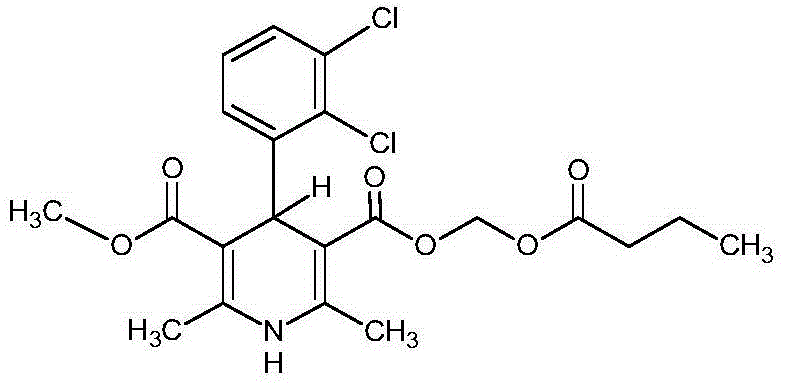

Clevidipine butyrate emulsion and preparation method thereof

A technology of clevidipine butyrate and dipine emulsion, which is applied in the direction of pharmaceutical formula, emulsion delivery, medical preparations containing active ingredients, etc., can solve the problems of poor storage stability, achieve less adverse reactions, ensure stability, and eliminate impurities The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

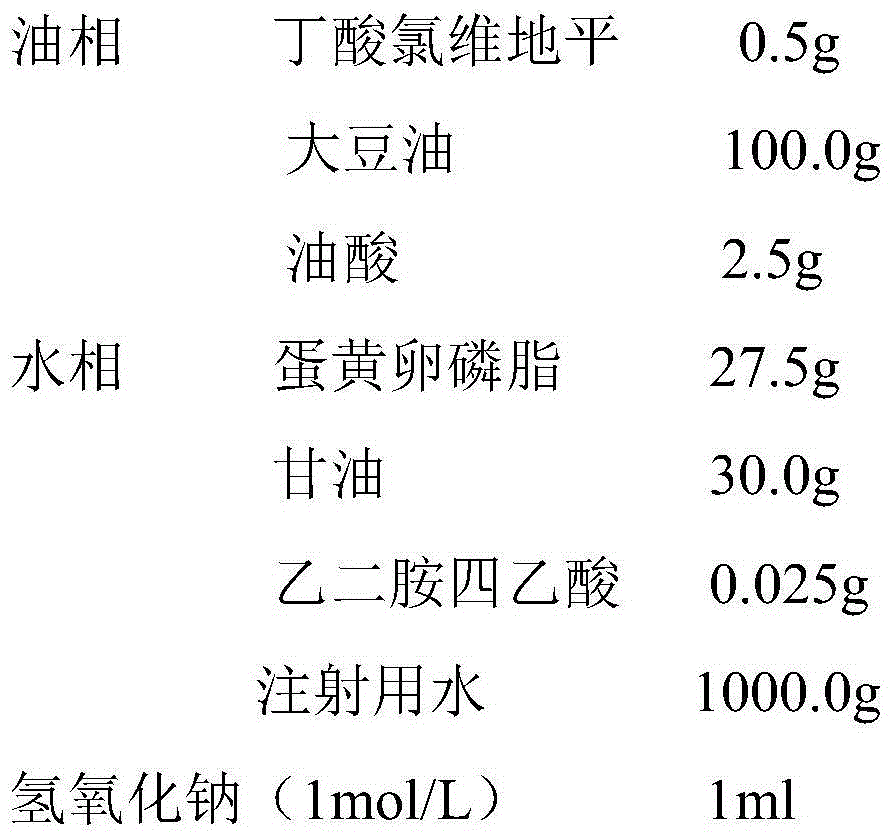

Embodiment 1

[0043] A kind of clevidipine butyrate emulsion, its component and content are as follows:

[0044]

[0045] The preparation method of the clevidipine butyrate emulsion of the present embodiment may further comprise the steps:

[0046] (1) Under a nitrogen atmosphere, mix clevidipine butyrate, soybean oil and oleic acid uniformly at 60°C according to the above formula to obtain an oil phase; mix egg yolk lecithin, glycerin, EDTA and water for injection in Mix evenly at 60°C to obtain the water phase; add the oil phase to the water phase evenly at a rate of 10-20g / min, shear and emulsify at 60°C, the shear speed is 10,000rpm, and the shear time is 30 minutes to obtain the water package oil emulsion;

[0047] (2) Under a nitrogen atmosphere, after the oil-in-water emulsion is cooled to below 25°C, adjust the pH to 7.0 with sodium hydroxide, homogenize under high pressure, the homogenization pressure is 1000bar, and the number of homogenization is 4 times. The temperature is ...

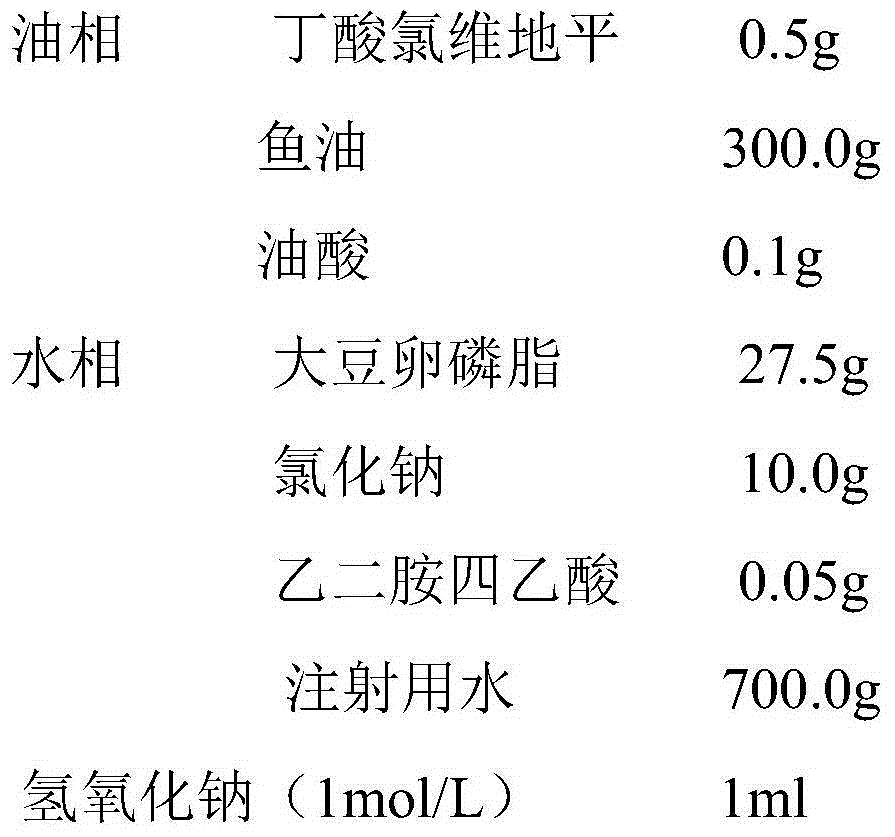

Embodiment 2

[0049] A kind of clevidipine butyrate emulsion, its component and content are as follows:

[0050]

[0051] The preparation method of the clevidipine butyrate emulsion of the present embodiment may further comprise the steps:

[0052] (1) Under a nitrogen atmosphere, mix clevidipine butyrate, fish oil and oleic acid uniformly at 40°C according to the above formula to obtain an oil phase; mix soybean lecithin, sodium chloride, ethylenediaminetetraacetic acid and water for injection Mix evenly at 40°C to obtain the water phase; add the oil phase to the water phase evenly at a speed of 40-60g / min, shear and emulsify at 40°C, the shear speed is 4000rpm, and the shear time is 50 minutes to obtain the water phase oil-in-emulsion;

[0053] (2) Under a nitrogen atmosphere, after the oil-in-water emulsion is cooled to below 25°C, adjust the pH to 9.0 with sodium hydroxide, homogenize under high pressure, the homogenization pressure is 1500bar, and the number of times of homogenizat...

Embodiment 3

[0055] A kind of clevidipine butyrate emulsion, its component and content are as follows:

[0056]

[0057] The preparation method of the clevidipine butyrate emulsion of the present embodiment may further comprise the steps:

[0058] (1) Under a nitrogen atmosphere, mix clevidipine butyrate, castor oil, and trans-oleic acid at 90°C according to the above formula to obtain an oil phase; mix egg yolk lecithin, glycerin, aminotriacetic acid, and water for injection in Mix evenly at 90°C to obtain the water phase; add the oil phase to the water phase evenly at a rate of 90-100g / min, shear and emulsify at 90°C, the shear speed is 12000rpm, and the shear time is 10 minutes to obtain the water package oil emulsion;

[0059] (2) Under a nitrogen atmosphere, after the oil-in-water emulsion is cooled to below 25°C, adjust the pH to 4.0 with hydrochloric acid, homogenize under high pressure, the homogenization pressure is 500bar, and the homogenization times are 6 times, and the hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com