Activated carbon loaded titanium dioxide composite photocatalyst and preparation method thereof

A technology of titanium dioxide and activated carbon, which is applied in the field of activated carbon-supported titanium dioxide composite photocatalyst and its preparation, can solve the problems of poor reusability, low reaction rate, easy powder agglomeration, etc., achieve good sterilization, simple preparation method, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Pretreatment of activated carbon carrier

[0026] First, add a certain amount of activated carbon carrier into distilled water and stir evenly for 5 minutes, then place it in an ultrasonic cleaner for 30 minutes; then put the activated carbon carrier into a HCl solution with a concentration of 0.1mol / L, mix it thoroughly for 30 minutes, and let it stand for 24 hours , filtered and washed with distilled water until neutral. The activated carbon was baked in an oven at 80°C for 2 hours, cooled and then used for later use. The main purpose of this step is to clean the activated carbon carrier.

[0027] (2) TiO loaded on activated carbon 2 Preparation of photocatalyst precursors

[0028] Dissolve 5 mL of n-tetrabutyl titanate in 34 mL of absolute ethanol, add 2 mL of glacial acetic acid after stirring, add 0.45 g of activated carbon in step (1), and soak for 4 hours; slowly add 2 mL of deionized water to the mixture under vigorous stirring , adjust the pH value to 2...

Embodiment 2

[0035] (1) The pretreatment process of activated carbon carrier is the same as embodiment 1.

[0036] (2) TiO loaded on activated carbon 2 Preparation of photocatalyst precursors

[0037] Dissolve 3 mL of n-tetrabutyl titanate in 34 mL of absolute ethanol, add 2 mL of glacial acetic acid after stirring, add 0.27 g of activated carbon in step (1), and soak for 5 hours; slowly add 2 mL of deionized water to the mixture under vigorous stirring , adjust the pH value to 2 with 1mol / L nitric acid, and stir for 10 hours to obtain activated carbon-supported TiO 2 Precursors of photocatalysts;

[0038] (3) The preparation process of activated carbon-supported titanium dioxide composite photocatalyst is the same as that in Example 1.

[0039] Test Results:

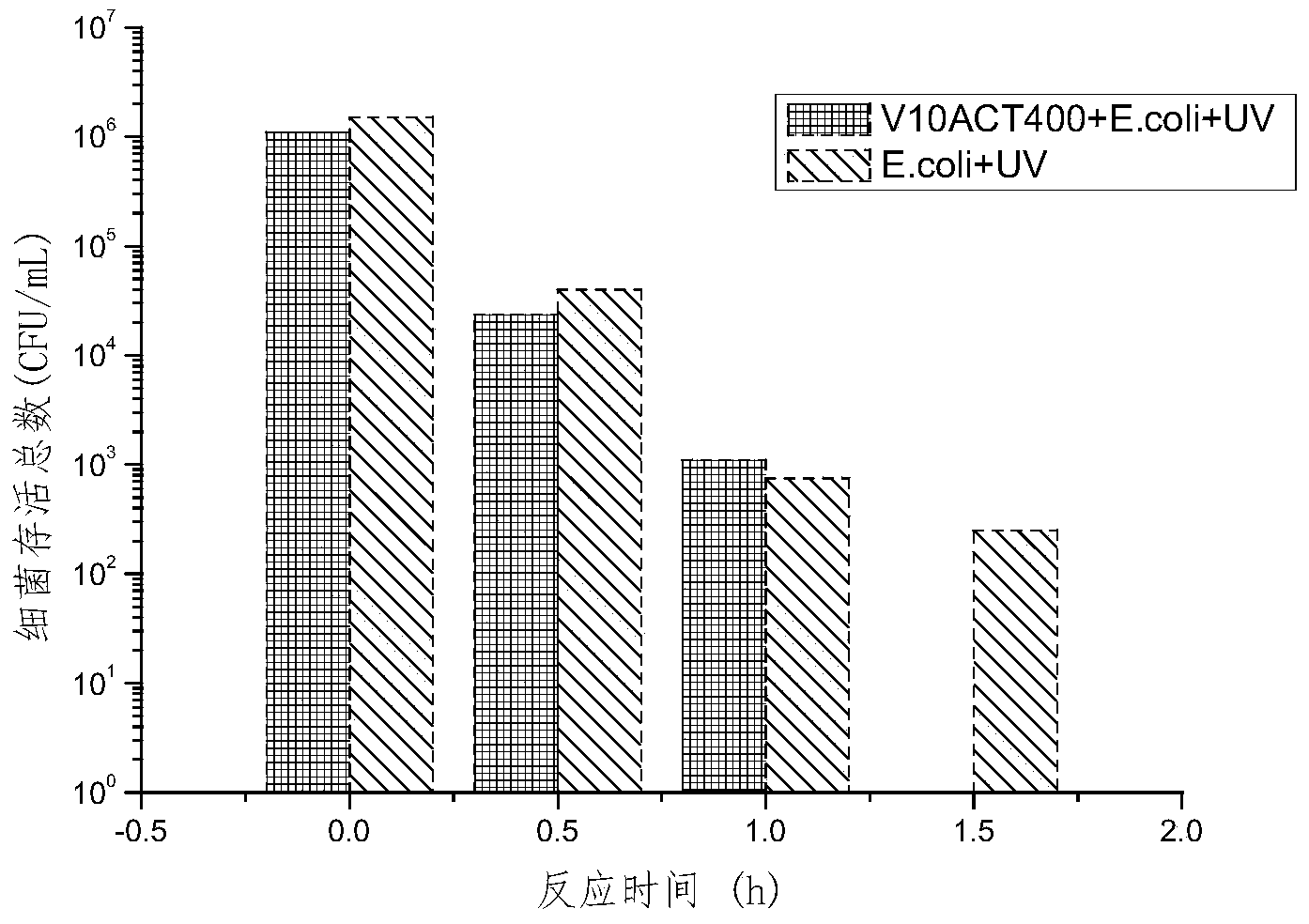

[0040] The detection process is the same as in Example 1, adding 1g / L of granular activated carbon loaded TiO in the water sample to be tested 2 After the photocatalyst, the inactivation rate of Escherichia coli was greatly aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com