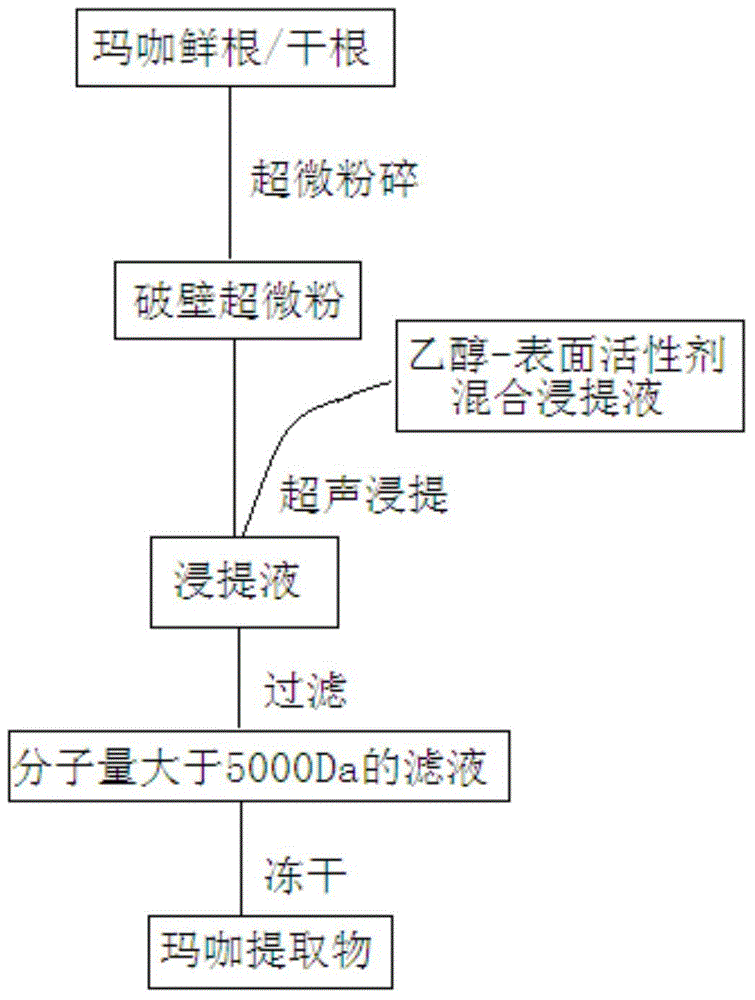

Preparation extraction process of Maca extract

A technology of maca extract and extraction process, which is applied in the direction of medical preparations containing active ingredients, plant raw materials, plant/algae/fungus/moss components, etc., and can solve organic solvent residues, extract component pollution, maca powder Inactivation and other problems, to achieve the effect of increasing the extraction rate, saving medicinal materials, and maintaining color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

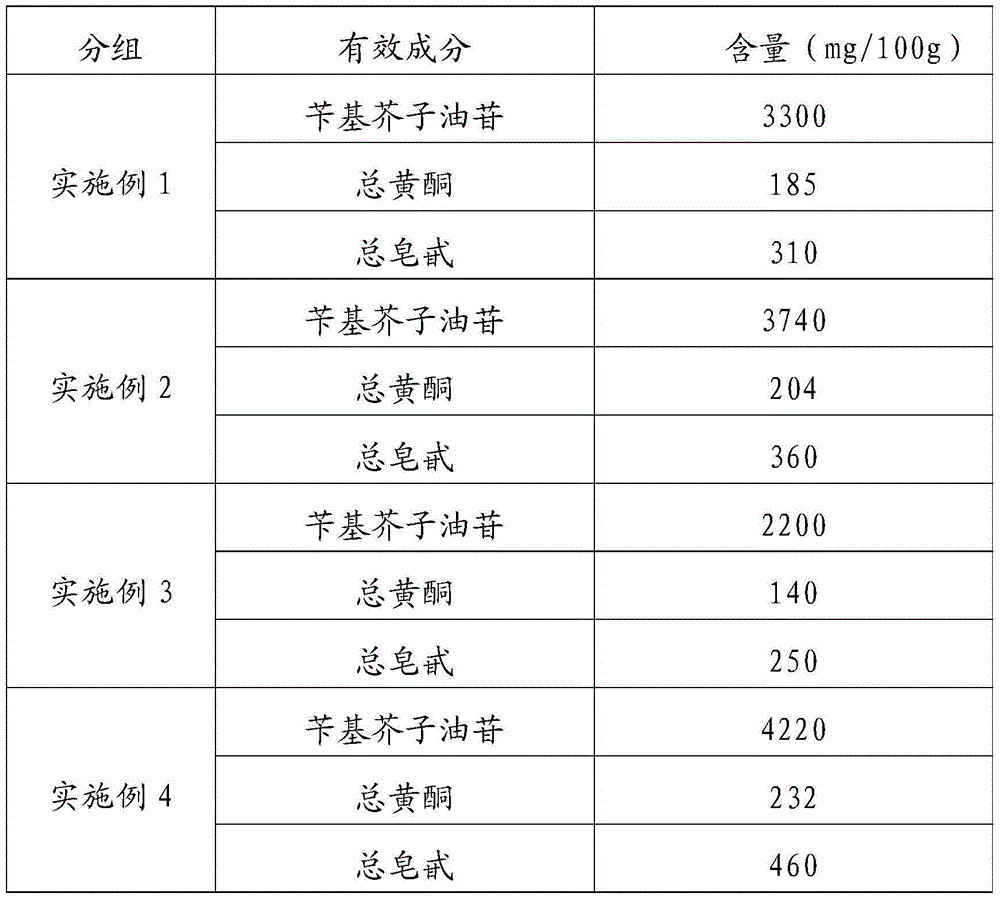

Examples

Embodiment 1

[0035] Wash the maca root and put it into the ultra-high pressure equipment, set the pressure to 100Mpa, and process for 15 minutes. The obtained Maca root is added to a superfine powder high-speed universal pulverizer for wall-breaking treatment to obtain a 600-mesh Maca broken-wall superfine powder. According to the solid-to-liquid ratio of 1:10, add 50v / v% ethanol solution, and add 0.2% polyoxyethylene sorbitan monolaurate surfactant of the total weight of the solution, put it into the ultrasonic equipment, and set the ultrasonic frequency to 50Hz, the extraction temperature is 20°C, the extraction is stirred for 60min, the stirring speed is 30rpm, the stirring time is 10min, and the rotating speed is 2000rpm, and the filtrate is collected. The obtained filtrate is processed through 1μm and 0.2μm plate and frame filter equipment successively, extracted twice in total, and the filtrate is combined. The obtained clarified filtrate is treated by ultrafiltration membrane filtra...

Embodiment 2

[0037] Wash the maca root and put it into the ultra-high pressure equipment, set the pressure to 300Mpa, and process for 10 minutes. The maca root obtained is added to a superfine powder high-speed universal pulverizer for wall-breaking treatment to obtain a 300-mesh maca broken-wall superfine powder. According to the solid-liquid ratio of 1:20, add 70v / v% ethanol solution, and add 1% polyoxyethylene sorbitan monopalmitate of the total weight of the solution, put it into the ultrasonic equipment, set the ultrasonic frequency to 60Hz, The extraction temperature was 30°C, and the mixture was stirred after 30 minutes of extraction at a stirring speed of 15 rpm for 20 minutes, centrifuged at a rotating speed of 5000 rpm, and the filtrate was collected. The obtained filtrate was processed through 1μm and 0.2μm plate and frame filter equipment in turn, extracted twice, and the filtrate was combined. The obtained clarified filtrate was treated by ultrafiltration membrane filtration e...

Embodiment 3

[0039] Wash the maca root and put it into the ultra-high pressure equipment, set the pressure to 500Mpa, and process for 5 minutes. The obtained Maca root is added to a superfine powder high-speed universal pulverizer for wall-breaking treatment to obtain 800-mesh Maca broken-wall superfine powder. According to the solid-liquid ratio of 1:5, add 70v / v% ethanol solution, and add 0.6% polyoxyethylene sorbitan monostearate of the total weight of the solution, put it into the ultrasonic equipment, and set the ultrasonic frequency to 55Hz , the extraction temperature was 25°C, and the mixture was stirred after 40 minutes of extraction at a stirring speed of 25 rpm for 16 minutes, centrifuged at a rotating speed of 3000 rpm, and the filtrate was collected. The obtained filtrate was processed through 1μm and 0.2μm plate-and-frame filtration equipment successively, extracted twice in total, and the filtrate was combined. The obtained clarified filtrate was treated by ultrafiltration mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com