A cellulose hybrid, preparation method and its application

A cellulose mixed ester and cellulose technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as uncontrollable product structure, environmental pollution, severe degradation of cellulose, etc., and achieve free volume fraction Large, high mechanical strength, high solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

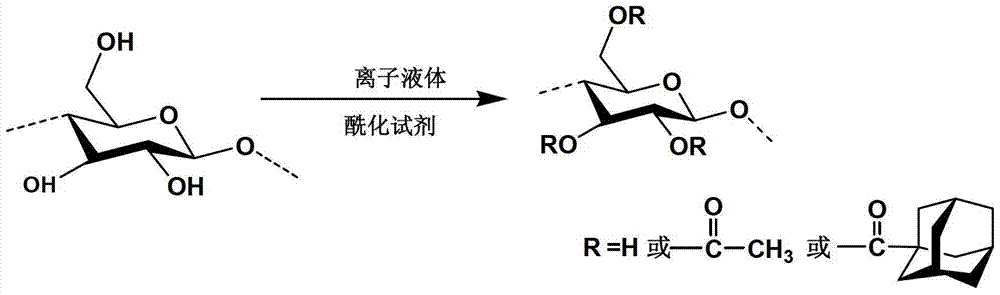

[0037] The synthetic method of adamantane cellulose acetate mixed ester comprises the following steps:

[0038] a. Add 2 g of cellulose to 48 g of allylmethylimidazolium chloride ionic liquid, and mechanically stir at 80° C. for 2 hours to dissolve the cellulose; the mass concentration of the cellulose is 4%.

[0039] b. Add 3.4 g of co-solvent pyridine and stir for 5 minutes. The molar ratio of pyridine to anhydroglucose units in cellulose is 3.5:1; add acetic anhydride and adamantanecarbonyl chloride at the same time, stir mechanically for 2 hours, and maintain the temperature at 80°C; adamantine The molar ratio of alkanoyl chloride and acetic anhydride to anhydroglucose units in cellulose is 1:1

[0040] c. Add ethanol to precipitate the product, vacuum filter and wash.

[0041] The precipitate obtained in step c was purified with DMSO, washed with water, filtered under reduced pressure, and dried.

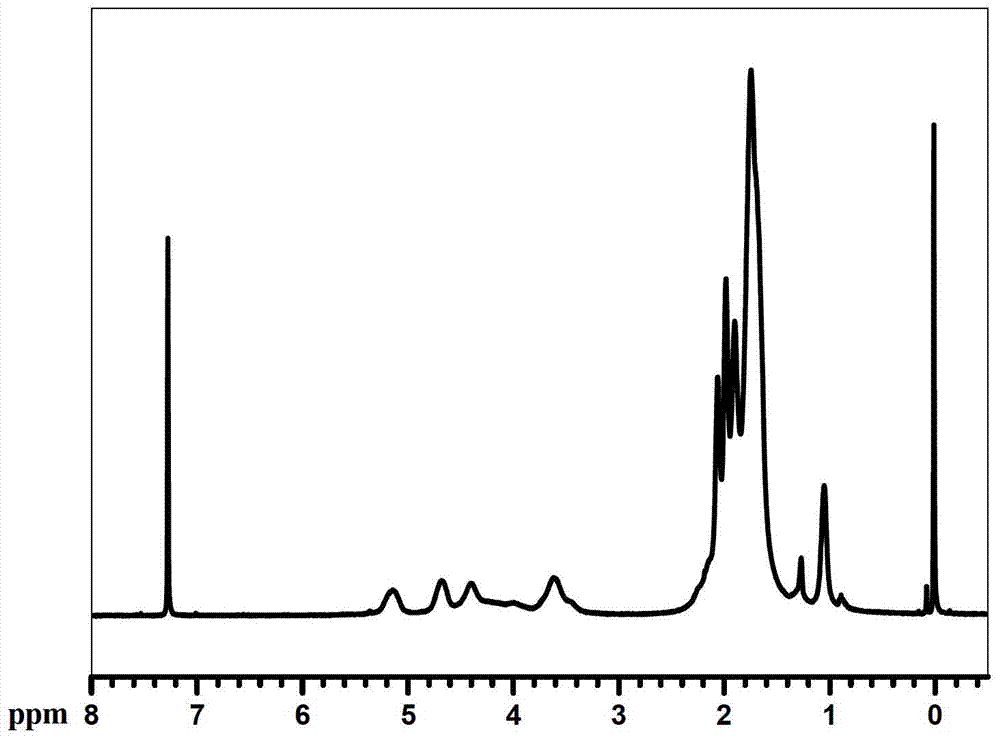

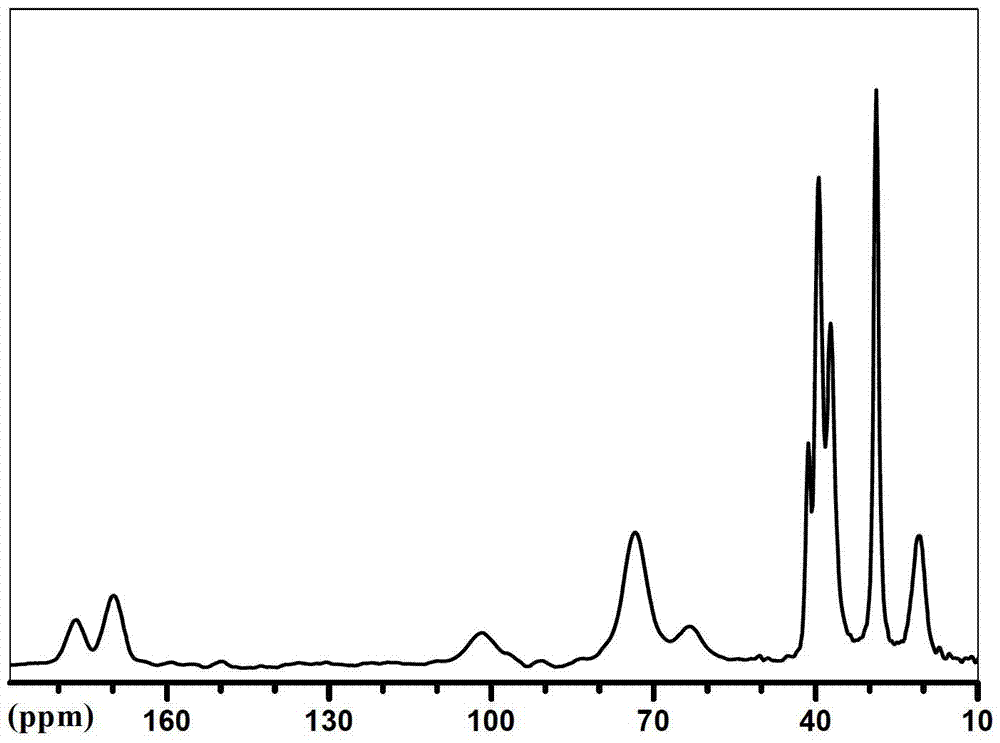

[0042] According to NMR calculation, the total substitution degree of the ...

Embodiment 2

[0044] Same as Example 1, the difference is that the ionic liquid is butylmethylimidazole acetate ionic liquid, the co-solvent is imidazole, the molar ratio of imidazole to the anhydroglucose unit in the cellulose is 3:1, first add adamantane carboxylic acid chloride, stir After 1 hour, add acetic anhydride and stir mechanically for 1 hour. The molar ratio of acetic anhydride and adamantanecarbonyl chloride to the anhydroglucose unit in the cellulose is 1:1, and the precipitating agent is isopropanol. The total substitution degree of the obtained adamantanecarboxylate mixed ester was 0.79, the substitution degree of the acetate group was 0.63, and the substitution degree of the adamantanecarboxylate group was 0.16.

Embodiment 3

[0046] Same as Example 1, the difference is that the ionic liquid is ethylmethylimidazolium chloride ionic liquid, the co-solvent is ethylenediamine, the molar ratio of ethylenediamine to the anhydroglucose unit in the cellulose is 3:1, first add acetic anhydride , after stirring for 1h, add adamantanecarbonyl chloride again, mechanically stir 1h, the mol ratio of adamantanecarbonyl chloride and the anhydroglucose unit in the cellulose is 1:1, and the mol ratio of the anhydroglucose unit in the acetic anhydride and the cellulose is 2: 1. The total degree of substitution of the obtained mixed cellulose acetate adamantane carboxylate was 1.68, the degree of substitution of the acetate group was 1.56, and the degree of substitution of the adamantane carboxylate was 0.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com