Metal-ceramic composite product and preparation method thereof

A metal-ceramic composite and metal composite material technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of weak bonding force between metal decoration and ceramic matrix, easy metal wear, and easy occurrence of pores and holes. The method is simple and easy to implement, the cost is low, and the product yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing a metal-ceramic composite product, the steps of which include:

[0020] S1, filling A material in the groove of the ceramic substrate with pattern grooves on the surface, and then sintering at 1000°C-1200°C in a protective atmosphere to form a reinforced phase skeleton in the groove, wherein A is selected from W, Mo, Ni, Cr, stainless steel, WC, TiC, SiC, ZrC or ZrO 2 one or more of them. Generally the filler material particles, preferably, the particle size of the particles is 0.1-100 μm. Filling the A material can be done by a common filling method. Preferably, in the present invention, the A material is dissolved in a solvent to form a slurry, and the slurry is filled in the groove. The function and type of the organic solvent are well known to those skilled in the art. . The slurry can also contain modified additives such as powder surfactants. For example, silane coupling agent 9116 is added to the slurr...

Embodiment 1

[0029] (1) Weigh 300g of W powder (particle size D50 is 1μm) and 1.2g of silane coupling agent 9116, dissolve in 25g of methyl silicone oil, stir the two for about 2h and mix them evenly, defoaming in a vacuum drying box for 30min, to obtain W-containing slurry, coat the W-containing slurry on the surface grooves of the zirconia ceramics with a depth of 0.20mm and a width of 0.5mm formed during the preforming of the green body, fill the grooves, and place them in a vacuum drying oven again. The zirconia ceramics were degassed for 30min, then the zirconia ceramics were sintered in a vacuum resistance furnace, heated to 600℃ at 2℃ / min, kept at 600℃ for 1h, then heated to 1100℃ at 10℃ / min and kept for 1h to form a reinforced The porosity of the reinforced phase skeleton was measured to be 62.8% by the drainage method.

[0030] (2) Put the zirconium-aluminum-copper-nickel alloy above the surface groove of the zirconia ceramic prepared above and put it into the infiltration furnace...

Embodiment 2-4

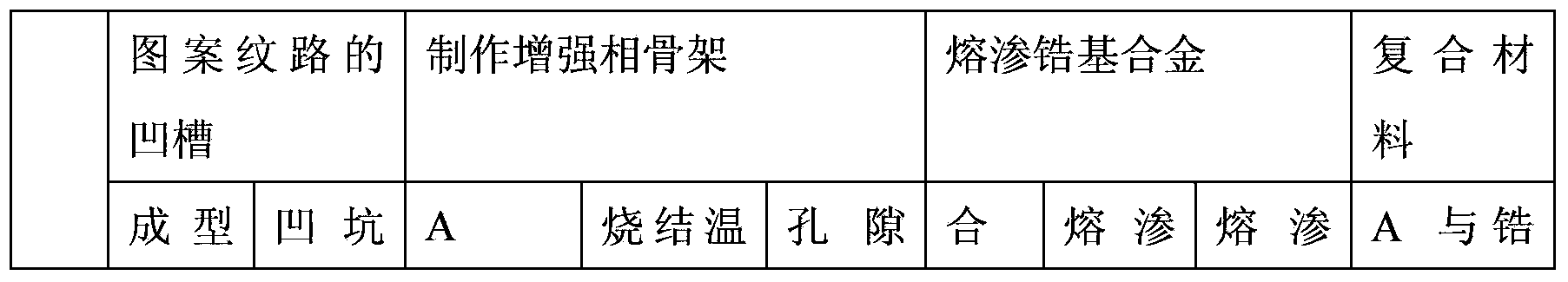

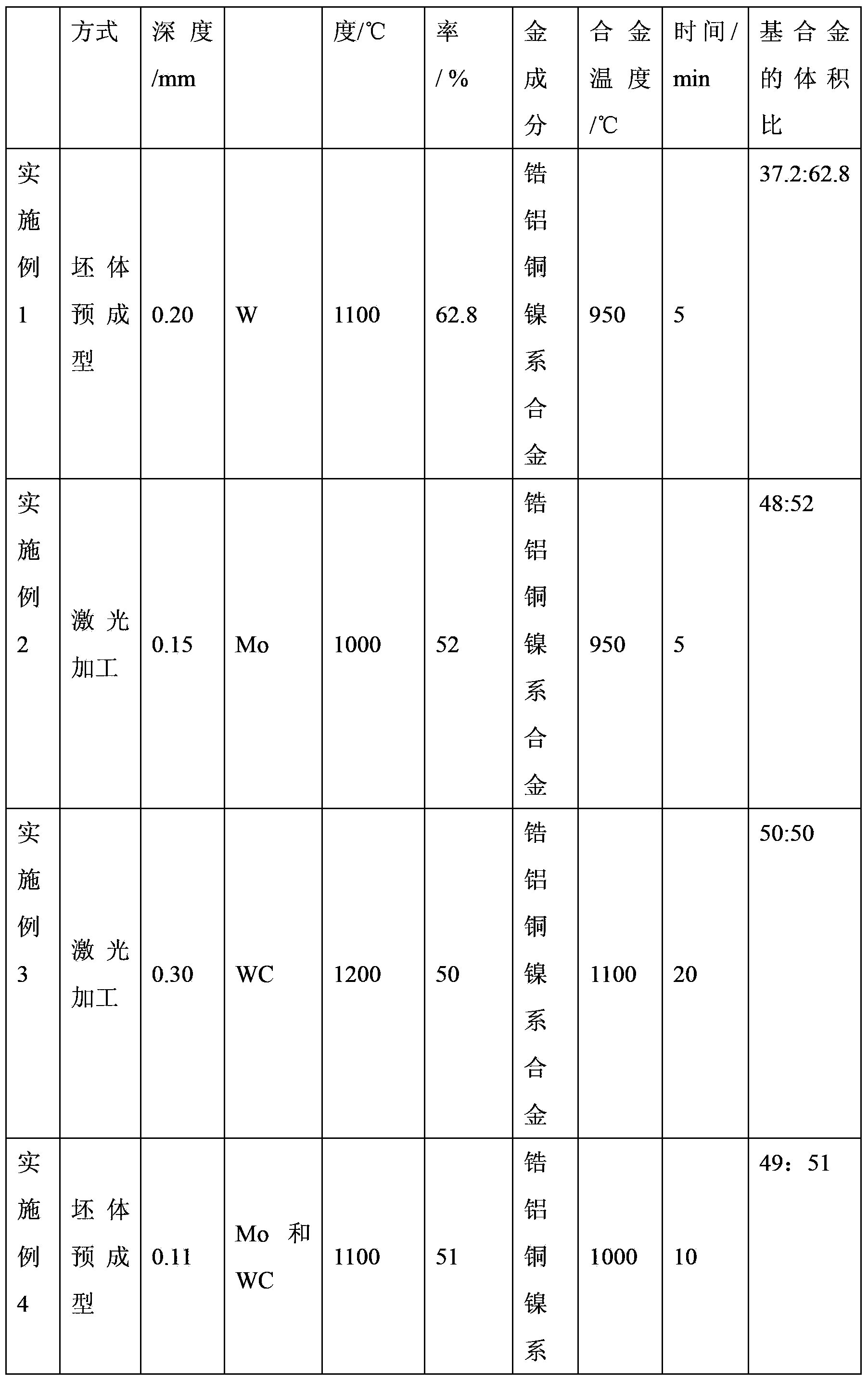

[0032] The metal-ceramic composite product samples S2-S7 were prepared by the same method as in Example 1, and the different specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com