Surface modification treatment method of halloysite nanotube

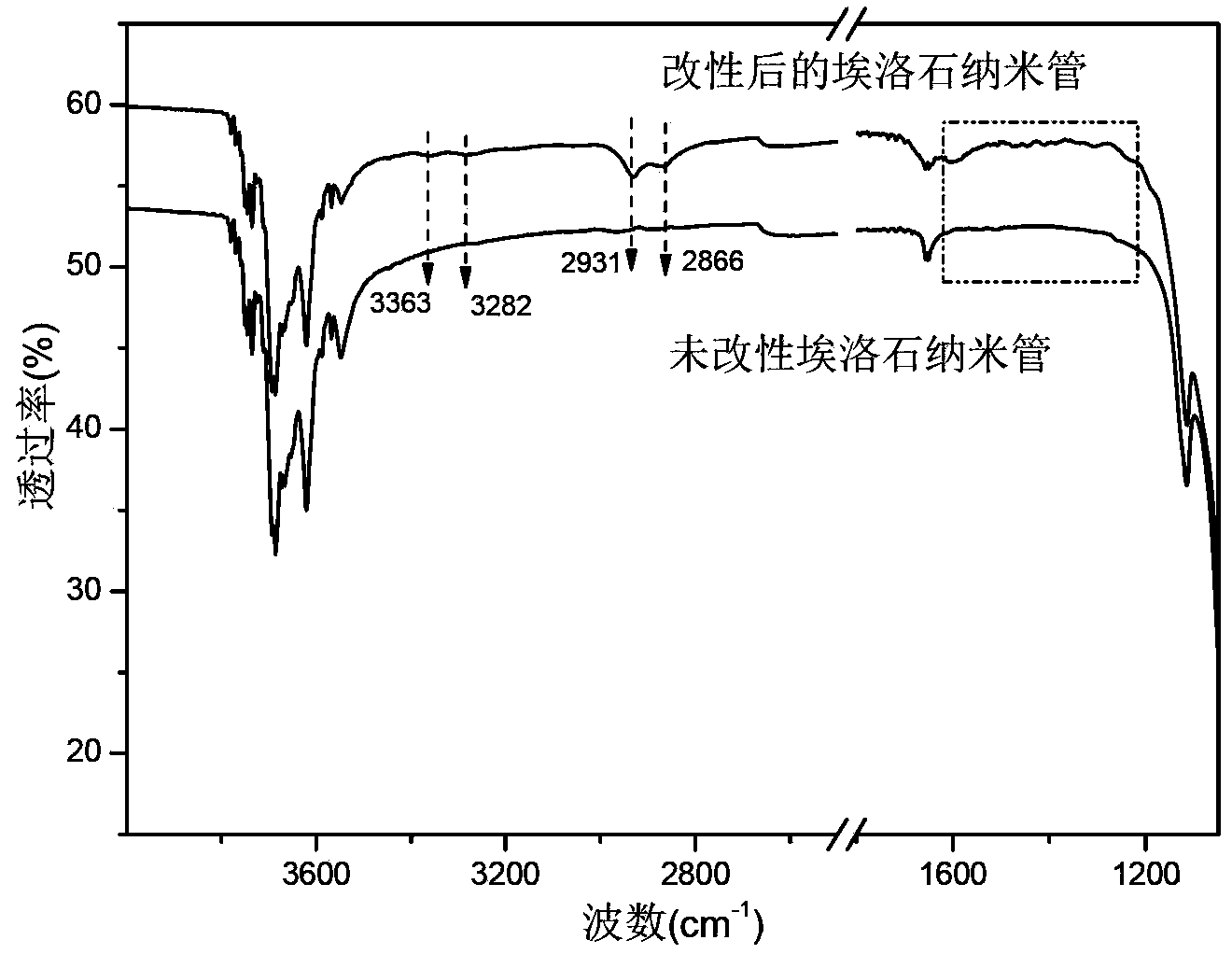

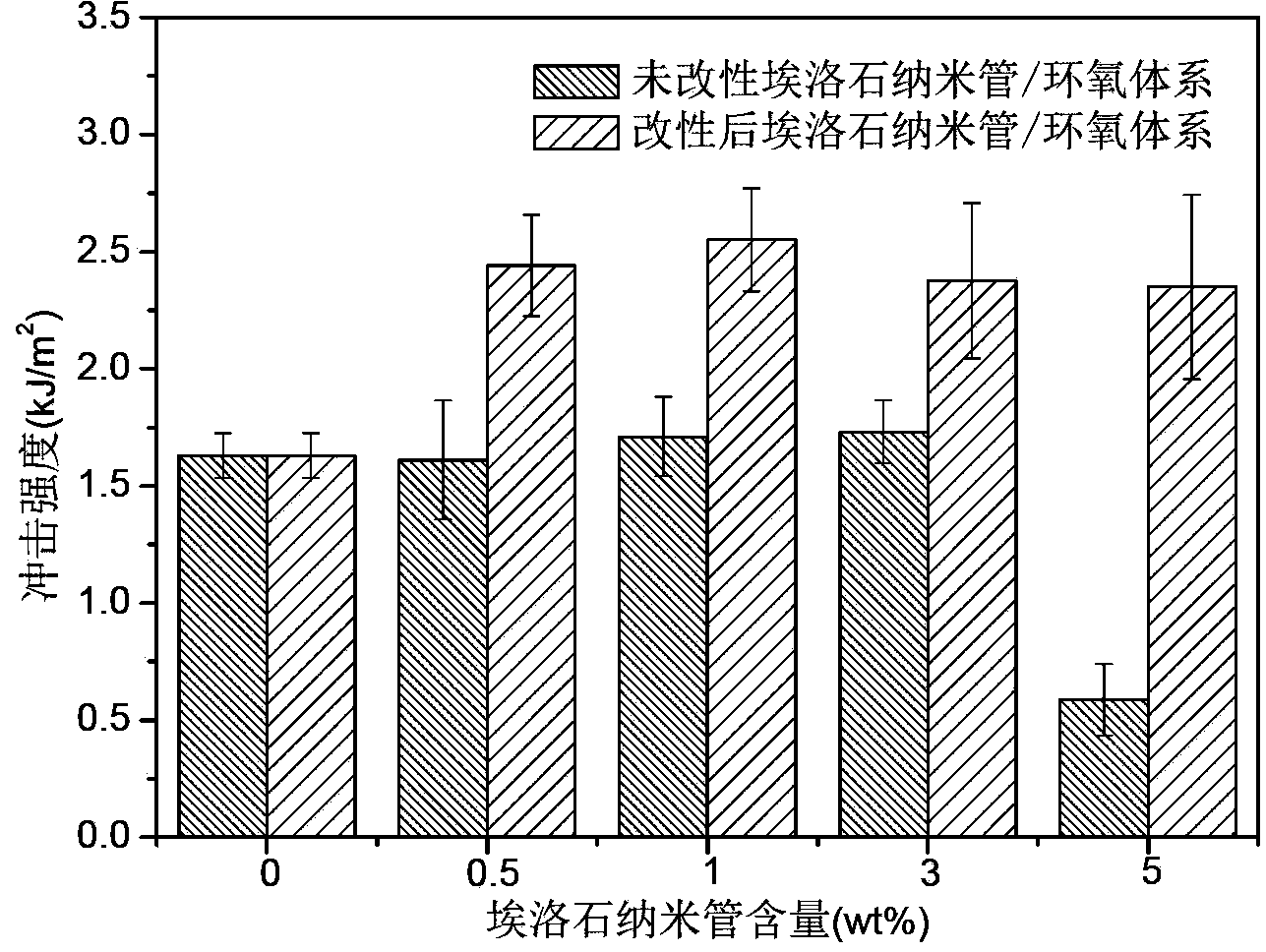

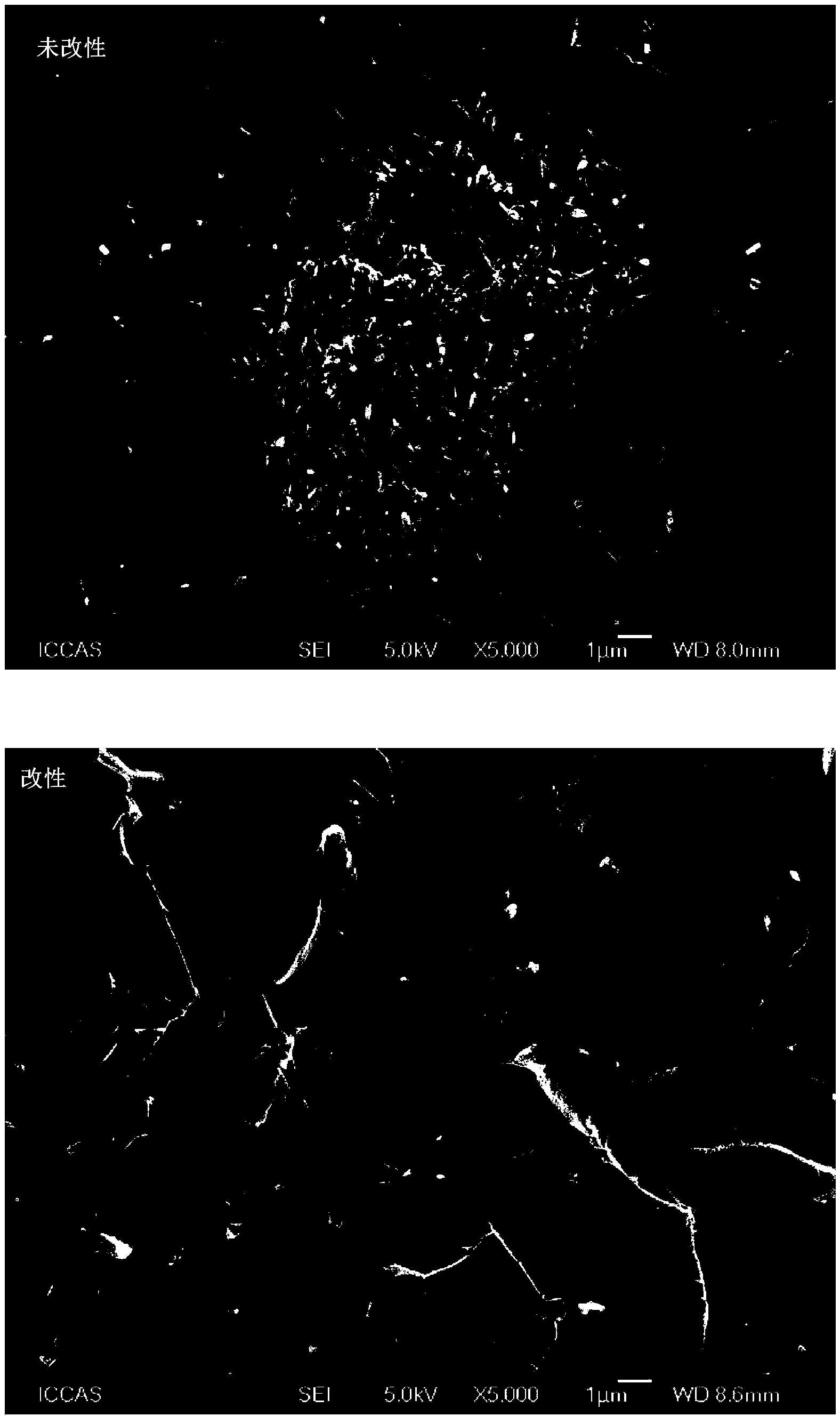

A halloysite nanotube and surface modification technology, which is applied in the field of preparation of nanocomposite materials, can solve the problems of not exhibiting mechanical properties, etc., and achieve the effects of strong effect, good dispersibility and compatibility, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Purification of halloysite nanotube particles:

[0044] The halloysite nanotube particles of 50g pulverized and sieved are mixed with 1250g deionized water to form a mixed solution, and 0.25g of sodium pyrophosphate is added, and stirred for 24 hours until forming a uniform suspension containing halloysite nanotube particles; The suspension was left to stand for 18 hours and layered, and the upper layer slurry after standing was put into a centrifuge, and centrifuged at 7000r / min for 30 minutes, and the precipitate solid obtained by centrifugation was placed in an oven at a temperature of Dry at 60°C until there is no change in quality, and then sieve with a 150-mesh sieve to obtain purified halloysite nanotube particles;

[0045] (2) Halloysite nanotube particles are modified with silane coupling agent:

[0046] Add 12g of the purified halloysite nanotube particles obtained in step (1) to 200mL of hydrochloric acid solution (2.5mol / L), ultrasonically disperse for ...

Embodiment 2

[0054] (1) Purification of halloysite nanotube particles:

[0055] Mix 30 g of halloysite nanotube particles crushed and sieved with 240 g of deionized water to form a mixed solution, add 0.03 g of sodium hexametaphosphate, and stir for 1 hour until a uniform suspension containing halloysite nanotube particles is formed; The suspension was left to stand for 48 hours, separated into layers, and the upper layer slurry after standing was put into a centrifuge, and centrifuged at 10000r / min for 3 minutes, and the precipitate solid obtained by centrifugation was placed in an oven at temperature Dry at 80°C until there is no change in quality, and then sieve with a 250-mesh sieve to obtain purified halloysite nanotube particles;

[0056] (2) Halloysite nanotube particles are modified with silane coupling agent:

[0057] Add 15g of the purified halloysite nanotube particles obtained in step (1) into 1000mL of hydrogen peroxide, ultrasonically disperse for 5 minutes and then stir at ...

Embodiment 3

[0065] (1) Purification of halloysite nanotube particles:

[0066] Mix 15 g of halloysite nanotube particles crushed and sieved with 180 g of deionized water to form a mixed solution, add 0.015 g of sodium polyacrylate with a molecular weight of 5000 g / mol, and stir for 10 hours until uniform halloysite nanotubes are formed. Suspension of particles; the suspension was left to stand for 8 hours, layered, and the upper layer slurry after standing was put into a centrifuge, and centrifuged at 4000r / min for 30 minutes, and the precipitate solid obtained by centrifugation was separated Dry in an oven at a temperature of 100°C until the quality does not change, and then sieve with a 150-mesh sieve to obtain purified halloysite nanotube particles;

[0067] (2) Halloysite nanotube particles are modified with silane coupling agent:

[0068] Add 10 g of the purified halloysite nanotube particles obtained in step (1) to 500 mL of concentrated sulfuric acid, ultrasonically disperse for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com