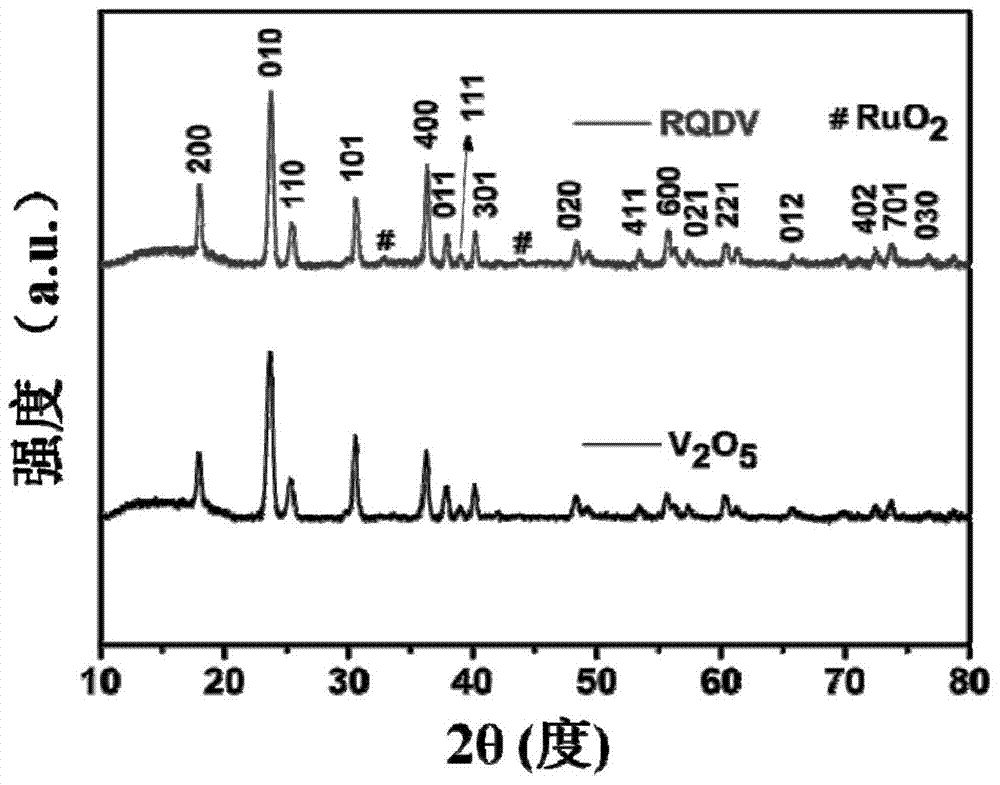

Ruthenium dioxide quantum dot modified vanadium pentoxide nano material as well as preparation method and application of material

A technology of vanadium pentoxide and nanomaterials, applied in the field of nanomaterials and electrochemistry, can solve problems such as low electronic conductivity, poor structural stability, slow ion diffusion rate, etc., and achieve high power density, high energy density, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

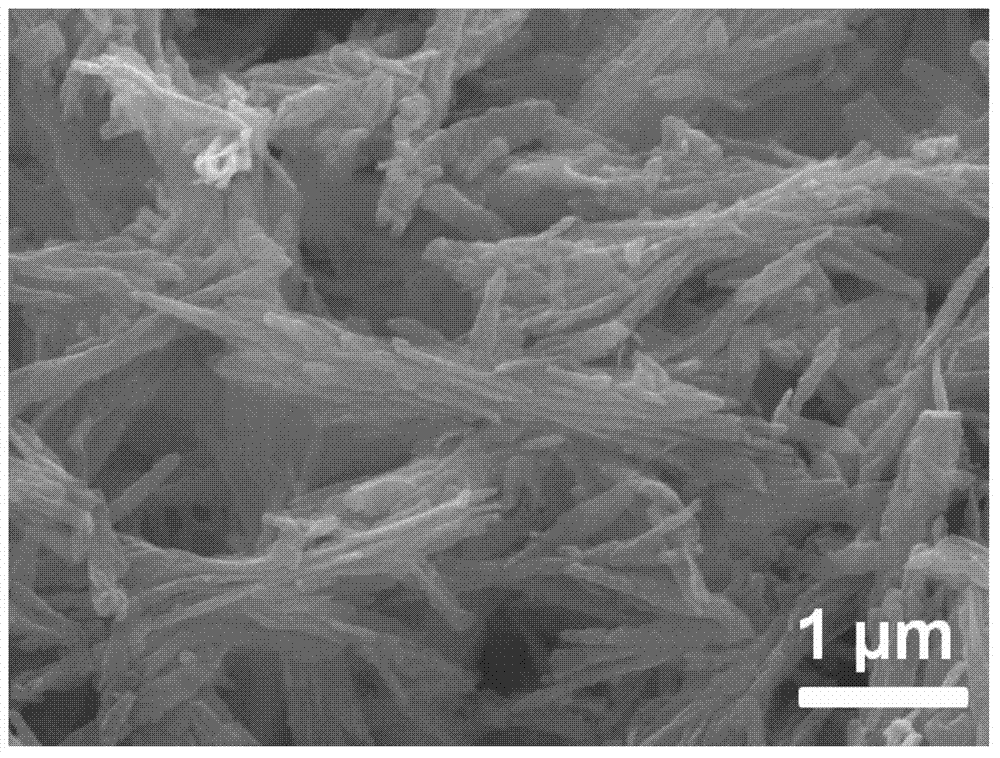

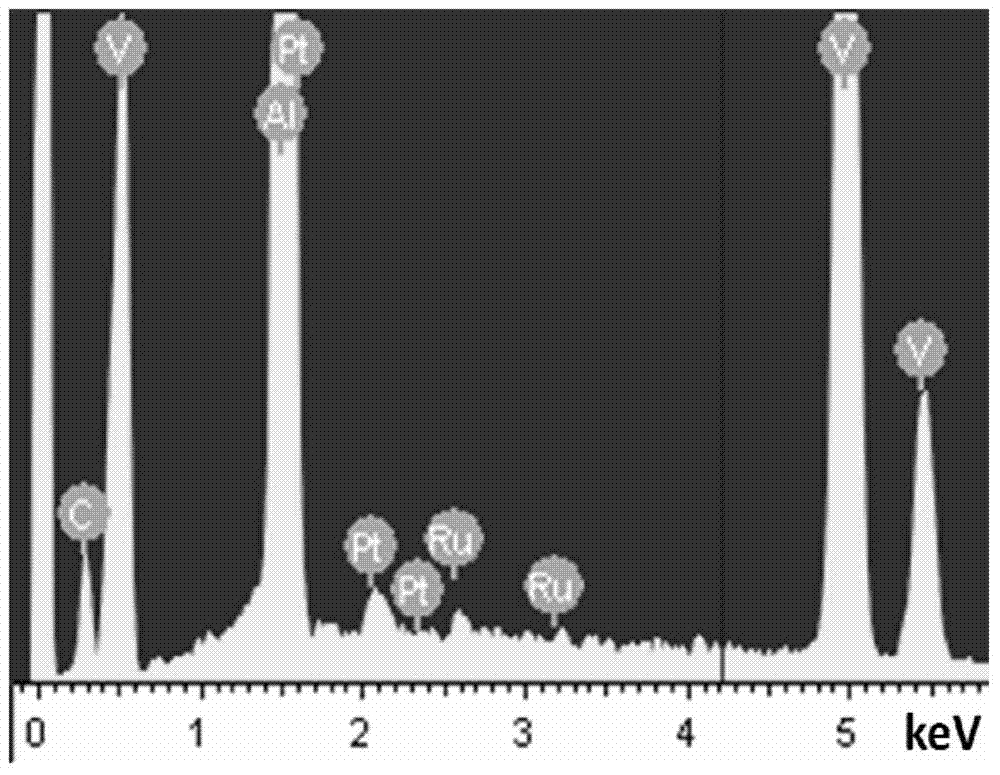

Embodiment 1

[0033] The preparation method of the vanadium pentoxide nanomaterial modified by bowtie-shaped ruthenium dioxide quantum dots, it comprises the steps:

[0034] 1) Dissolve 1 mmol of vanadium pentoxide powder in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and stir at room temperature for 10 minutes;

[0035] 2) Add 1.5 mmol ammonium dihydrogen phosphate to the solution obtained in step 1), and stir for 10 minutes;

[0036] 3) Add 0.08 mmol ruthenium chloride to the solution obtained in step 2), and continue to stir for 15 minutes;

[0037] 4) Transfer the solution obtained in step 3) into a 50mL reaction kettle, react at 180°C for 3 hours, take out the reaction kettle, and naturally cool to room temperature;

[0038] 5) Centrifuge the product obtained in step 4), wash it with alcohol for 3 times, and dry it in an oven at 70°C to obtain a bowtie-shaped vanadium pentoxide nanomaterial precursor modified with ruthenium dioxide quantum dots;

[0039] 6) The product o...

Embodiment 2

[0043] 1) Dissolve 1 mmol of vanadium pentoxide powder in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and stir at room temperature for 10 minutes;

[0044] 2) Add 1 mmol ammonium dihydrogen phosphate to the solution obtained in step 1), and stir for 20 minutes;

[0045] 3) Add 0.06 mmol ruthenium chloride to the solution obtained in step 2), and continue to stir for 15 minutes;

[0046] 4) Transfer the solution obtained in step 3) into a 50mL reaction kettle, react at 180°C for 3 hours, take out the reaction kettle, and naturally cool to room temperature;

[0047] 5) Centrifuge the product obtained in step 4), wash it with alcohol for 3 times, and dry it in an oven at 70°C to obtain a bowtie-shaped vanadium pentoxide nanomaterial precursor modified with ruthenium dioxide quantum dots;

[0048] 6) The product obtained in step 5) was placed in a muffle furnace and calcined at 400° C. for 3 hours to obtain a bowtie-shaped vanadium pentoxide nanomaterial modified wit...

Embodiment 3

[0051] 1) Dissolve 1 mmol of vanadium pentoxide powder in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and stir at room temperature for 10 minutes;

[0052] 2) Add 1.5 mmol ammonium dihydrogen phosphate to the solution obtained in step 1), and stir for 20 minutes;

[0053] 3) Add 0.1 mmol ruthenium chloride to the solution obtained in step 2), and continue stirring for 15 minutes;

[0054] 4) Transfer the solution obtained in step 3) into a 50mL reaction kettle, react at 180°C for 4 hours, take out the reaction kettle, and naturally cool to room temperature;

[0055] 5) Centrifuge the product obtained in step 4), wash it with alcohol for 3 times, and dry it in an oven at 70°C to obtain a bowtie-shaped vanadium pentoxide nanomaterial precursor modified with ruthenium dioxide quantum dots;

[0056] 6) The product obtained in step 5) was placed in a muffle furnace and calcined at 450° C. for 2 hours to obtain a bowtie-shaped vanadium pentoxide nanomaterial modified w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com