A kind of disulfiram enteric-coated tablet and preparation method thereof

A technology of disulfiram and enteric-coated tablets, which is applied in the directions of pharmaceutical formulation, drug delivery, drug combination, etc., can solve the problems of unreported disulfiram preparation products, studies on disulfiram-free enteric-coated tablets, etc., and achieve biological High utilization, easy to scale up industrial production, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Table 1 Raw and auxiliary materials used in Example 1 and their consumption

[0053]

[0054] Preparation Process

[0055] 1) Preparation of disulfiram solid dispersion:

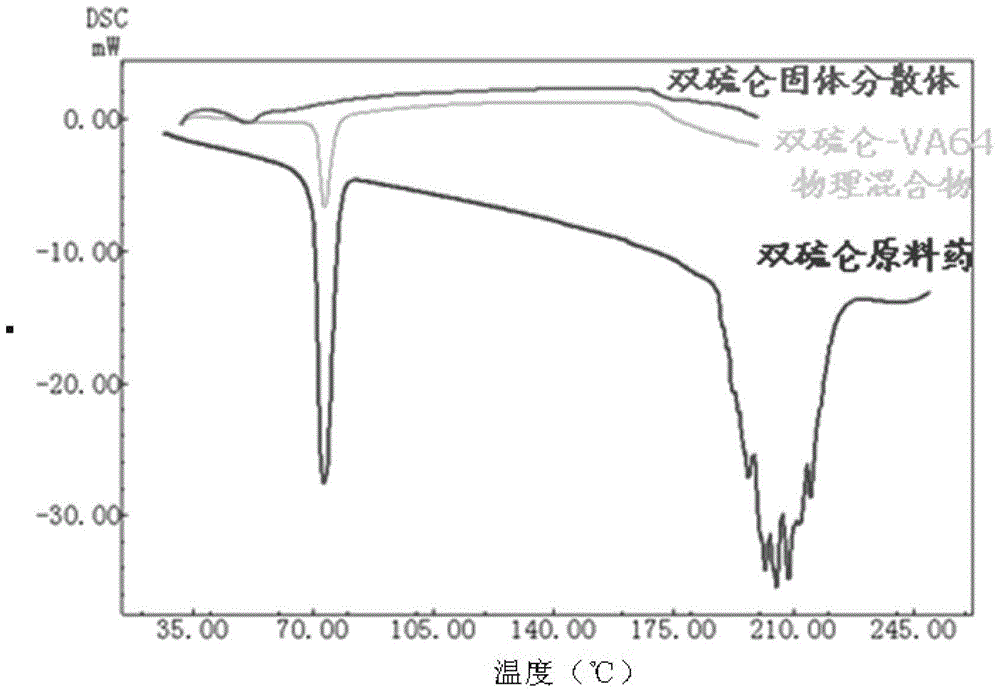

[0056] Take the prescribed amount of disulfiram API and the prescribed amount of copovidone PVP / VA64 and mix them evenly, then add them to the feeding hopper of the hot-melt extruder; set the host frequency to 3Hz, the feeding frequency to 2.5Hz, and the temperature to 130°C; After smoothing, turn on the oil pump and turn on the main machine and feed at the same time to prepare a solid dispersion; collect the extruded product into a stainless steel pan, cool at room temperature for 24 hours, crush, and sieve to obtain powdered disulfiram with a particle size between 60 and 80 Solid dispersion. The DSC figure of disulfiram solid dispersion sees attached figure 1 .

[0057] 2) Preparation of tablet core

[0058] After uniformly mixing the prepared disulfiram solid dispersion with the prescribed ...

Embodiment 2

[0062] Table 2 Raw materials used in Example 2 and their consumption

[0063]

[0064] The preparation process is the same as in Example 1.

Embodiment 3

[0066] Table 3 The raw materials used in Example 3 and their consumption

[0067]

[0068] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com