Grounding body based on nano-conductive corrosion resistant coating

An anti-corrosion coating, nano-conducting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] 1. Preparation of steel grounding body:

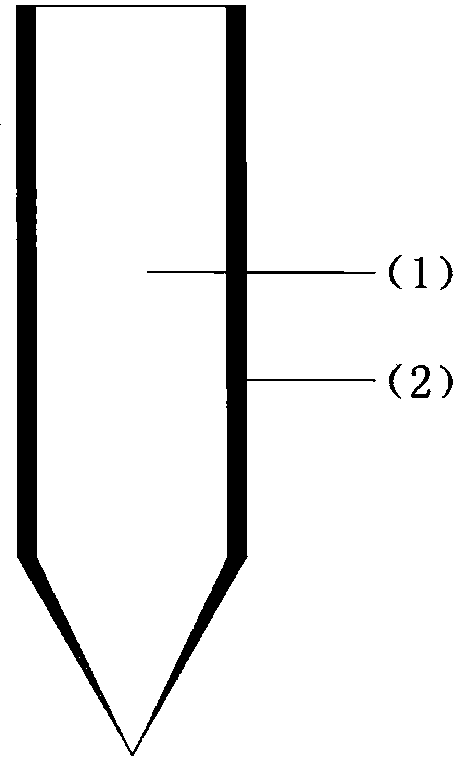

[0020] The first step is to customize a batch of steel grounding rods with a diameter of 2-3 cm and a length of 200-250 cm. figure 1 shown;

[0021] The second step is to prepare a graphene layer (2) on the above steel rod (1) by chemical vapor deposition;

[0022] In the third step, a graphene layer (2) is prepared on the surface of the steel grounding body by chemical vapor deposition. The carbon source used can be methane, ethylene, acetylene and other gases, and the auxiliary reaction gases are hydrogen and argon, wherein the hydrogen plays a reducing role, and the argon plays a protective role. The basic process is as follows: hydrogen and argon are introduced into the reaction, hydrogen is used to reduce and remove oxides on the metal surface, and argon plays a protective role. When the temperature rises to the first stage (600-1100°C), keep it warm for a period of time, and then feed carbon sources such as methane, eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com