Flexible transparent conductive film based on nano-silver wire and preparation method thereof

A technology of transparent conductive film and nano-silver wire, which is applied to conductive layer on insulating carrier, cable/conductor manufacturing, circuit and other directions, can solve the problems of complex preparation of transparent conductive film, many processes and high cost, and achieves low price and high cost. The effect of electrical conductivity and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

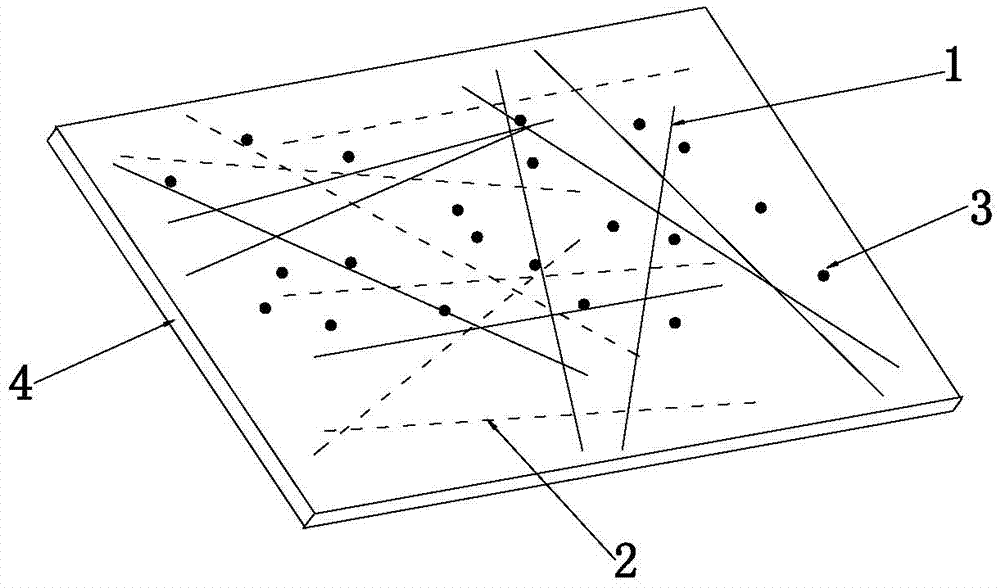

[0034] A flexible transparent conductive film based on nano-silver wires, the transmittance of light is above 87%, the square resistance is 10~200ohm / sq, and the change rate of square resistance and transmittance after bending at least twice is less than 1% or remain unchanged. It is mainly composed of a network layer 1 composed of nano-silver wires, a nano-particle filling structure 2 and an optical adhesive layer 4. The nano-silver wires are distributed on the optical adhesive layer to form a network-like conductive structure, and at the same time there are no less than 10% Nano-silver wires are embedded in the optical glue layer, which can ensure the smoothness of the surface. The network layer can be formed on the glass substrate by spin-coating the dispersion liquid of nano-silver wires without heating and baking. Nano-particles (such as nano-titanium dioxide, One or more of nano-zirconia, nano-silica or nano-alumina nanoparticles) are filled in the conductive network com...

specific example 1

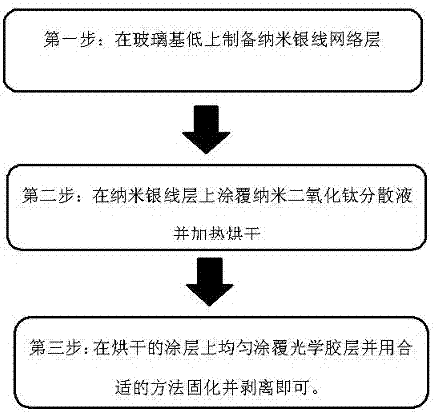

[0036] refer to figure 1 ,2,3

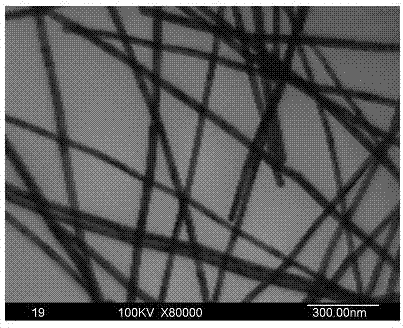

[0037] Silver nanowires with a concentration of 0.2% (such as image 3 ) The dispersion liquid is uniformly coated on the glass through a homogenizer, and placed in the air for 5-10 minutes to completely evaporate the solvent. A uniform network of nano-silver wires is formed on the glass.

[0038] The concentration of 0.5% nano-titanium dioxide dispersion is uniformly coated on the nano-silver wire network layer. Baking at 80°C for 30s forms nano-titanium dioxide filled nano-silver wire network structure.

[0039] A layer of optical UV glue is spin-coated on the nano-titanium dioxide-filled nano-silver wire network structure, and irradiated with an ultraviolet lamp for 2-5 minutes. After curing is complete, the film is peeled off the glass.

[0040] The electrical conductivity of the film was tested by the four-probe method to test the sheet resistance, and the transmittance of the prepared film was tested by a spectrophotometer. The flexibi...

specific example 2

[0042] refer to figure 1 , 2, 4

[0043] Silver nanowires with a concentration of 0.7% (such as Figure 4 ) The dispersion liquid is uniformly coated on the glass through a homogenizer, and placed in the air for 5-10 minutes to completely evaporate the solvent. A uniform network of nano-silver wires is formed on the glass.

[0044] The nano zirconium dioxide dispersion liquid with a concentration of 0.8% is uniformly coated on the nano silver wire network layer. Baking at 80°C for 30s to form a network structure of nano-zirconium dioxide filled nano-silver wires.

[0045] A layer of optical gel is spin-coated on the network structure of nano-zirconia filled nano-silver wires, and dried at 50°C / 2h. After curing is complete, the film is peeled off from the glass.

[0046] The electrical conductivity of the film was tested by the four-probe method to test the sheet resistance, and the transmittance of the prepared film was tested by a spectrophotometer. For the flexibility t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com