Polyamino acid adjusted and controlled super-hydrophobic surface material constructed in a biomineralization way and the preparation method thereof

A technology of super-hydrophobic surface and polyamino acid, which is applied in the direction of special surface, nanostructure manufacturing, and device for coating liquid on the surface, etc. It can solve the problem of wettability of the final material without reporting the crystal morphology and the inability to form a stable functional surface , weak force and other problems, to achieve the effect of controllable product size and shape, simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

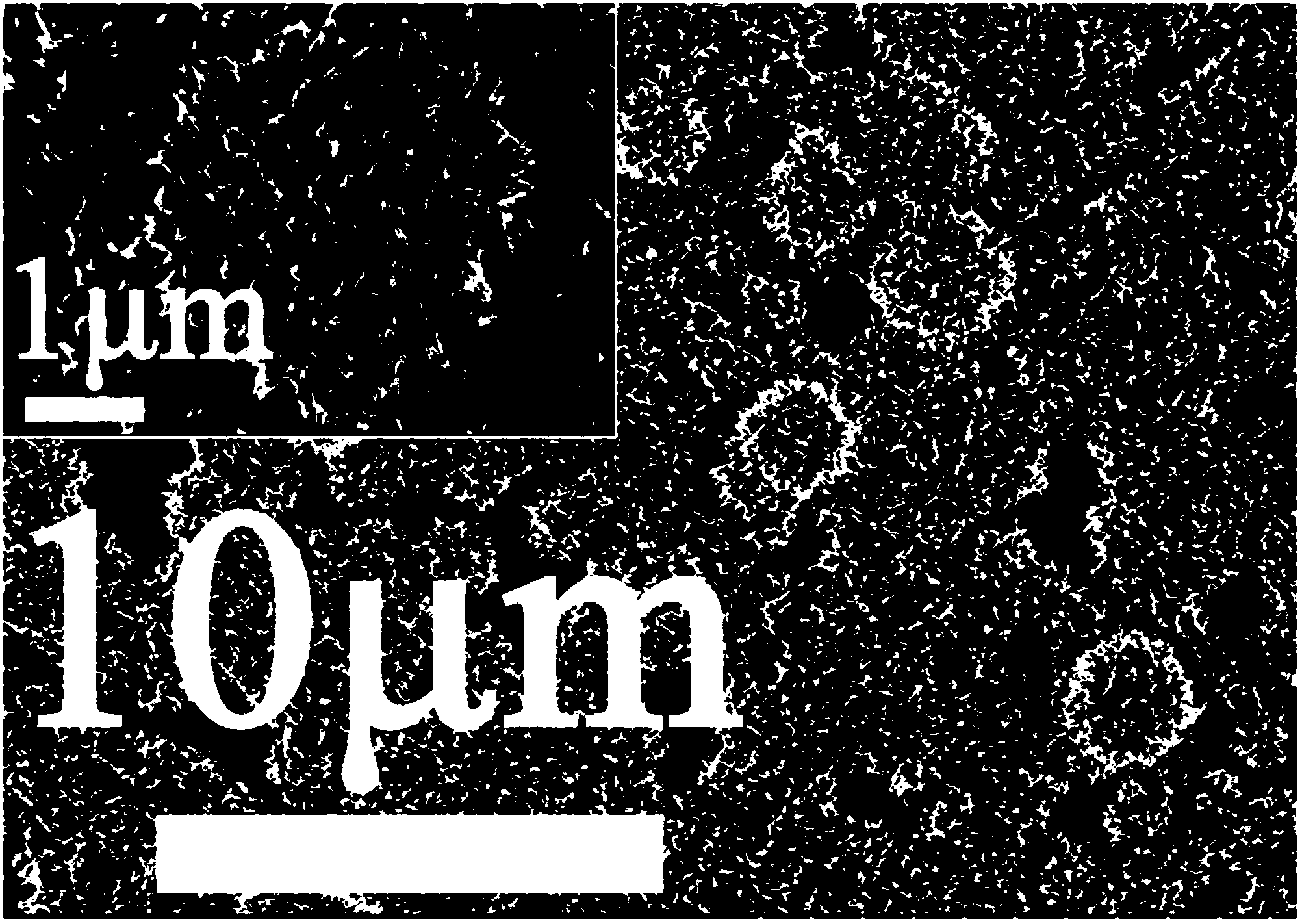

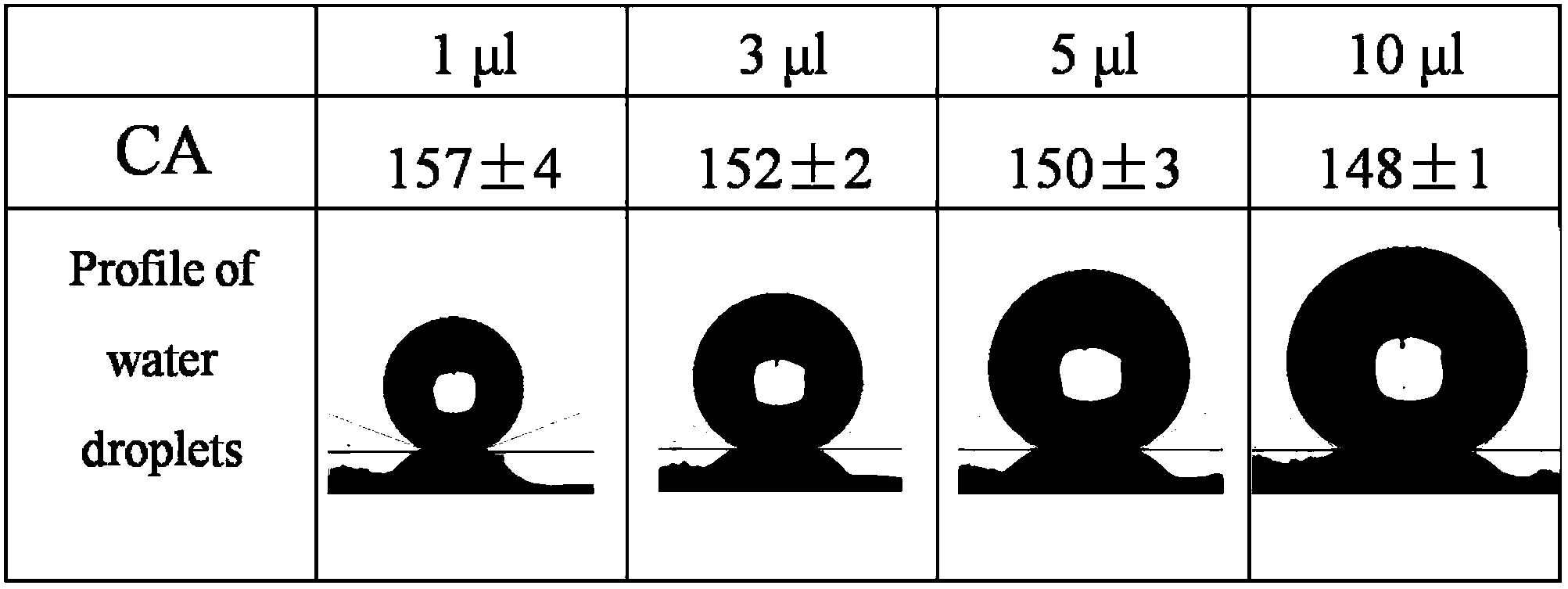

Embodiment 1

[0032]The surface of the glass plate was treated with ethanol-n-hexane, plasma, nitric acid washing solution, concentrated sulfuric acid, and deionized water repeatedly for use. Add the prepared 2mmol / L calcium chloride solution and 0.5g / L polyglutamic acid solution into a 10mL small beaker, then put the previously treated small glass plate into the small beaker, and seal it with parafilm Poke a few small holes in it with a needle. Then put 10g of inorganic ammonium salt into another small beaker and seal it with parafilm, and poke several small holes on it. Put the previous beaker into a desiccator at the same time, take out the glass plate after the reaction time is 24 hours at a temperature of 25°C for post-treatment. After the glass plate is taken out, the surface is repeatedly washed with deionized water for 1-6 times, and finally the glass plate is vacuum-dried. Put the dry glass plate with inorganic calcium salt into the gold spraying instrument to spray gold for 30s,...

Embodiment 2

[0036] The surface of the glass plate was treated with ethanol-n-hexane, plasma, nitric acid washing solution, concentrated sulfuric acid, and deionized water repeatedly for use. Add the prepared 5mmol / L calcium chloride solution and 0.5g / L polyserine solution into a 100mL small beaker, then put the previously treated small glass plate into the small beaker, seal it with a parafilm film and place it in the Poke a few small holes with a needle. Then put 9g of inorganic ammonium salt into another small beaker and seal it with parafilm, and poke several small holes on it. Put the previous beaker into a desiccator at the same time, take out the glass plate after the reaction time is 48h at a temperature of 35°C for post-treatment. After the glass plate is taken out, the surface is repeatedly washed with deionized water for 1-6 times, and finally the glass plate is vacuum-dried. Put the dry glass plate with inorganic calcium salt into the gold spraying instrument to spray gold fo...

Embodiment 3

[0038] The surface of the glass plate was treated with ethanol-n-hexane, plasma, nitric acid washing solution, concentrated sulfuric acid, and deionized water repeatedly for use. Add the prepared 10mmol / L calcium chloride and sodium dihydrogen phosphate solution and 0.6g / L polyglutamic acid solution into a 100mL small beaker, then put the previously treated small glass plate into the small beaker, and use parafilm After the film seals it, several small holes are poked on it with a needle. Then put 8g of inorganic ammonium salt into another small beaker and seal it with parafilm, and poke several small holes on it. Put the previous beaker into a desiccator at the same time, take out the glass plate after the reaction time is 24 hours at a temperature of 30°C for post-treatment. After the glass plate is taken out, the surface is repeatedly washed with deionized water for 1-6 times, and finally the glass plate is vacuum-dried. Put the dry glass plate with inorganic calcium salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com