Preparation method of hyperbranched modified azobenzene and acrylate copolymer emulsion

A technology of acrylate and copolymerization emulsion, which is applied in the direction of chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of rare reports on copolymerization reactions, and achieve the effects of rich raw material sources, expanded application range, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

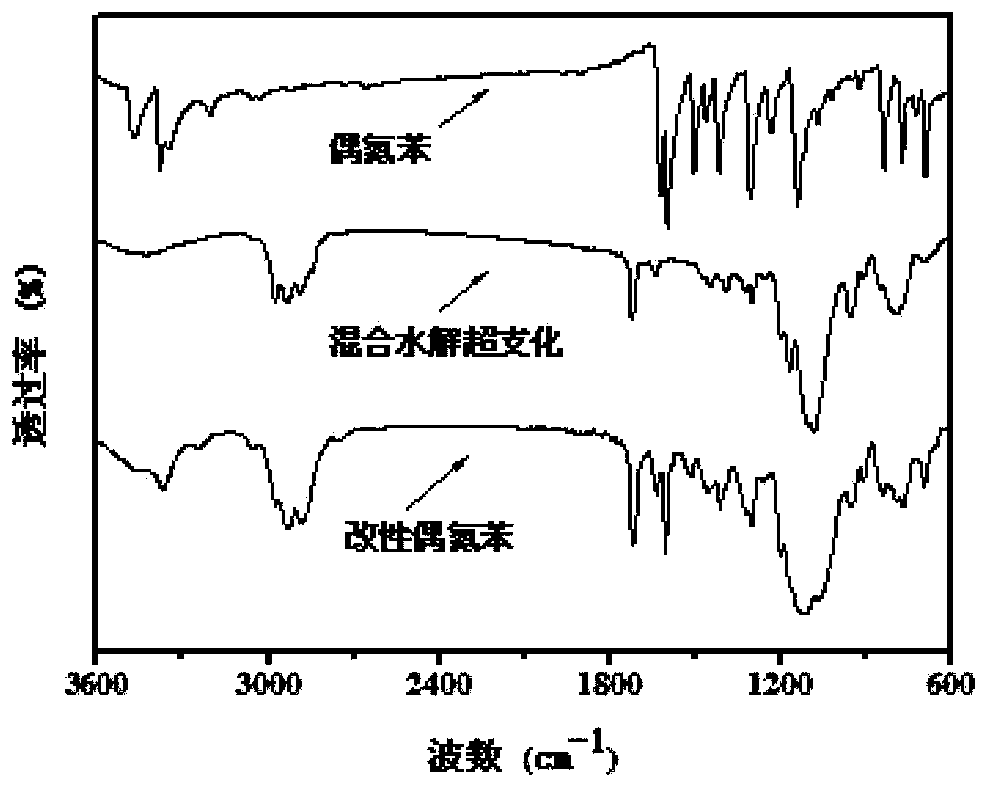

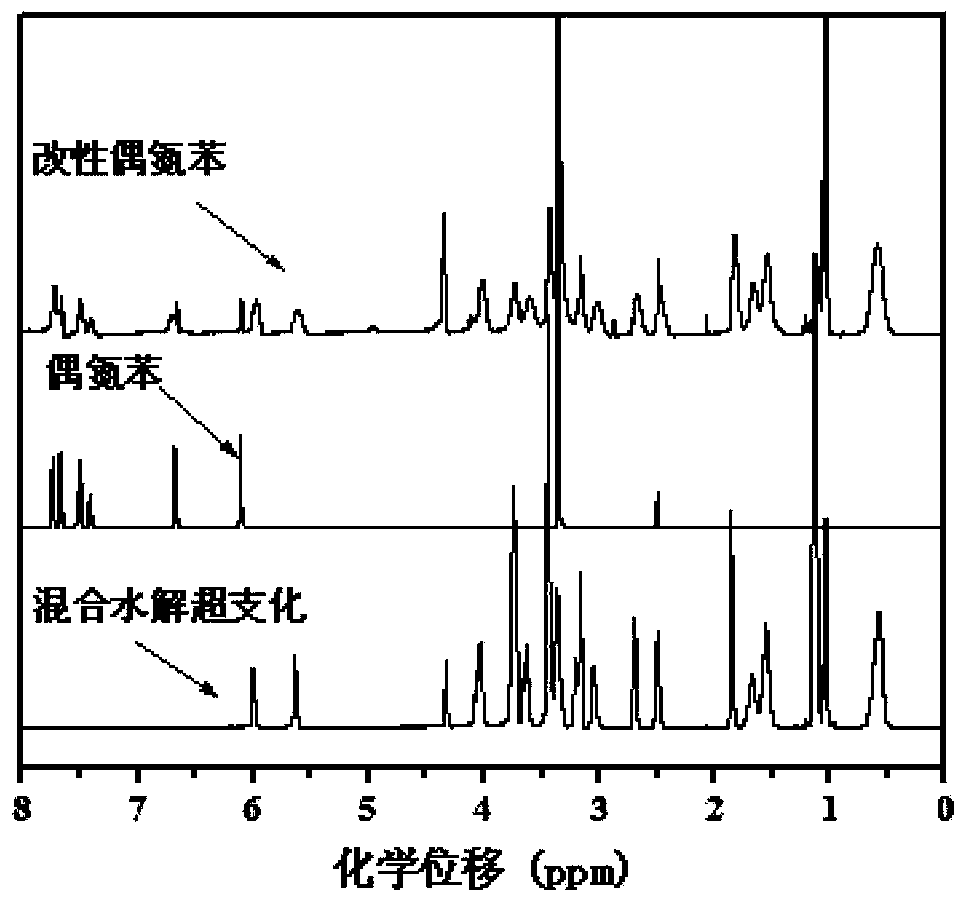

[0043] 1. Preparation of mixed hydrolysis hyperbranched system

[0044] Add 27.5g of 3-glycidyloxypropyltrimethoxysilane, 23.6g of 3-methacryloyloxypropyltrimethoxysilane, 55mL of absolute ethanol into a three-necked flask, magnetic stirring, N 2 Under protection, the temperature was raised to 65°C, and reflux condensed at this temperature. 5.82 g of distilled water was added dropwise, and a certain amount of sodium hydroxide was added to control the pH of the system to be 11, and the rotating speed was 150 rpm to stir and keep warm for 4.5 hours. After the reaction is over, distill under reduced pressure at 80°C to obtain a mixed hydrolysis hyperbranched system. The structural formula is shown in Figure 5 ,in

[0045]

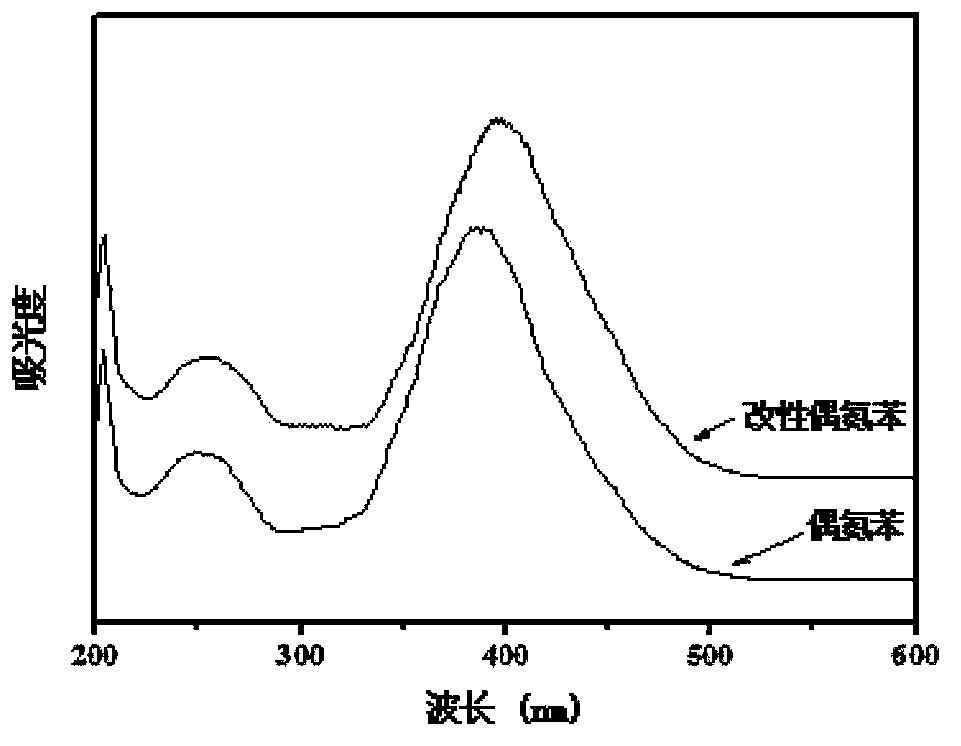

[0046] 2. Preparation of hyperbranched modified azobenzene

[0047] Weigh 13.5g of the mixed hydrolysis hyperbranched system into a three-necked flask, add 31mL of absolute ethanol, stir magnetically to form a uniform solution, add dropwise 18mL of abso...

Embodiment 2

[0057] 1. Preparation of mixed hydrolysis hyperbranched system

[0058] According to the technical scheme of Example 1, a mixed hydrolysis hyperbranched system was prepared.

[0059] 2. Preparation of hyperbranched modified azobenzene

[0060] Prepare hyperbranched modified azobenzene according to the technical scheme of Example 1.

[0061] 3. Copolymerization of hyperbranched modified azobenzene and acrylate

[0062] Take 10.2g of methyl methacrylate, 23.2g of butyl acrylate, 0.8g of sodium lauryl sulfate, 0.72g of OP-10, 0.12g of hyperbranched modified azobenzene, and 85mL of deionized water. Pre-emulsify on the agitator with a rotation speed of 400r / min. Weigh 0.21g of initiator ammonium persulfate to prepare a 0.02g / mL aqueous solution. After half an hour of pre-emulsification, take 1 / 4 each of the pre-emulsion and the ammonium persulfate solution into a four-necked bottle, and react under stirring at a speed of 250r / min. The remaining pre-emulsion was dispersed at hi...

Embodiment 3

[0064] 1. Preparation of mixed hydrolysis hyperbranched system

[0065] According to the technical scheme of Example 1, a mixed hydrolysis hyperbranched system was prepared.

[0066] 2. Preparation of hyperbranched modified azobenzene

[0067] Prepare hyperbranched modified azobenzene according to the technical scheme of Example 1.

[0068] 3. Copolymerization of hyperbranched modified azobenzene and acrylate

[0069] Take 10.2g of methyl methacrylate, 23.2g of butyl acrylate, 0.8g of sodium lauryl sulfate, 0.72g of OP-10, 0.24g of hyperbranched modified azobenzene, and 85mL of deionized water. Pre-emulsify on the agitator with a rotation speed of 400r / min. Weigh 0.21g of initiator ammonium persulfate to prepare a 0.02g / mL aqueous solution. After half an hour of pre-emulsification, take 1 / 4 each of the pre-emulsion and the ammonium persulfate solution into a four-necked bottle, and react under stirring at a speed of 250r / min. The remaining pre-emulsion was dispersed at hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com