Al<3+>-doped Bi2Fe4O9 multiferroic ceramic material and preparation method thereof

A technology of multiferroic ceramics and multiferroic ceramics, which is applied in the field of multiferroic ceramic materials, can solve the problems that there are no reports on multiferroic ceramic materials, and achieve the effects of short sintering time, simple preparation process and low phase formation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

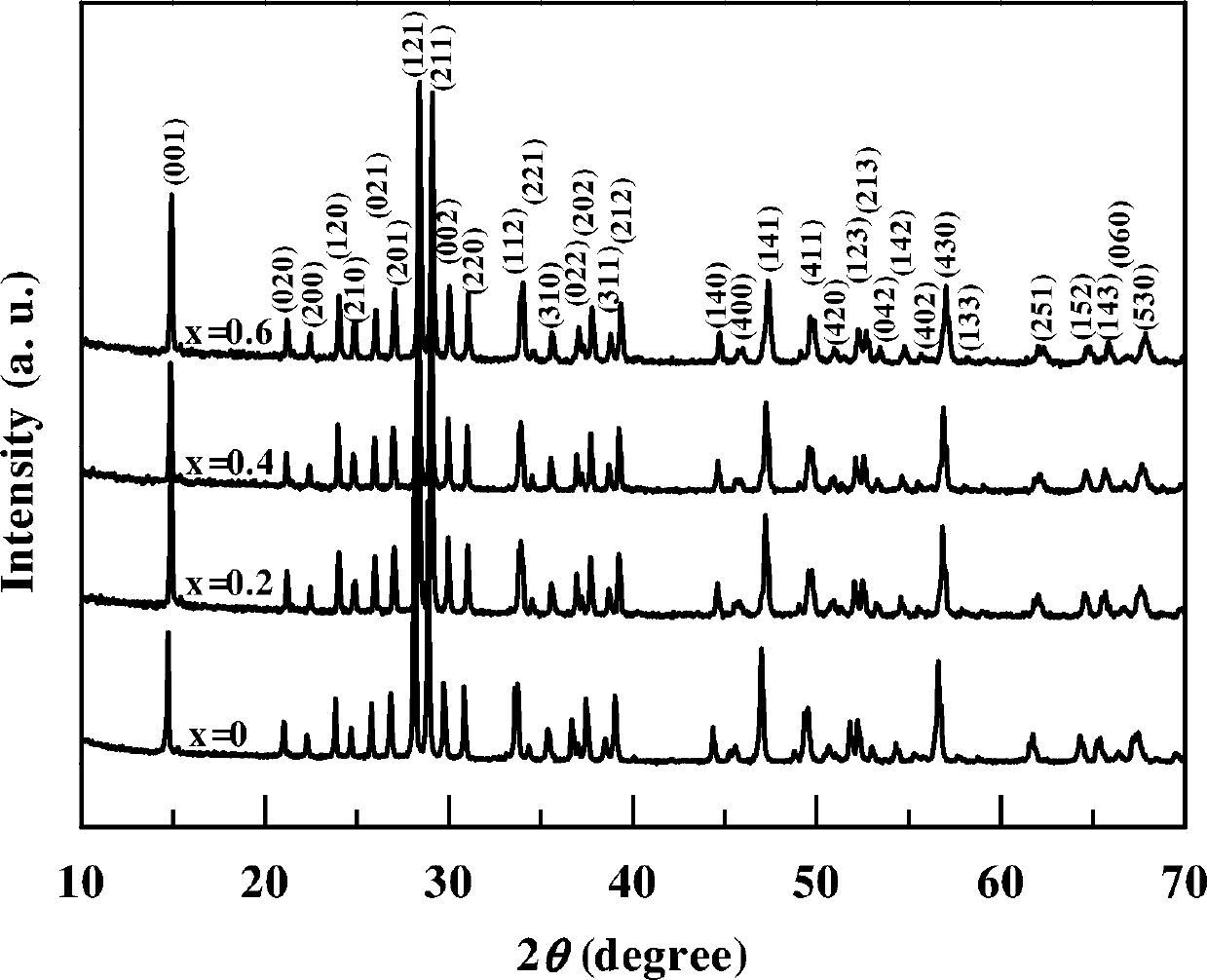

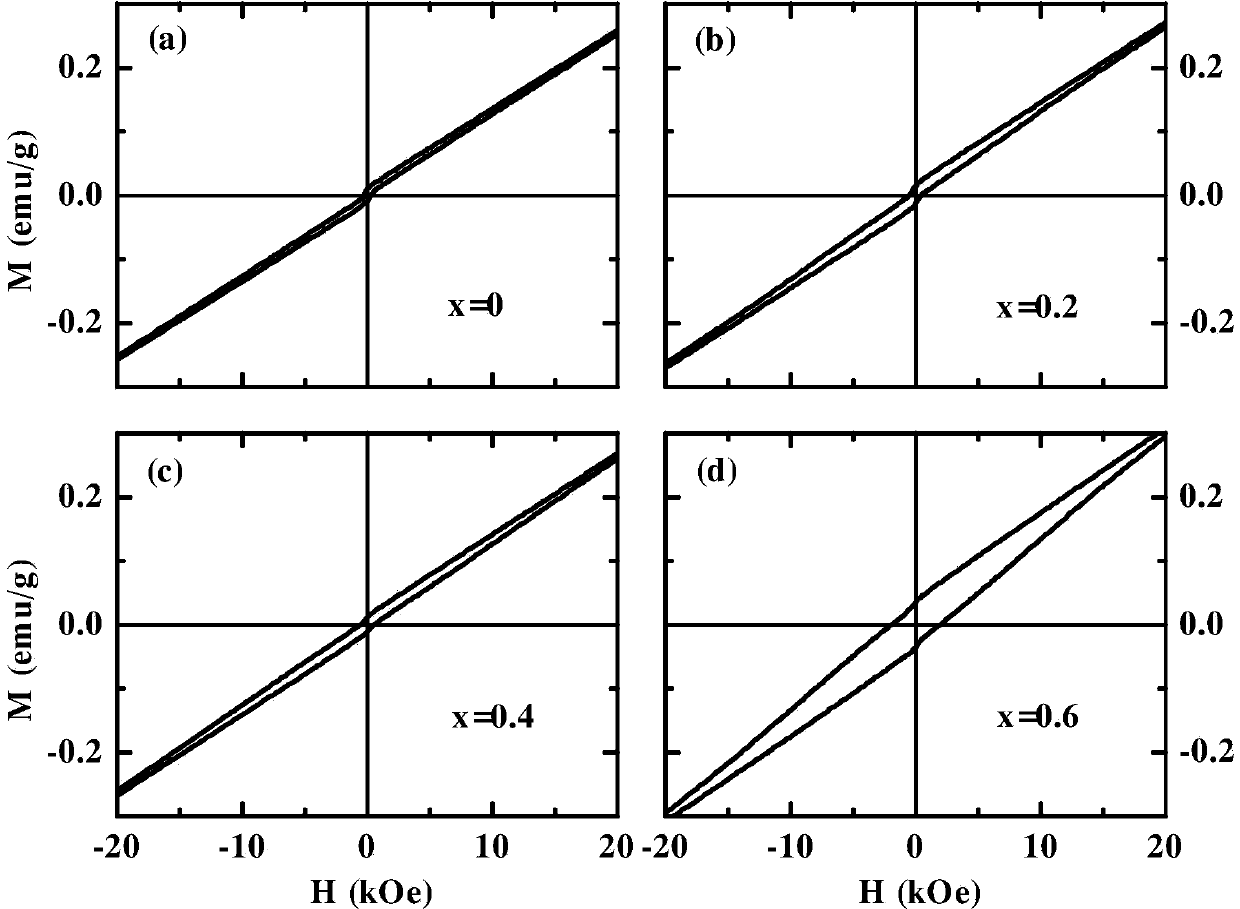

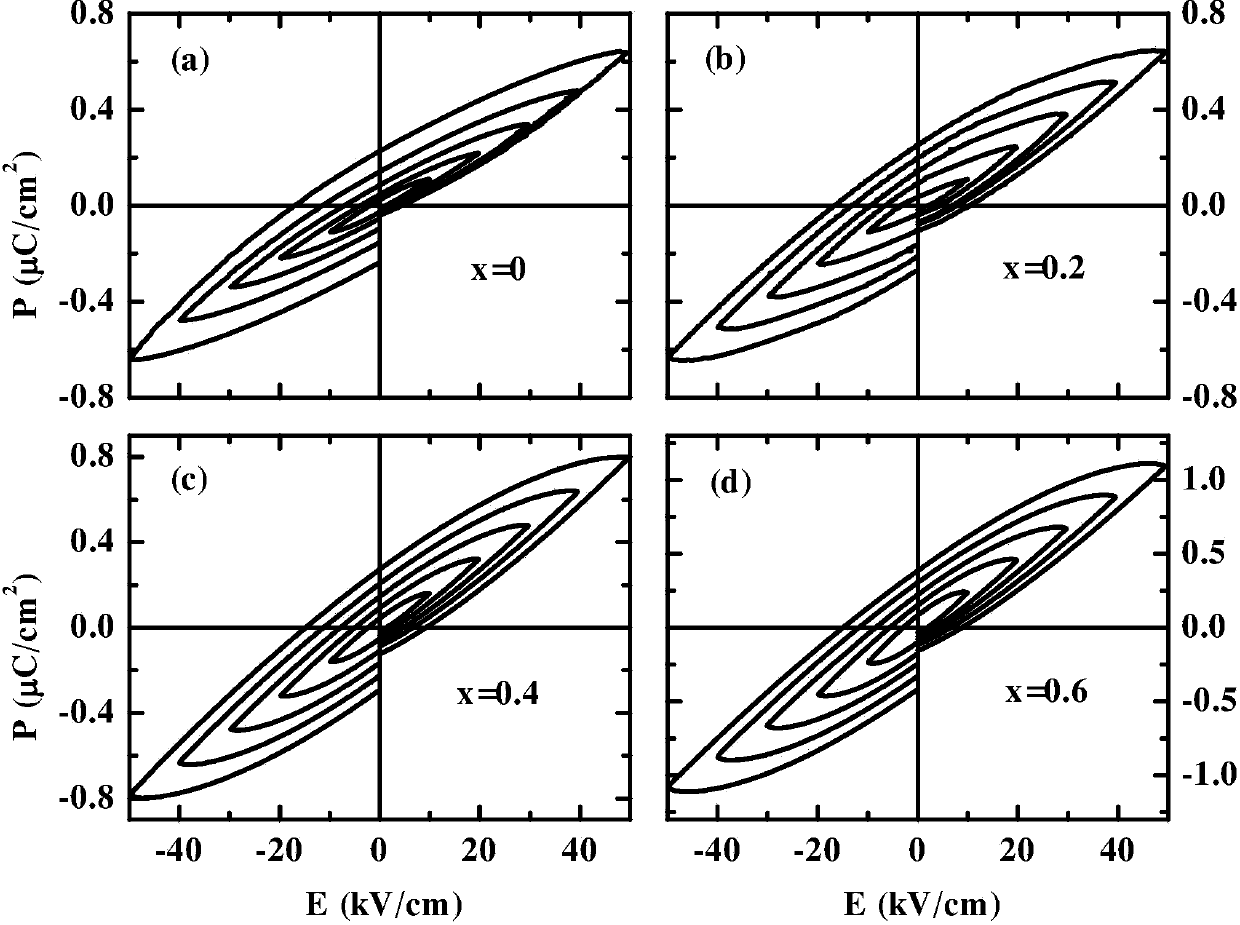

[0018] Bi was prepared by the citric acid-nitrate sol-gel method 2 Fe 4-x Al x o 9 (x=0) multiferroic ceramics. In the first step, weigh 0.06mol of citric acid and put it into a 100mL beaker, add 20mL of distilled water, dissolve under magnetic stirring to form a transparent solution, then weigh 0.02mol of bismuth nitrate, 0.04mol of ferric nitrate, and add the above citric acid solution, and magnetically stirred to form a homogeneous solution, wherein the molar ratio of citric acid to the above two metal cations is 1:1. In the second step, adjust the pH value to 7 with ammonia water under constant stirring, and age the mixed solution for 12 hours; then evaporate the solution to dryness in a water bath at 80°C to remove water, and dry it in an oven at 150°C until a black dry gel. The third step is to fully grind the collected xerogel, heat-treat it in the air at 500°C for 6 hours, remove organic matter, and obtain the precursor powder; then grind the precursor powder, pre...

Embodiment 2

[0021] Bi was prepared by the citric acid-nitrate sol-gel method 2 Fe 4-x Al x o 9 (x=0.2) Multiferroic ceramics. The first step, weigh 0.072mol of citric acid and put it into a 100mL beaker, add 20mL of distilled water, dissolve under magnetic stirring to form a transparent solution, then weigh 0.02mol of bismuth nitrate, 0.038mol of iron nitrate, 0.002mol of aluminum nitrate, and added into the above citric acid solution, and magnetically stirred to form a uniform solution, wherein the molar ratio of citric acid to the above three metal cations is 1.2:1. In the second step, adjust the pH value to 7 with ammonia water under constant stirring, and age the mixed solution for 18 hours; then evaporate the solution to dryness in a water bath at 90°C to remove water, and dry it in an oven at 160°C until a black dry gel. The third step is to fully grind the collected xerogel, heat-treat it in the air at 550°C for 5 hours, remove organic matter, and obtain the precursor powder; ...

Embodiment 3

[0024] Bi was prepared by the citric acid-nitrate sol-gel method 2 Fe 4-x Al x o 9 (x=0.4) Multiferroic ceramics. In the first step, weigh 0.078mol of citric acid and put it into a 100mL beaker, add 20mL of distilled water, and dissolve under magnetic stirring to form a transparent solution. and added into the above citric acid solution, and magnetically stirred to form a uniform solution, wherein the molar ratio of citric acid to the above three metal cations was 1.3:1. In the second step, adjust the pH value to 8 with ammonia water under constant stirring, and age the mixed solution for 20 hours; then evaporate the solution to dryness in a water bath at 100°C to remove water, and dry it in an oven at 170°C until a black dry gel. The third step is to fully grind the collected xerogel, heat-treat it in the air at 600°C for 4 hours, remove organic matter, and obtain the precursor powder; then grind the precursor powder, press the tablet and sinter, the sintering temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com