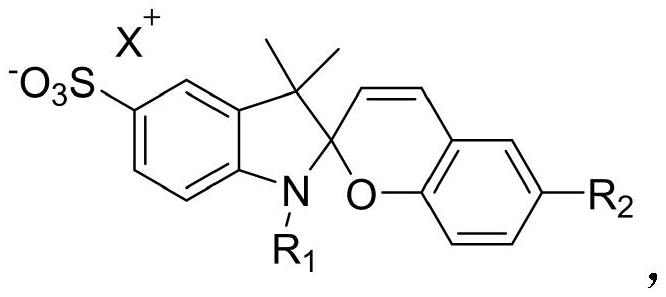

Water-soluble photochromic compound as well as preparation method and application thereof

A photochromic and compound technology, applied in the field of dyeing and finishing chemistry, can solve the problems of lack of photochromic dyes, poor color fastness to washing, low solubility, etc., to reduce the harm to human health, good soaping fastness, Enhanced Solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

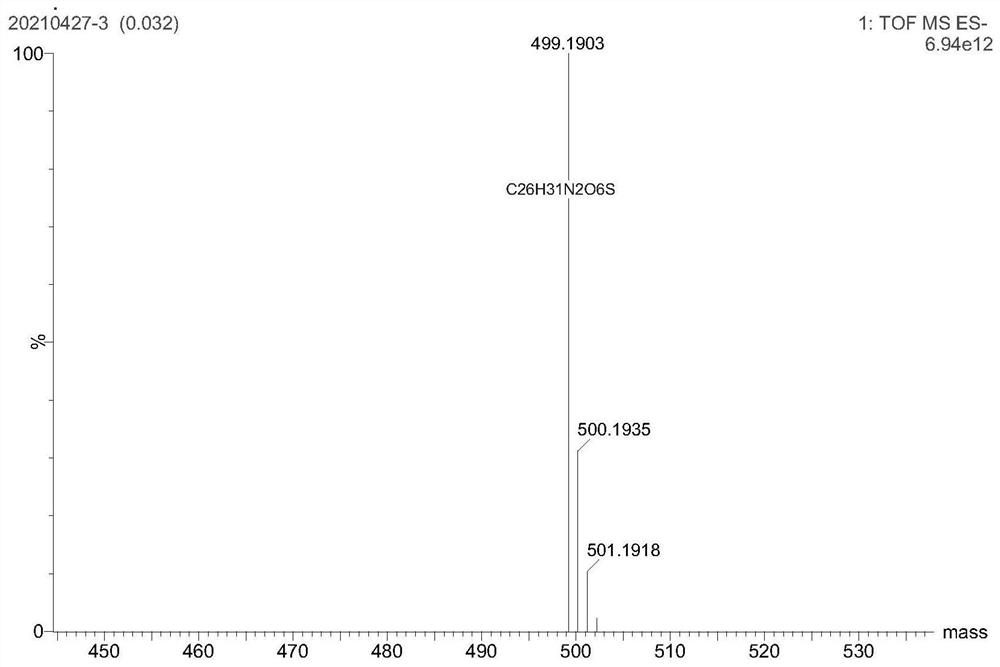

[0037] A water-soluble photochromic compound and a preparation method thereof, using phenylhydrazine-4-sulfonic acid, 3-methyl-2-butanone, potassium hydroxide, 5-nitrosalicylaldehyde and methyl iodide as raw materials, including Follow the steps below:

[0038] 1. Dissolve phenylhydrazine-4-sulfonic acid (4.0g, 20mmol) and 3-methyl-2-butanone (3.4g, 40mmol) in glacial acetic acid, heat to 120°C in a round bottom flask, nitrogen atmosphere Reflux under protection and react for 14h.

[0039] 2. Ethyl acetate was added to wash twice and the pink solid powder was filtered out and dried in vacuum.

[0040] 3. Dissolve the powder in methanol, add saturated potassium hydroxide solution in isopropanol dropwise, stir in a beaker at room temperature for 2 hours, filter, and dry indole sulfonate.

[0041] 4. Indole sulfonate (4.0g, 14mmol) and methyl iodide (3.0g, 21mmol) were dissolved in acetonitrile, heated to 80°C in a round bottom flask, refluxed for 48h under nitrogen atmosphere,...

Embodiment 2

[0044] A water-soluble photochromic compound and a preparation method thereof, using phenylhydrazine-4-sulfonic acid, 3-methyl-2-butanone, potassium hydroxide, 5-nitrosalicylaldehyde and bromooctane as raw materials, Including the following steps:

[0045] 1. Dissolve phenylhydrazine-4-sulfonic acid (4.0g, 20mmol) and 3-methyl-2-butanone (3.4g, 40mmol) in glacial acetic acid, heat to 120°C in a round bottom flask, nitrogen atmosphere Reflux under protection and react for 14h.

[0046] 2. Ethyl acetate was added to wash twice and the pink solid powder was filtered out and dried in vacuum.

[0047] 3. Dissolve the powder in methanol, add saturated potassium hydroxide solution in isopropanol dropwise, stir in a beaker at room temperature for 2 hours, filter, and dry indole sulfonate.

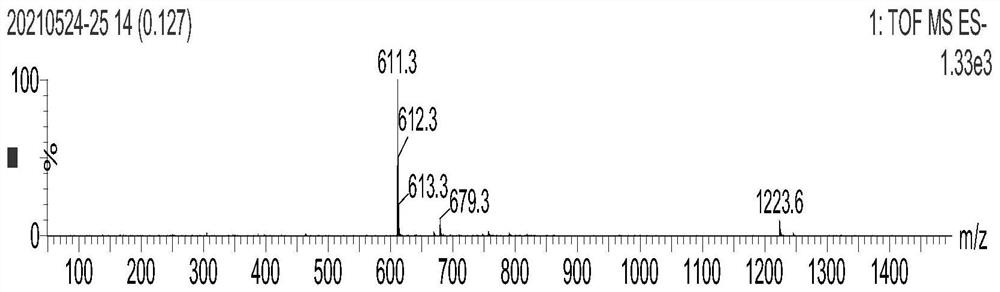

[0048] 4. Dissolve indole sulfonate (4.0g, 14mmol) and bromooctane (4.1g, 21mmol) in acetonitrile, heat to 80°C in a round bottom flask, reflux for 48h under nitrogen atmosphere, filter and dry t...

Embodiment 3

[0052] A water-soluble photochromic compound and a preparation method thereof, using phenylhydrazine-4-sulfonic acid, 3-methyl-2-butanone, potassium hydroxide, 5-nitrosalicylaldehyde and hexadecane bromide as Raw materials, including the following steps:

[0053] 1. Dissolve phenylhydrazine-4-sulfonic acid (4.0g, 20mmol) and 3-methyl-2-butanone (3.4g, 40mmol) in glacial acetic acid, heat to 120°C in a round bottom flask, nitrogen atmosphere Reflux under protection and react for 14h.

[0054] 2. Ethyl acetate was added to wash twice and the pink solid powder was filtered out and dried in vacuum.

[0055] 3. Dissolve the powder in methanol, add saturated potassium hydroxide solution in isopropanol dropwise, stir in a beaker at room temperature for 2 hours, filter, and dry indole sulfonate.

[0056] 4. Indole sulfonate (4.0g, 14mmol) and hexadecane bromide (6.4g, 21mmol) were dissolved in acetonitrile, heated to 80°C in a round bottom flask, refluxed for 48h under nitrogen atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com