Glass-ceramic target material and preparation method thereof

A glass-ceramic and glass-ceramic powder technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of unsuitable glass-ceramic targets, reduce the risk of target cracking and failure, The effect of good electrical and thermal conductivity and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

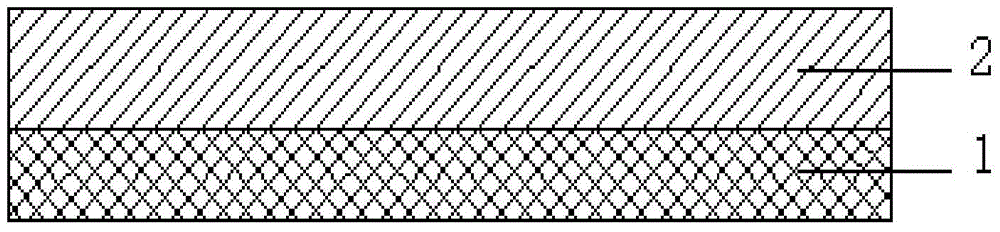

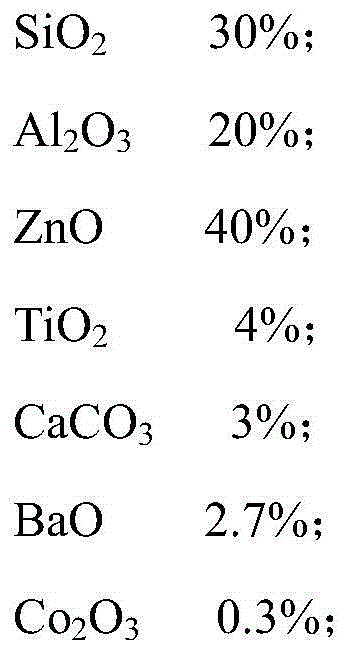

[0035] a kind of like figure 1 , figure 2 The glass-ceramic target material of the present invention shown in the present invention includes an alloy back plate 1 and a glass-ceramic body 2 from bottom to top, and is a double-layer structure, wherein the alloy back plate 1 is Inconel600 high-temperature-resistant nickel-based alloy with a thickness of 1.5mm; the glass ceramic The main body 2 is prepared by transferring ceramic powder on the aforementioned alloy backplane through a screen printing process and then sintering. The glass ceramic main body 2 is ZnO-Al 2 o 3 -SiO 2 Glass ceramics, the glass ceramic body is mainly composed of ZnO, Al 2 o 3 , SiO 2 , BaO, CaCO 3 、TiO 2 、Co 2 o 3It is prepared by mixing and melting at a mass ratio of 40:20:30:2.7:3:4:0.3, and the thickness of the glass ceramic body is 0.5mm. The alloy back plate 1 is connected with the glass ceramic body 2 through chemical bonding. The glass-ceramic target in this embodiment is a circular t...

Embodiment 2

[0046] a kind of like figure 1 The glass-ceramic target material of the present invention as shown includes an alloy back plate 1 and a glass-ceramic body 2 from bottom to top, and has a double-layer structure, wherein the alloy back plate 1 is Inconel715 high-temperature-resistant nickel-based alloy with a thickness of 2.0mm; the glass ceramic The main body 2 is prepared by transferring ceramic powder on the aforementioned alloy backplane 1 through a screen printing process and then sintering. The glass ceramic main body 2 is ZnO-Al 2 o 3 -SiO 2 Glass ceramics, the glass ceramic body is mainly composed of ZnO, Al 2 o 3 , SiO 2 , BaO, CaCO 3 、TiO 2 、Co 2 o 3 It is prepared by mixing and melting at a mass ratio of 38:25:27:2.6:1:6:0.4, and the thickness of the glass ceramic body is 1.0 mm. The alloy back plate 1 is connected with the glass ceramic body 2 through chemical bonding. The glass-ceramic target in this embodiment is a square target with a side length of 80 m...

Embodiment 3

[0057] a kind of like figure 1 The glass-ceramic target material of the present invention shown in the present invention includes an alloy back plate 1 and a glass-ceramic body 2 from bottom to top, and has a double-layer structure, wherein the alloy back plate 1 is a GH3030 high-temperature-resistant nickel-based alloy with a thickness of 2.5 mm; the glass ceramic The main body 2 is prepared by transferring ceramic powder on the aforementioned alloy backplane 1 through a screen printing process and then sintering. The glass ceramic main body 2 is ZnO-Al 2 o 3 -SiO 2 Glass ceramics, the glass ceramic body is mainly composed of ZnO, Al 2 o 3 , SiO 2 , BaO, CaCO 3 、TiO 2 、Co 2 o 3 It is prepared by mixing and melting at a mass ratio of 46:15:31:1.8:3:3:0.2, and the thickness of the glass ceramic body is 1.5 mm. The alloy back plate 1 is connected with the glass ceramic body 2 through chemical bonding. The glass-ceramic target in this embodiment is a circular target wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com