Finasteride capsule and preparation method thereof

A technology of finasteride and capsules, applied in the field of finasteride capsules and preparation thereof, can solve problems such as changing and affecting the effect of drug treatment, and achieves reduction of operation time, reduction of the risk of damage to the main drug, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Direct powder filling process

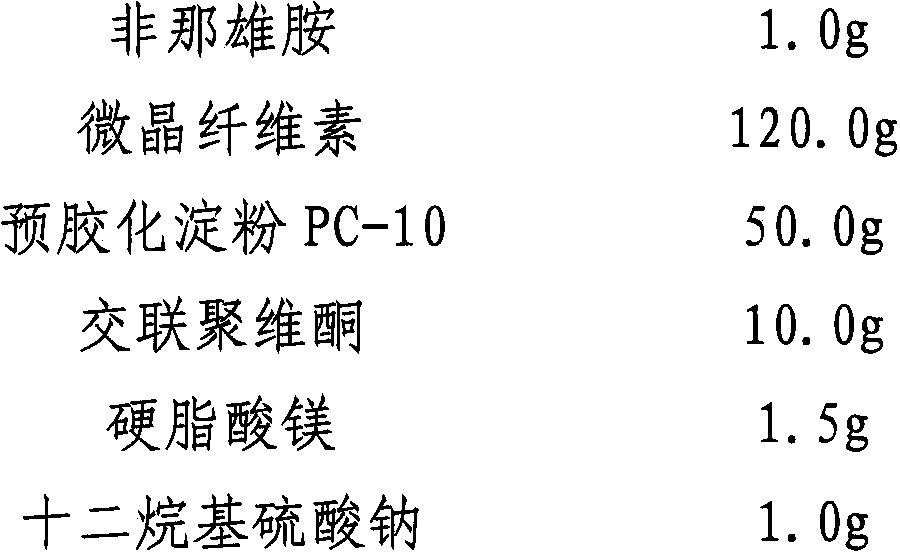

[0026] prescription:

[0027]

[0028] Process:

[0029] Pass the microcrystalline cellulose, pregelatinized starch PC-10, crospovidone, magnesium stearate, and sodium lauryl sulfate through an 80-mesh sieve for use; pass the raw materials through a 100-mesh sieve for use; weigh according to the above prescription Take the raw and auxiliary materials, mix the weighed finasteride with the same amount of microcrystalline cellulose by the equal volume addition method, and then sieve and mix with the rest of the auxiliary materials; place the mixed powder in a multi-directional motion mixer for total mixing , Set the mixing speed to 1100r / min, and the mixing time to 30min; detect the properties and content of the intermediates, and fill the capsules after meeting the internal control quality standards. Example 2: Direct powder filling process

Embodiment 2

[0029] Pass the microcrystalline cellulose, pregelatinized starch PC-10, crospovidone, magnesium stearate, and sodium lauryl sulfate through an 80-mesh sieve for use; pass the raw materials through a 100-mesh sieve for use; weigh according to the above prescription Take the raw and auxiliary materials, mix the weighed finasteride with the same amount of microcrystalline cellulose by the equal volume addition method, and then sieve and mix with the rest of the auxiliary materials; place the mixed powder in a multi-directional motion mixer for total mixing , Set the mixing speed to 1100r / min, and the mixing time to 30min; detect the properties and content of the intermediates, and fill the capsules after meeting the internal control quality standards. Example 2: Direct powder filling process

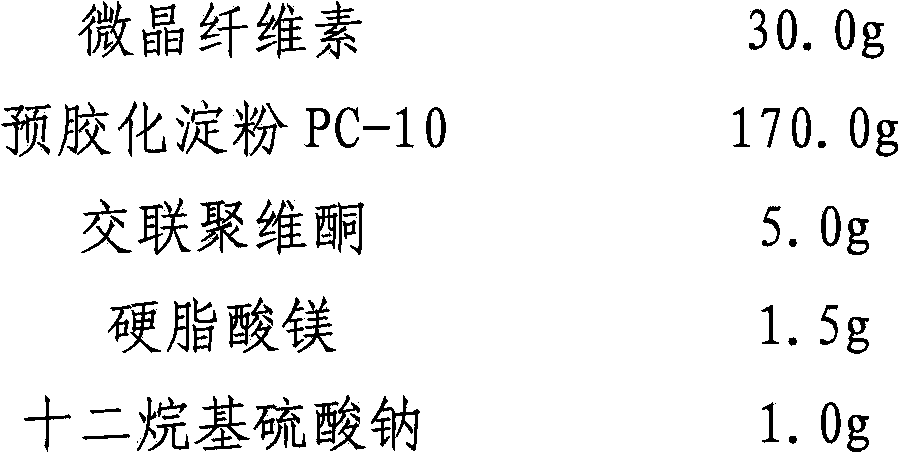

[0030] prescription:

[0031]

[0032]

[0033] Process:

[0034] Pass the microcrystalline cellulose, pregelatinized starch PC-10, crospovidone, magnesium stearate, and sodium lauryl sulfate t...

Embodiment 3

[0034] Pass the microcrystalline cellulose, pregelatinized starch PC-10, crospovidone, magnesium stearate, and sodium lauryl sulfate through an 80-mesh sieve for use; pass the raw materials through a 100-mesh sieve for use; weigh according to the above prescription Take the raw and auxiliary materials, mix the weighed finasteride with the same amount of microcrystalline cellulose by the equal volume addition method, and then sieve and mix with the rest of the auxiliary materials; place the mixed powder in a multi-directional motion mixer for total mixing , Set the mixing speed to 1000r / min, and the mixing time to 15min; detect the properties and content of the intermediate, and fill the capsule after meeting the internal control quality standard. Example 3: Direct powder filling process

[0035] prescription:

[0036]

[0037] Process:

[0038] Pass lactose, pregelatinized starch PC-10, microcrystalline cellulose, sodium starch glycolate, crospovidone, talc, and sodium lauryl sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com