control temperature of the top separator is 40°C, discharge Non-condensable gas, in which the molar concentration of ethane is 20.3%, the molar concentration of propane is 66.3%, and other light hydrocarbons are 13.4mol%. The benzene tower adopts 55 layers of valve trays, the operating pressure at the top of the tower is 0.05MPa, and 59.7 tons / hour of benzene product with a purity of 99.95wt% is obtained at the top of the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com