Device and method for producing electrical energy and biogas fertilizer by using livestock and poultry manure and crop stalks

A technology of crop stalks and livestock and poultry manure, which is applied in the direction of fertilization equipment, preparation and application of organic fertilizers, etc., can solve the problems of secondary pollution of reaction waste, general power generation performance, cumbersome operation, etc., and achieve low production cost and wide application Application potential, good effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

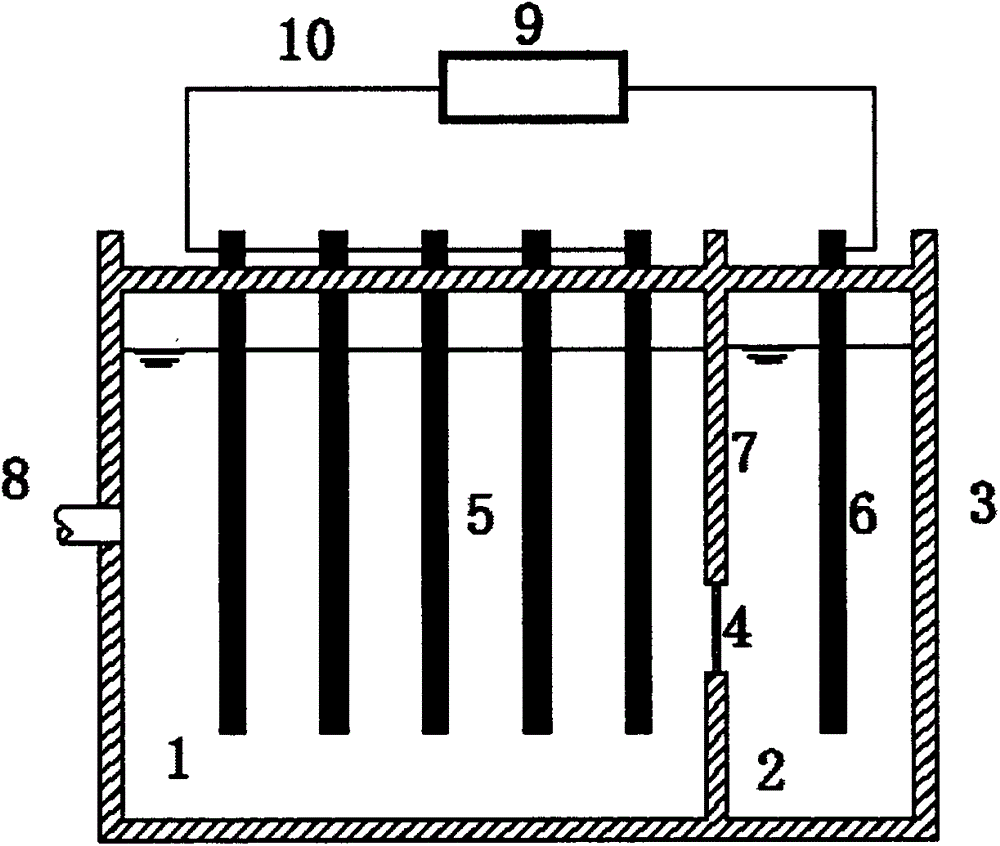

[0025] A device for obtaining electric energy and biogas manure by using livestock and poultry manure and crop stalks, including a tank body 3, which is divided into an anode chamber 1 and a cathode chamber 2 through a partition 7, and a cathode material 6 is arranged in the cathode chamber 2, and the An anode material 5 is arranged in the anode chamber 1, and the cathode material 6 and the anode material 5 are connected to an external circuit load 9 through a wire 10, and a polyethylene heterogeneous cation exchange membrane 4 is arranged on the separator 7 near the bottom of the tank; The acclimated electrogenic microbial flora, treated livestock and poultry manure and crop straw are evenly stirred and then added to the anode chamber 1 as the anode chamber liquid in an intermittent or continuous manner, and water is added to the cathode chamber 2 as the cathode chamber liquid; at a temperature of 25 Under the condition of ~37°C, after constant temperature cultivation for 12-3...

Embodiment 2

[0039] Crush the crop straws to <1mm, and soak them in appropriate distilled water for 17 hours; cut the polyethylene heterogeneous cation exchange membrane into 1.5cm×1cm, soak it in distilled water for 24 hours, and fix it between the anode chamber and the cathode chamber;

[0040] Prepare a double-chamber reaction device of 20cm * 15cm * 10cm; the size of the anode chamber and the cathode chamber are respectively 10.3cm * 3.5cm * 10cm and 3.2cm * 3.5cm * 10cm; used straw is corn stalk, and its moisture content is 6.95%, The carbon, nitrogen, phosphorus and potassium contents are 50.82%, 0.23%, 0.15%, and 1.96% respectively; the livestock and poultry manure used is cow dung with a moisture content of 82.25%, and the carbon, nitrogen, phosphorus, and potassium contents are 9.01%, 9.01%, and 1.96%, respectively. 0.65%, 0.75%, 1.00%; add 20.0g and 1.0g of the above cow dung and corn stalks to the anode chamber, add 20ml of biogas slurry to inoculate microorganisms, add water and...

Embodiment 3

[0045] Crush the crop straws to <1mm, and soak them in appropriate distilled water for 15 hours; cut the polyethylene heterogeneous cation exchange membrane into 5cm×9cm, soak it in distilled water for 24 hours, and then fix it between the anode chamber and the cathode chamber;

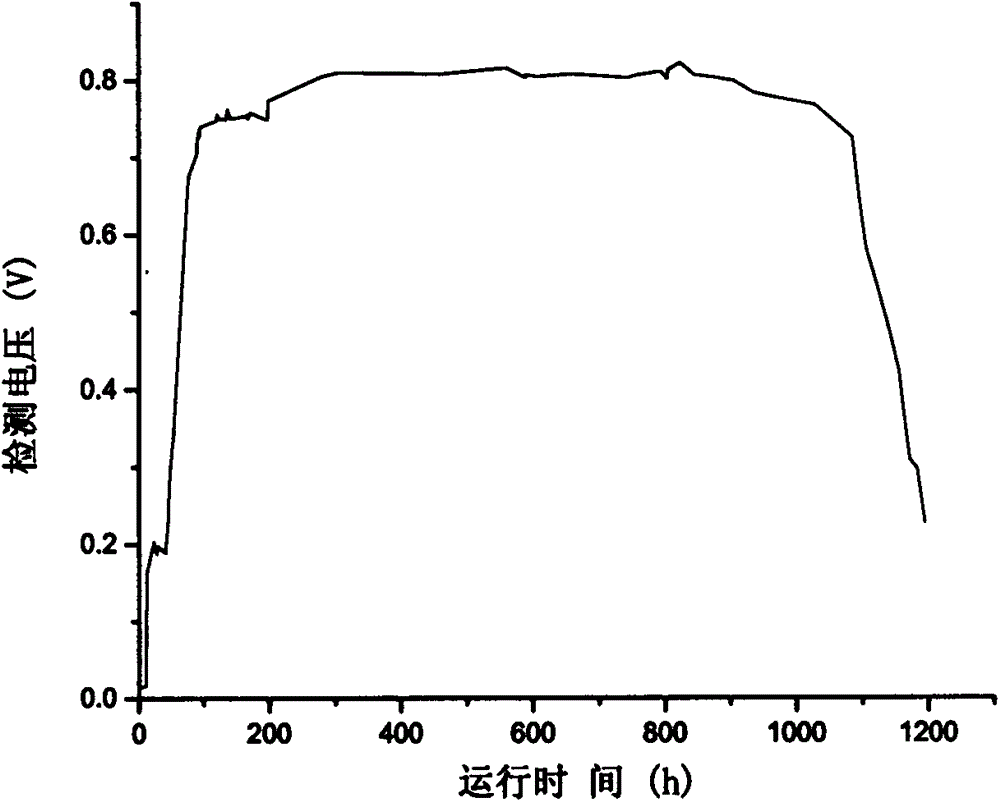

[0046] A double-chamber reaction device of 30cm×20cm×20cm was prepared; the size of the anode chamber and the cathode chamber were 20cm×20cm×20cm and 10cm×20cm×20cm respectively; the stalk used was corn stalk, and its moisture content was 7.0%. The phosphorus and potassium contents are 46.75%, 0.48%, 0.85%, and 0.37% respectively; the livestock and poultry manure used is cow dung with a water content of 85.6%, and the carbon, nitrogen, phosphorus, and potassium contents are 9.35%, 0.59%, and 0.83% respectively. %, 0.96%; add 240g of cow dung and 25g of corn stalks to the anode chamber, add 180ml of biogas slurry to inoculate microorganisms, add water and stir evenly to adjust the solid content to 5%; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com