X8R type MLCC medium material with bias voltage characteristic and stable temperature for medium temperature sintering

A dielectric material and stable technology, applied in the field of temperature-stabilized X8R type MLCC dielectric materials, can solve the problems of dielectric constant drop, etc., and achieve good formability, good development and industrialization prospects, good temperature stability and bias characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

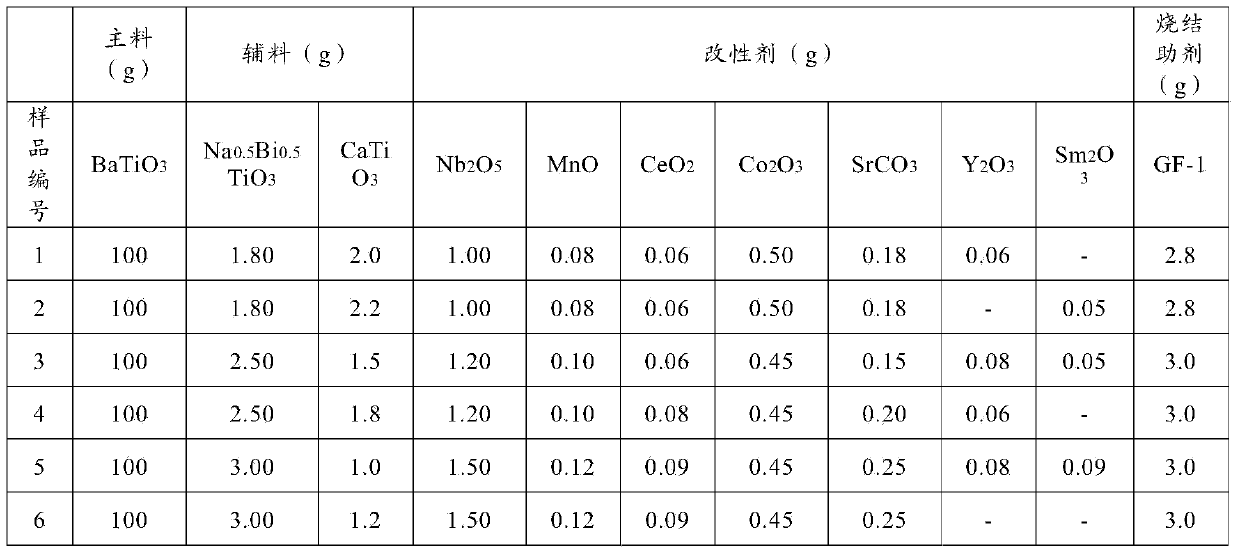

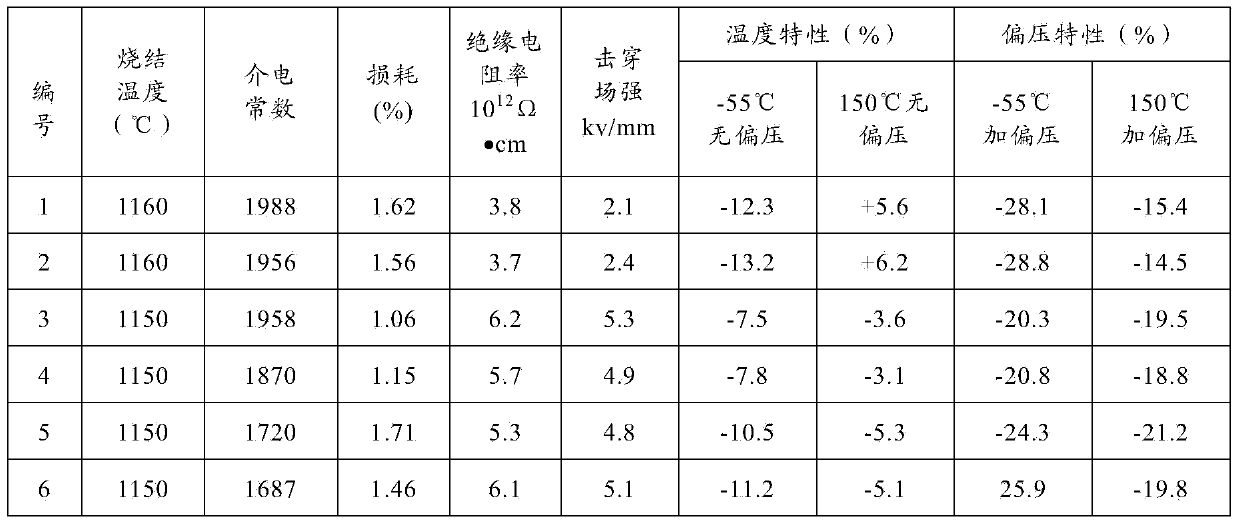

Examples

Embodiment 1

[0045] A temperature-stable X8R type MLCC dielectric material with bias characteristics for medium-temperature sintering is composed of main materials, auxiliary materials, modifiers and sintering aids. Among them, the main material BaTiO 3 Granularity D 50 =0.65 μm, purity ≥99.8%.

[0046] Weigh Bi according to the molar ratio of 1.01:1.01:4 2 o 3 、Na 2 CO 3 and TiO 2 , mixed ball milling with absolute ethanol as the medium for 10 hours, dried at 80°C for 6 hours, ground and passed through a 120 mesh sieve, put into a crucible and pre-fired at 850°C for 2.5 hours to obtain sodium bismuth titanate powder, and used a self-sealing Bags are packaged for storage.

[0047] According to the molar ratio of 1:1, CaCO 3 and TiO 2Weigh, use deionized water as the medium, ball mill for 8 hours, dry at 120°C, pass through a 80-mesh sieve, and calcinate at 1060°C for 3 hours to obtain the CaTiO 3 , and sealed in a ziplock bag for storage.

[0048] Weigh H according to the ratio ...

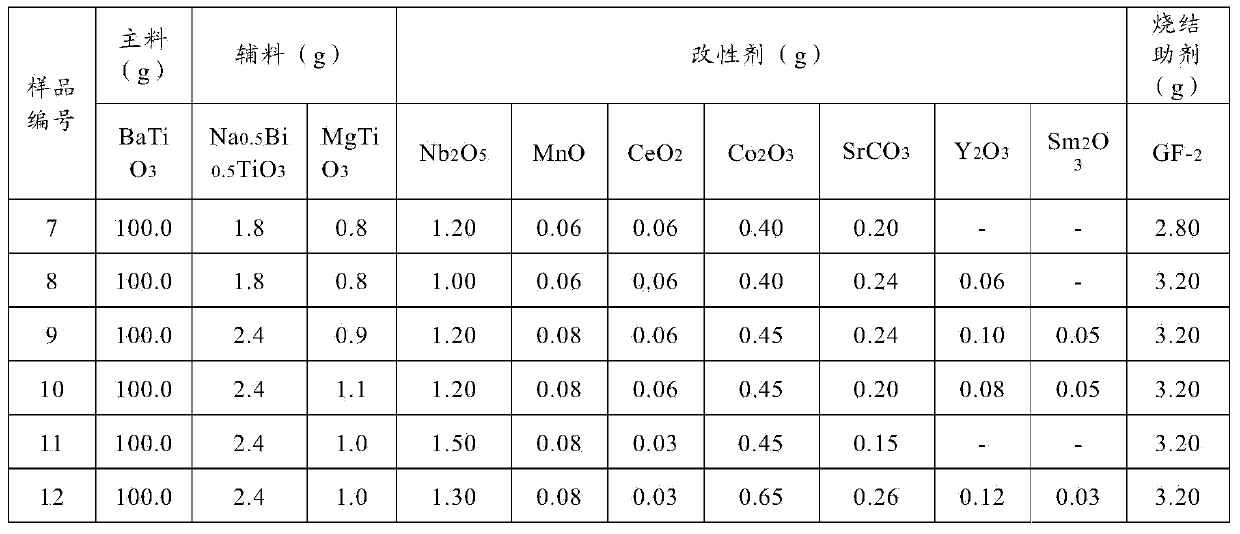

Embodiment 2

[0056] A temperature-stable X8R type MLCC dielectric material with bias characteristics for medium-temperature sintering is composed of main materials, auxiliary materials, modifiers and sintering aids. Among them, the main material BaTiO 3 Granularity D 50 =0.75 μm, purity ≥99.8%.

[0057] Weigh Bi according to the molar ratio of 1.01:1.01:4 2 o 3 、Na 2 CO 3 and TiO 2 , mixed ball milling with absolute ethanol as medium for 10 hours, dried at 80°C for 6 hours, ground and passed through a 120-mesh sieve, put into a crucible and pre-fired at 850°C for 2.5 hours to obtain sodium bismuth titanate powder.

[0058] According to the molar ratio of 1:1, Mg(OH) 2 and TiO 2 Weigh, use deionized water as the medium, ball mill for 8 hours, dry at 120°C, pass through a 80-mesh sieve, and calcined at 1080°C for 3 hours to obtain the MgTiO 3 .

[0059] Weigh H according to the ratio of weight ratio 1:0.8:2.2:0.6 3 BO 3 , CaCO 3 , ZnO and SiO 2 ;Choose deionized water as the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com