Opopanax extract, preparation method and application thereof

A technology of Acacia and its extracts, which is applied in application, animal feed, food preparation, etc., can solve the problems of undisclosed tyrosinase inhibition and undisclosed whitening of Acacia plants, and achieves controllable product quality, Inhibition of melanin production, the method is safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

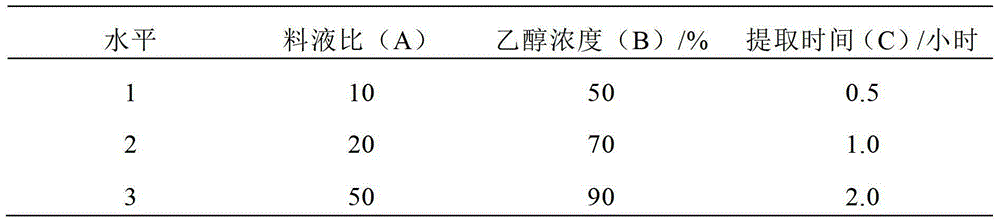

[0029] The preferred of embodiment 1 acacia extraction condition

[0030] Fresh Acacia 10g, using L 9 (3 4) orthogonal test (commonly used mathematical methods and computer programs for drug research [P], Guizhou Science and Technology Press, 1997) to optimize the extraction process, with the ratio of solid to liquid (A), ethanol concentration (B), and extraction time (C) as Trial factors, and blank columns (D). Orthogonal design experiments were carried out with the extraction rate as the index to optimize the extraction process conditions. The factor level design is shown in Table 1. Considering the production cost, the extraction time is generally not more than 2 hours. The results are shown in Table 2.

[0031] Table 1 Orthogonal test factor levels

[0032]

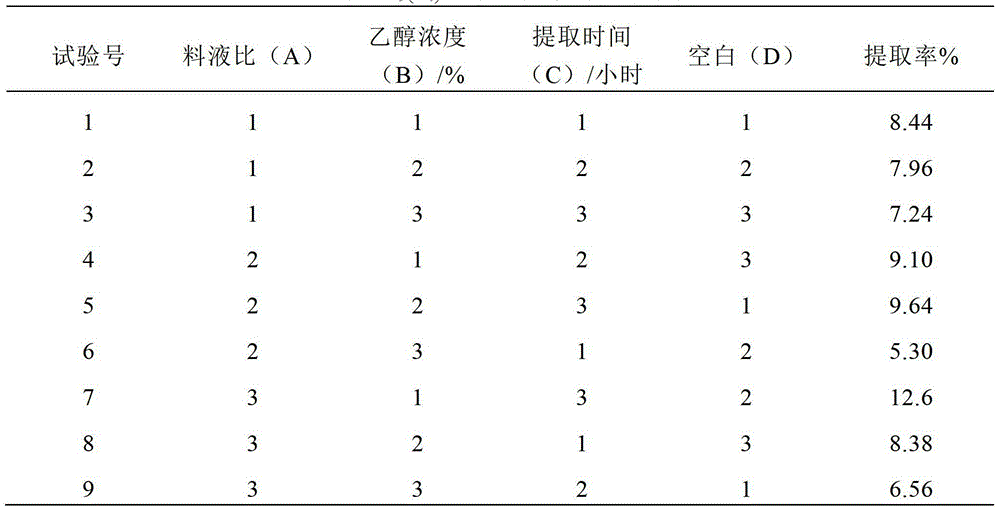

[0033] Form 2L 9 (3 4 ) Orthogonal test design and result table

[0034]

[0035] Table 3 Orthogonal test visual analysis table

[0036]

[0037] Table 4 Orthogonal test analysis of variance table

...

Embodiment 2

[0041] The preparation of embodiment 2 Acacia flower bud extract

[0042] After washing 100g of Acacia flower buds, mix them with 2L of 70v / v% ethanol solution, conduct ultrasonic extraction at room temperature for 1 hour, separate the crude extract, evaporate the ethanol solution under reduced pressure, and obtain 6g of Acacia flower bud crude extract.

[0043] Take 1 g of the crude extract of Acacia flower buds, dissolve it in deionized water, load it on the AB-8 resin-filled column, and wash it with deionized water, 20v / v% ethanol, 40v / v% ethanol, 60v / v% ethanol and Gradient elution with 80v / v% ethanol, collect the eluents separately, distill ethanol and water under reduced pressure, and obtain water-washed parts, 20v / v% ethanol parts, 40v / v% ethanol parts, 60v / v% ethanol parts and 80v Acacia flower bud extract from the / v% ethanol fraction, frozen at -20°C.

Embodiment 3

[0044] The preparation of embodiment 3 acacia bark extract

[0045] After washing 50g of Acacia bark, mix it with 1L of 70v / v% ethanol solution, extract it by circulating countercurrent extraction for 2 hours, separate the crude extract, and distill deionized water under reduced pressure to obtain the crude extract of Acacia bark 5g.

[0046] Take 5g of the crude extract of Acacia bark, dissolve it in deionized water, load the sample onto the X-5 resin-filled column, and wash it with deionized water, 20v / v% ethanol, 40v / v% ethanol, and 60v / v% ethanol in sequence and 80v / v% ethanol gradient elution, collect the eluent respectively, evaporate ethanol and water under reduced pressure, and obtain the water washing part, 20v / v% ethanol part, 40v / v% ethanol part, 60v / v% ethanol part and Acacia bark extract in 80v / v% ethanol fraction, frozen at -20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com