Novel low-temperature SCR (Selective Catalytic Reduction) catalyst based on tetragonal-phase zirconium oxide carrier and preparation method

A technology of SCR catalyst and phase zirconia, which is applied in the direction of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems affecting texture, catalytic activity and catalytic selectivity, no one mentioned, and the existence of preparation technology Blank and other problems, to achieve the effect of improving catalytic activity, reducing preparation cost, and low loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

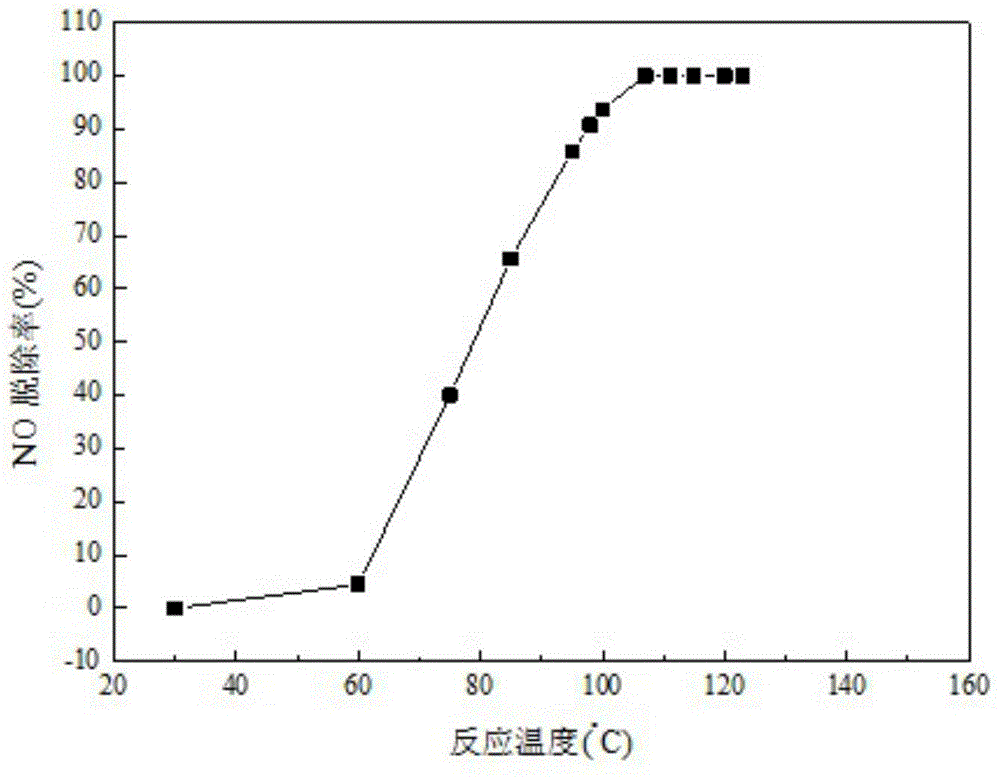

Embodiment 1

[0033] (1) Take ZrOCl 2 ·8H 2 O(AR) is 15.388g, Y(NO 3 ) 3 ·6H 2 O(AR) is 0.5081g, PEG-4000(CP) is 0.32g, and it is configured as a mixed solution. Under the condition of rapid stirring, slowly drop 0.5mol / L ammonia solution into the prepared solution at a rate of 1mL / min until the pH=9.5, after aging for 12 hours, wash with water and alcohol (absolute ethanol, AR) Later until Cl - Removed, dried for 12 hours, and ground to obtain white precursor powder. The precursor powder was heated at a rate of 5°C / min without a protective atmosphere, kept at 650°C for 2 hours, and then naturally cooled to obtain tetragonal zirconia.

[0034] (2) Take 10g of tetragonal zirconia powder obtained in (1), 2.26mL of 50% manganese nitrate solution (Sinopharm, AR), Ce(NO 3 ) 3 ·6H 2 O is 2.5g, according to the equal-volume impregnation method, dissolved in deionized water, ultrasonically treated for 30min, impregnated for 6h under rapid stirring conditions, dried at 120°C for 12h, and he...

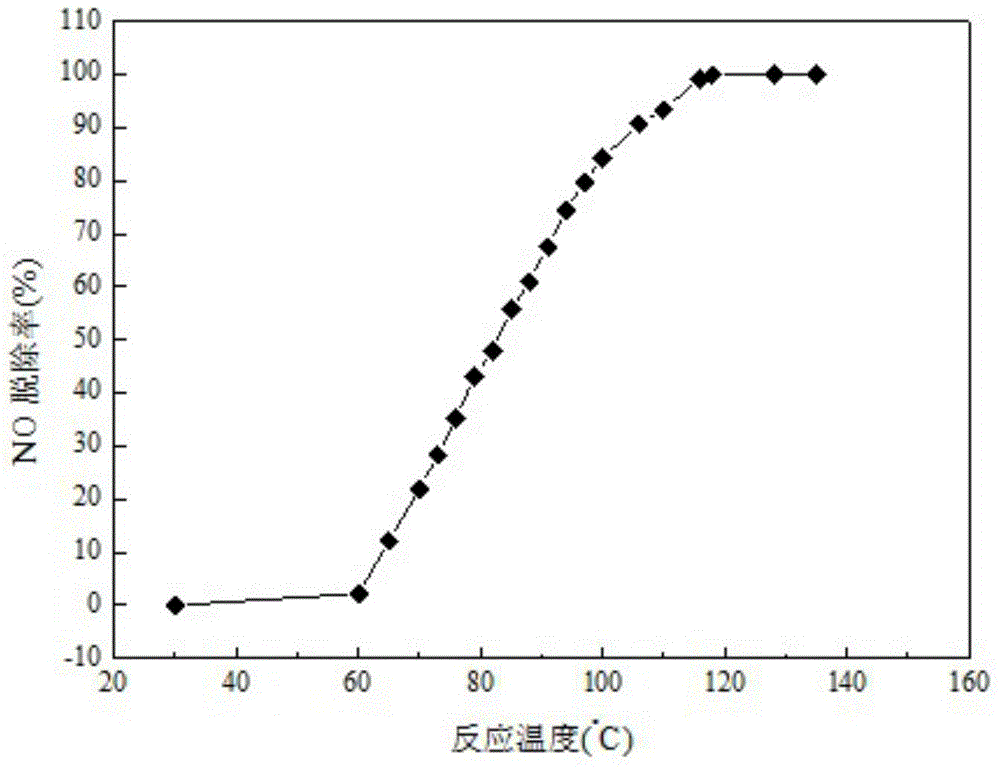

Embodiment 2

[0038] (1) Take ZrOCl 2 ·8H 2 O(AR) is 15.388g, Y(NO 3 ) 3 ·6H 2 O(AR) is 0.5081g, PEG-4000(CP) is 0.30g, and it is configured as a mixed solution. Under rapid stirring conditions, slowly drop 0.5mol / L ammonia solution into the prepared solution at a rate of 1mL / min until pH = 10, after aging for 24 hours, wash with water and alcohol (absolute ethanol, AR) Later until Cl - Removed, dried for 12 hours, and ground to obtain white precursor powder. The precursor powder was heated at a rate of 5°C / min without a protective atmosphere, kept at 650°C for 2 hours, and then naturally cooled to obtain a tetragonal zirconia powder.

[0039] (2) Take 10g of tetragonal zirconia powder obtained in (1), 1.13mL of 50% manganese nitrate solution (Sinopharm, AR), Ce(NO 3 ) 3 ·6H 2 O is 1.25g, according to the equal-volume impregnation method, dissolved in deionized water, ultrasonically treated for 30min, impregnated for 6h under rapid stirring conditions, dried at 120°C for 12h, and h...

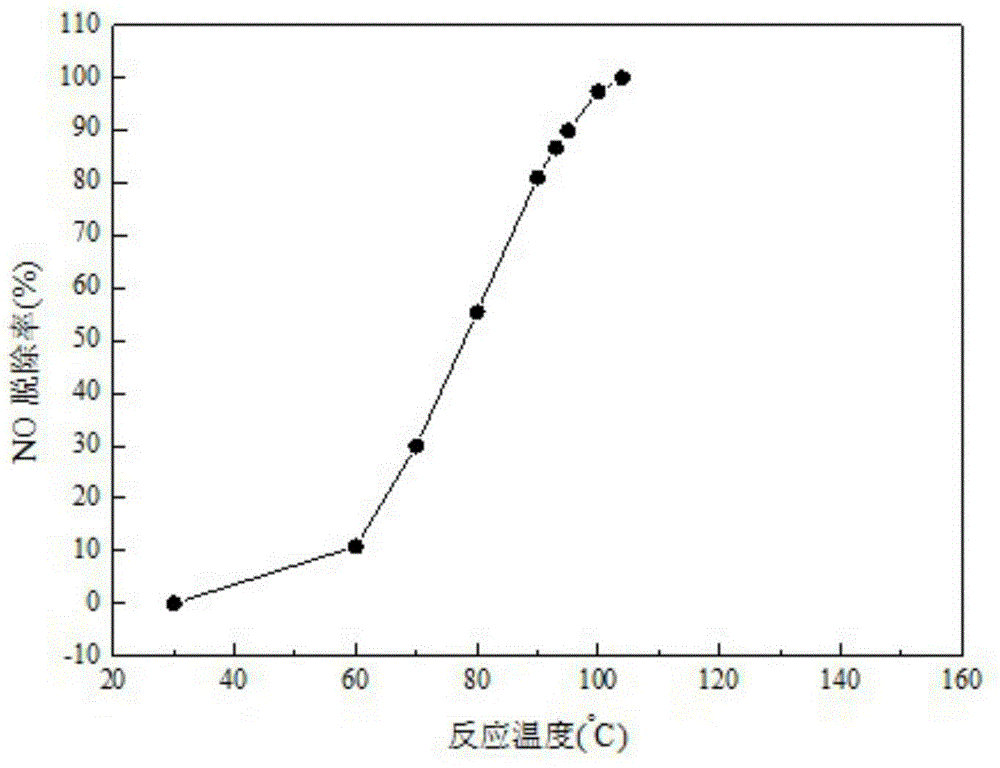

Embodiment 3

[0043] (1) Take ZrOCl 2 ·8H 2 O(AR) is 15.871g, Y(NO 3 ) 3 ·6H 2 O(AR) is 0.4213g, PEG-4000(CP) is 0.28g, and it is configured as a mixed solution. Under the condition of rapid stirring, slowly drop 0.5mol / L ammonia solution into the prepared solution at a rate of 1mL / min until the pH=9.5, after aging and precipitation for 24 hours, wash with water and alcohol (absolute ethanol, AR) Later until Cl - Removed, dried for 12 hours, and ground to obtain white precursor powder. The precursor powder was heated at a rate of 5°C / min without a protective atmosphere, kept at 650°C for 2 hours, and then naturally cooled to obtain a tetragonal zirconia powder.

[0044] (2) Take 10g of tetragonal zirconia powder obtained in (1), 3.39mL of 50% manganese nitrate solution (Sinopharm, AR), Ce(NO 3 ) 3 ·6H 2 O is 3.75g, according to the equal-volume impregnation method, dissolved in deionized water, ultrasonically treated for 30min, impregnated for 6h under rapid stirring conditions, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com