Straw-waste paper mixed fiber cushioning material and preparation method thereof

A technology of waste paper fibers and mixed materials is applied in the field of preparation of buffer packaging materials, which can solve the problems of high cost, difficult process, complicated operation process, etc., and achieve the effects of good buffer performance, wide application range and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] 1) Crushing the corn stalks in a pulverizer, soaking and softening the waste corrugated cardboard, and pulping and mixing them at a ratio of 1:2 for later use.

[0030] 2) Take 15%-20% of the mixed fiber and put it in 5% NaOH solution for pretreatment, which is equivalent to 7.5 times the amount of dry mixed slurry. Mix evenly in a water bath at 40°C. After pretreatment for 30 minutes, take out Rinse with water until neutral.

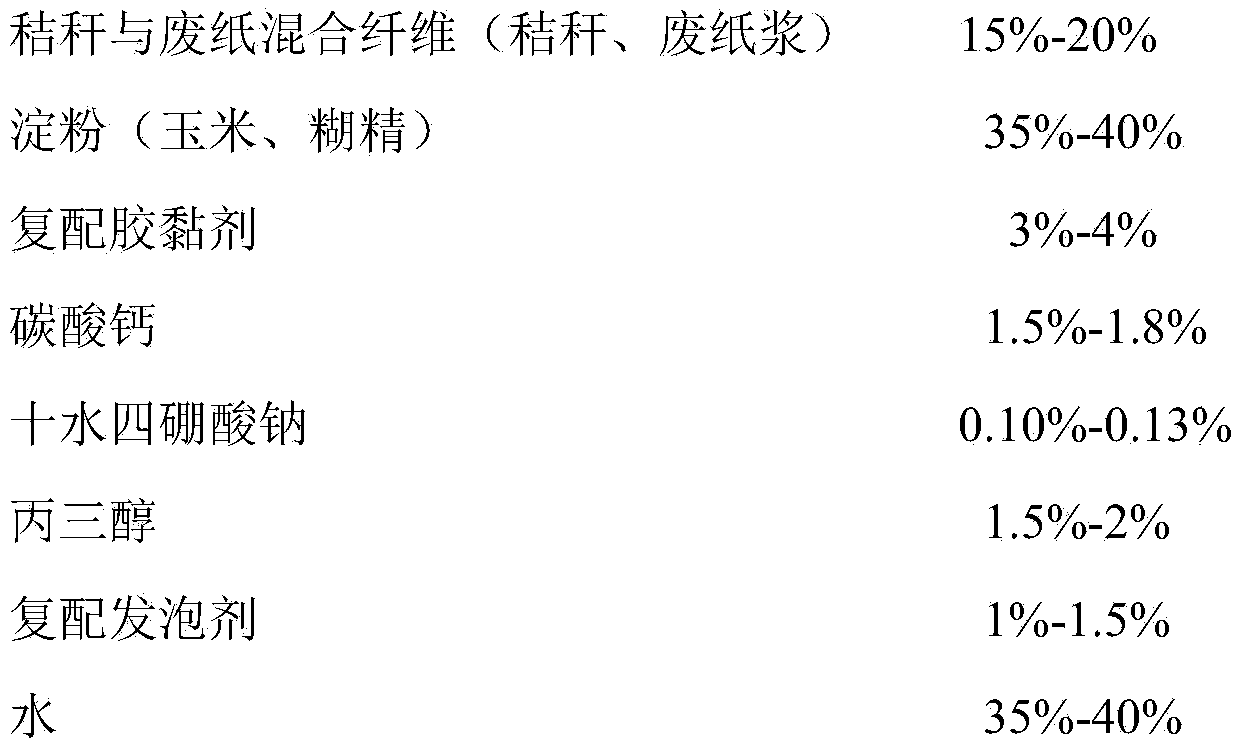

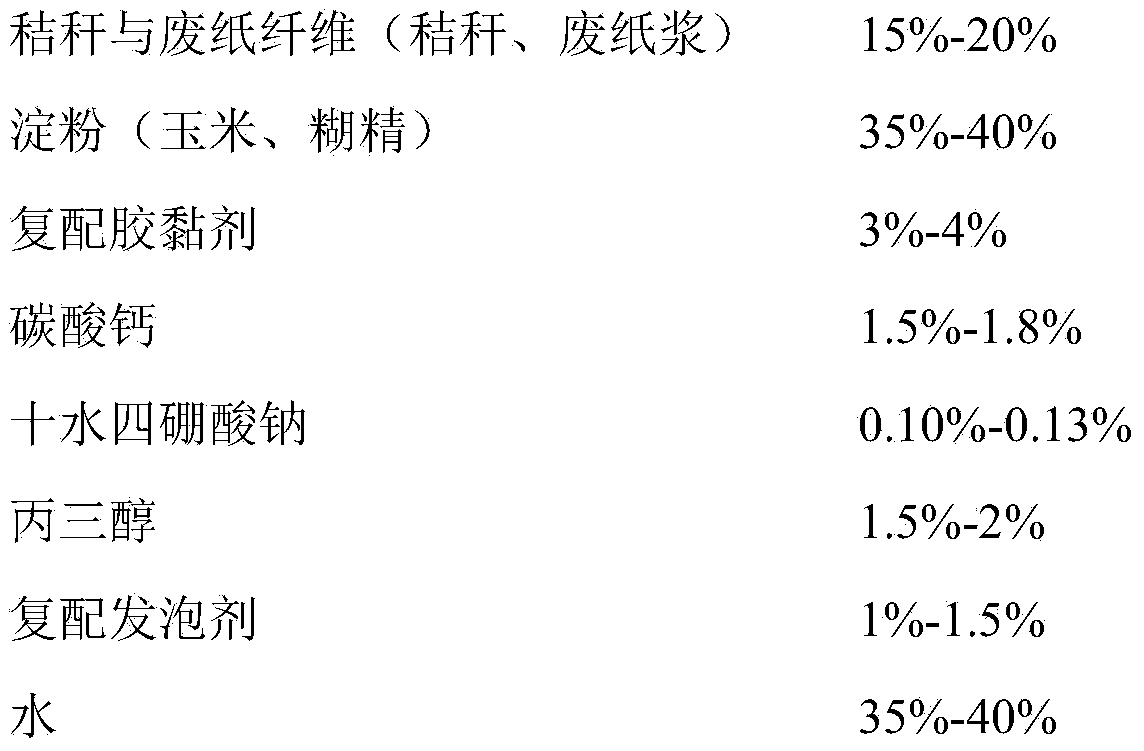

[0031] 3) Cooked starch 35%-40%, compound adhesive 3%-4%, calcium carbonate 1.5%-1.8%, sodium tetraborate decahydrate 0.10%-0.13%, glycerol 1.5%-2%, 1%-1.5% of the compound foaming agent and 35%-40% of water are stirred and mixed evenly, and then added to the mixed slurry and stirred to make it fully mixed.

[0032] 4) Put the mixture into a specific mold, put it in a microwave oven, the power is 640W, and the time is 12min, and the foamed product is obtained, and then the product is dried in a blast drying oven to a constant weight, and placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com