A kind of Fischer-Tropsch synthetic naphtha upgrading method for producing high-octane gasoline

A high-octane gasoline and Fischer-Tropsch synthesis technology, applied in the field of coal chemical industry, can solve the problems of difficult removal of reaction heat, easy carbon deposition on catalysts, and difficult continuous production, etc., so as to reduce the lifting and conveying process, improve the quality, and increase the liquid production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

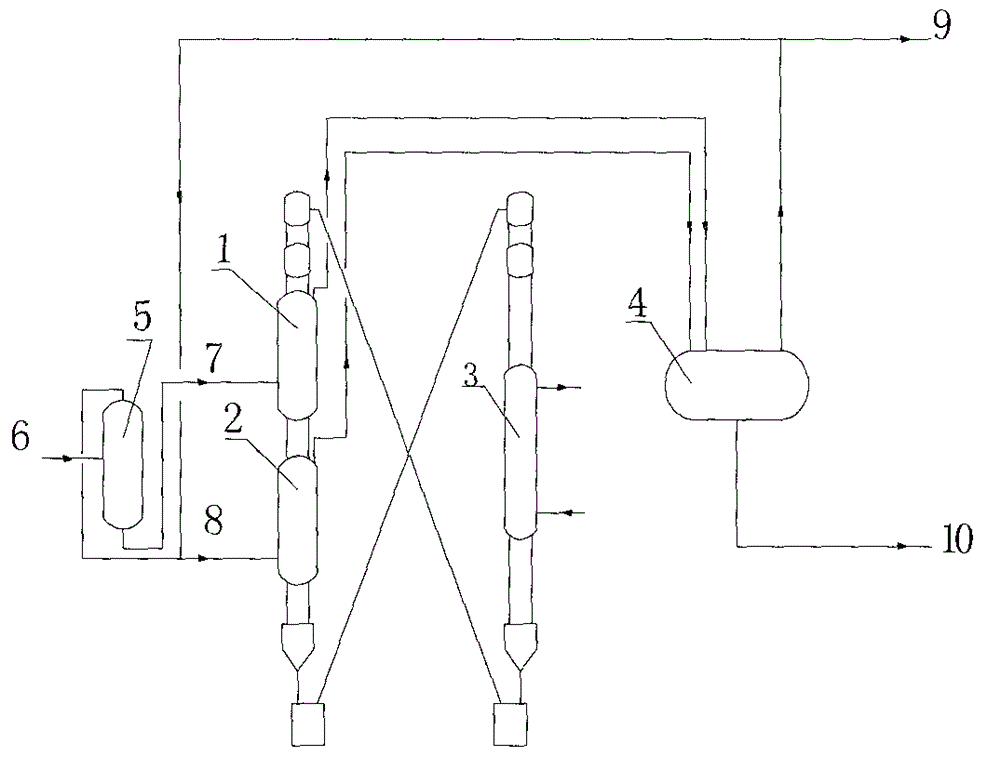

Method used

Image

Examples

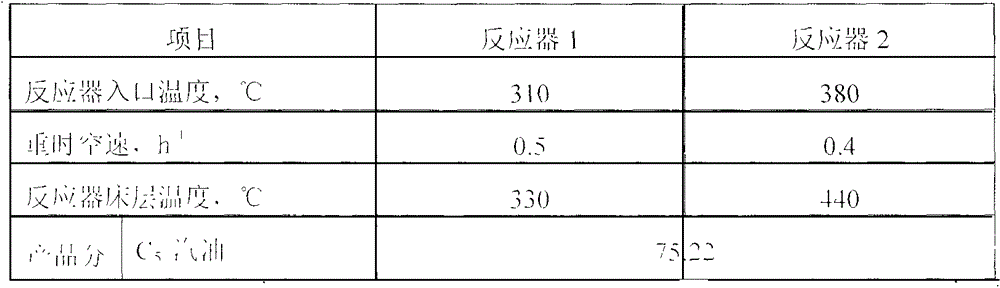

Embodiment 1

[0036] The test raw material is Fischer-Tropsch synthetic naphtha from Lu'an, Shanxi, and the catalyst is ZSM-5 molecular sieve spherical catalyst. The properties of the feedstock fractionation into heavy and light fractions are shown in Tables 1 and 2. The reaction is carried out under non-hydrogen-facing conditions, the inlet temperature of the low-temperature reactor 1 is 310°C, the pressure is 0.25Mpa, and the reaction space velocity is 0.5h -1 ,; The inlet temperature of high temperature reactor 2 is 380℃, the pressure is 0.25Mpa, and the reaction space velocity is 0.4h -1 , The product distribution of the reaction product is shown in Table 3.

[0037] Table 1 Light Distillate Properties

[0038] Distillation range, ℃

<140℃

Alkanes, mass%

25

0

Olefin, mass%

75

Aromatics, mass%

0

[0039] Table 2 Properties of heavy fractions

[0040] Distillation range, ℃

140-200℃

Al...

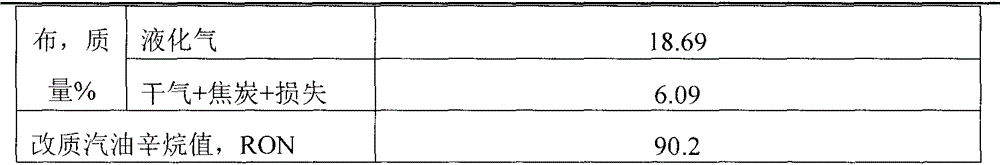

Embodiment 2

[0045] The test raw material is Fischer-Tropsch synthetic naphtha from Lu'an, Shanxi, and the catalyst is ZSM-5 molecular sieve spherical catalyst. The properties of the feedstock fractionation into heavy and light fractions are shown in Tables 1 and 2. The reaction is carried out under non-hydrogen-facing conditions, the inlet temperature of the low-temperature reactor 1 is 350°C, the pressure is 0.25Mpa, and the reaction space velocity is 0.6h -1 ; The inlet temperature of the high temperature reactor 2 is 410°C, the pressure is 0.25Mpa, and the reaction space velocity is 0.5h -1 , The product distribution of the reaction product is shown in Table 4.

[0046] Table 4 Example 2 product distribution

[0047]

Embodiment 3

[0049] The test raw material is Fischer-Tropsch synthetic naphtha from Lu'an, Shanxi, and the catalyst is ZSM-5 molecular sieve spherical catalyst. The properties of the feedstock fractionation into heavy and light fractions are shown in Tables 1 and 2. The reaction is carried out under non-hydrogen-facing conditions. The inlet temperature of the low-temperature reactor 1 is 350°C, the pressure is 0.25Mpa, and the reaction space velocity is 0.7h -1 ; The inlet temperature of the high temperature reactor 2 is 420°C, the pressure is 0.25Mpa, and the reaction space velocity is 0.6h -1 , the product distribution of the reaction product is shown in Table 5.

[0050] Table 5 Example 3 product distribution

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com