Cetirizine hydrochloride soft capsule and preparation method thereof

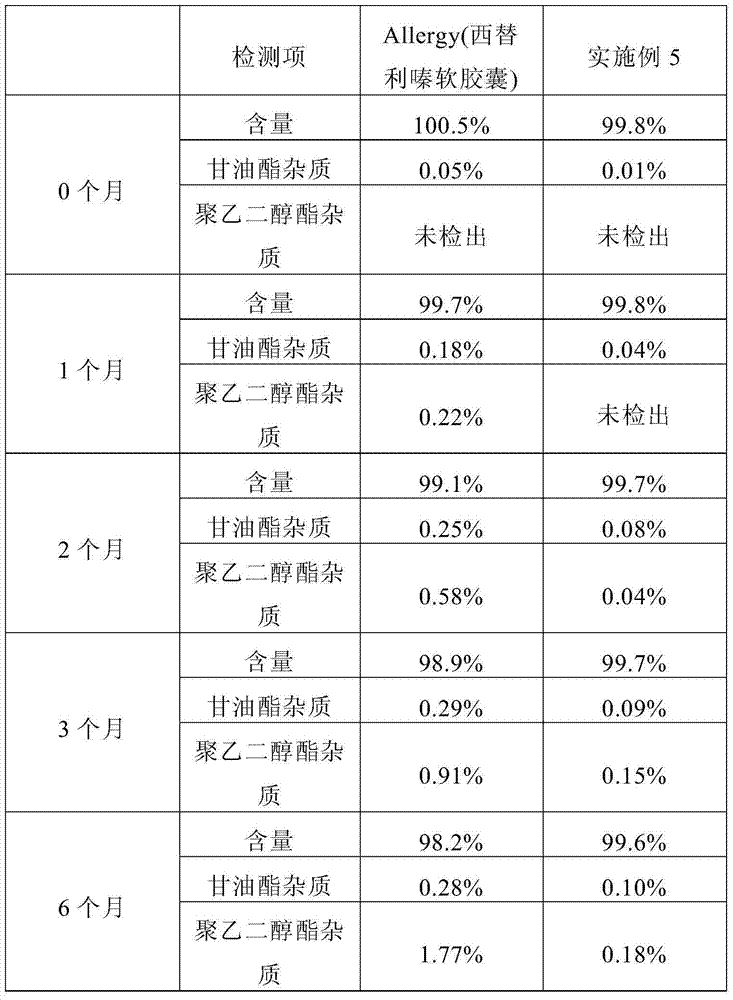

A technology of cetirizine hydrochloride and soft capsules, which is applied in the field of cetirizine hydrochloride soft capsules and its preparation, can solve the problems of dosage influence, unstable content, short validity period, etc., and improve stability and validity period , reduce potential adverse reactions, facilitate transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Prescription composition

[0049] Content composition: cetirizine hydrochloride 10g, water 150g, dipotassium hydrogen phosphate 35g, potassium dihydrogen phosphate 15g, polyethylene glycol 400640g,

[0050] Capsule shell composition: gelatin 1000g, glycerin 400g, sorbitol 50g, water 700g.

[0051] 2) Preparation method

[0052] a. Preparation of contents: Dissolve potassium dihydrogen phosphate in water, then add cetirizine hydrochloride to the obtained potassium dihydrogen phosphate solution, stir to dissolve, add polyethylene glycol 400, stir well, and degas , nitrogen protection.

[0053] b. Preparation of gelatin solution: mix glycerin, sorbitol, and water, heat to 70°C, add gelatin, stir the solution, degas, and keep warm at 60°C for later use.

[0054] c. Compress the contents and gelatin solution into soft capsules on a soft capsule machine, dry, polish, and pack.

Embodiment 2

[0056] 1) Prescription composition

[0057] Content composition: 10g of cetirizine hydrochloride, 50g of water, 10g of dipotassium hydrogen phosphate, 400-230g of polyethylene glycol,

[0058] Capsule shell composition: gelatin 1000g, glycerin 300g, sorbitol 125g, water 850g.

[0059] 2) Preparation method

[0060] a. Preparation of contents: Dissolve dipotassium hydrogen phosphate in water, then add cetirizine hydrochloride to the obtained dipotassium hydrogen phosphate solution, stir to dissolve, add polyethylene glycol 400, stir well, and degas , nitrogen protection.

[0061] b. Preparation of gelatin solution: Glycerin, sorbitol, and water were mixed and heated to 70° C., then gelatin was added to the obtained mixed solution, stirred, degassed, and kept at 60° C. for later use.

[0062] c. Compress the contents and gelatin solution into soft capsules on a soft capsule machine, dry, polish, and pack.

Embodiment 3

[0064] 1) Prescription composition

[0065] Content composition: cetirizine hydrochloride 10g, water 180g, dipotassium hydrogen phosphate 30g, potassium dihydrogen phosphate 18g, polyethylene glycol 400862g,

[0066] Capsule shell composition: gelatin 1000g, glycerin 200g, sorbitol 200g, water 1000g.

[0067] 2) Preparation method

[0068] a. Preparation of contents: Dissolve dipotassium hydrogen phosphate and potassium dihydrogen phosphate in water, then add cetirizine hydrochloride to the obtained solution, stir to dissolve, add polyethylene glycol 400, stir evenly, and degas , nitrogen protection.

[0069] b. Preparation of gelatin solution: Mix glycerin, sorbitol and water and heat to 70°C, add gelatin, stir the solution, degas, keep warm at 60°C for later use.

[0070] c. Compress the contents and gelatin solution into soft capsules on a soft capsule machine, dry, polish, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com