Cell patterning structure, preparation method and application in cell proliferation inhibition

A cell pattern, cell technology, applied in biochemical equipment and methods, immobilized on/in organic carriers, bioreactors/fermenters for specific purposes, etc., to achieve easy access to equipment, convenient operation methods, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 30mg PS (purchased from Sigma-Aldrich, molecular weight: 350,000) and 0.5mg DDAB in 5mL dichloromethane to prepare an organic polymer solution, mix 50μL deionized water with 1mL polymer organic solution, and sonicate for 10min Obtain a microemulsion, filter this microemulsion with a 220nm filter head, and drop 20 μL of the obtained filtrate on a smooth glass that has been washed with deionized water, ethanol, and deionized water in sequence at a humidity of 30% and a temperature of 25°C. on the base. After the dichloromethane and deionized water are completely volatilized, an ordered porous film with a pore diameter of about 5.5 μm and a pore depth of about 2 μm is obtained on the surface of the polymer membrane of the substrate.

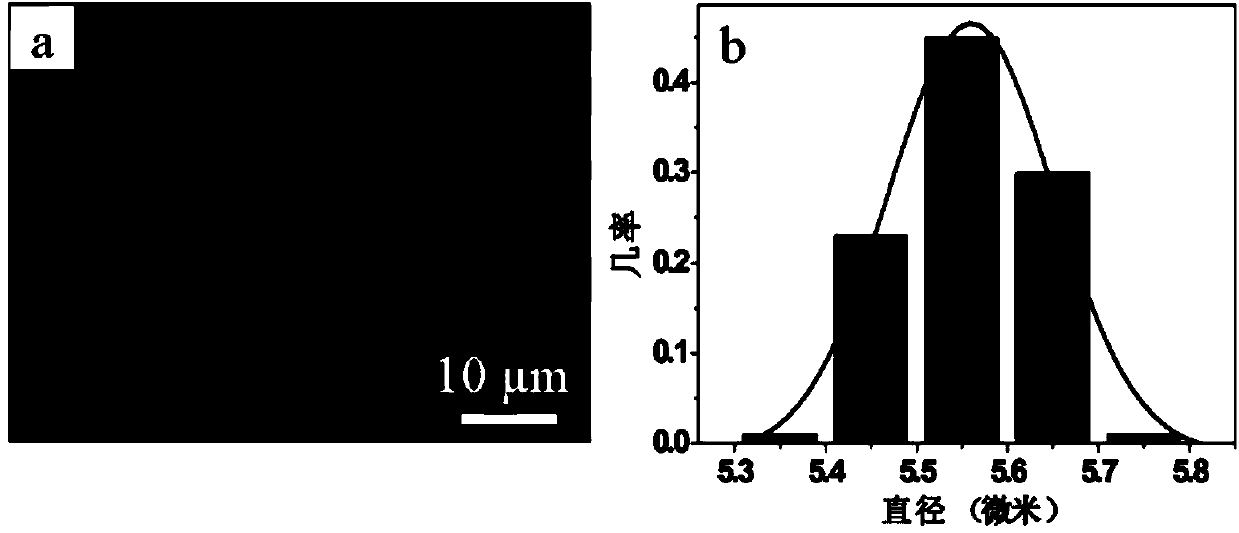

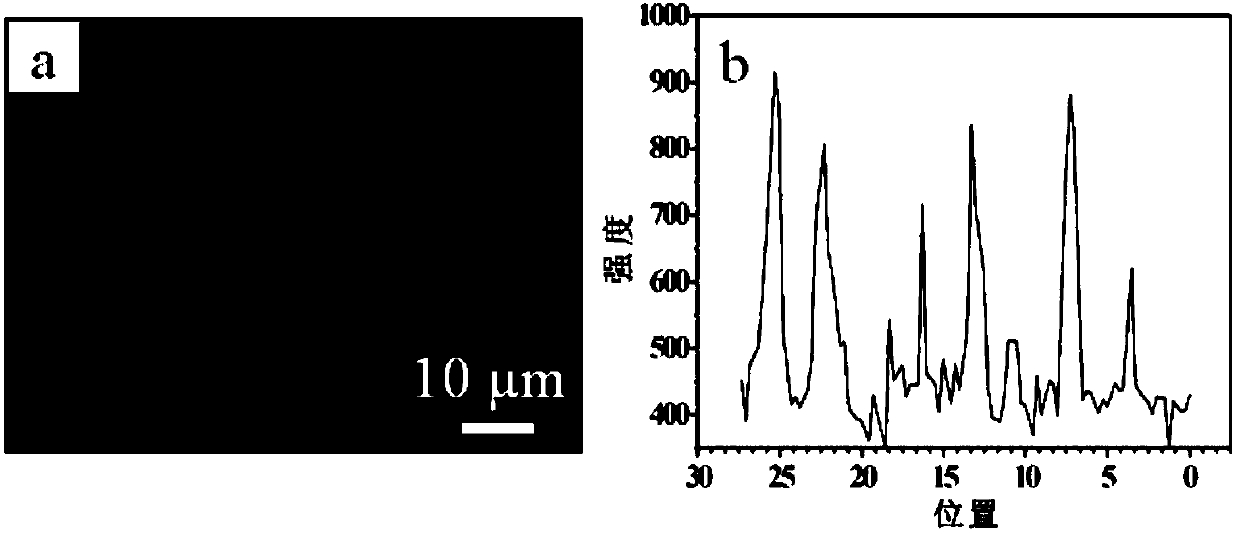

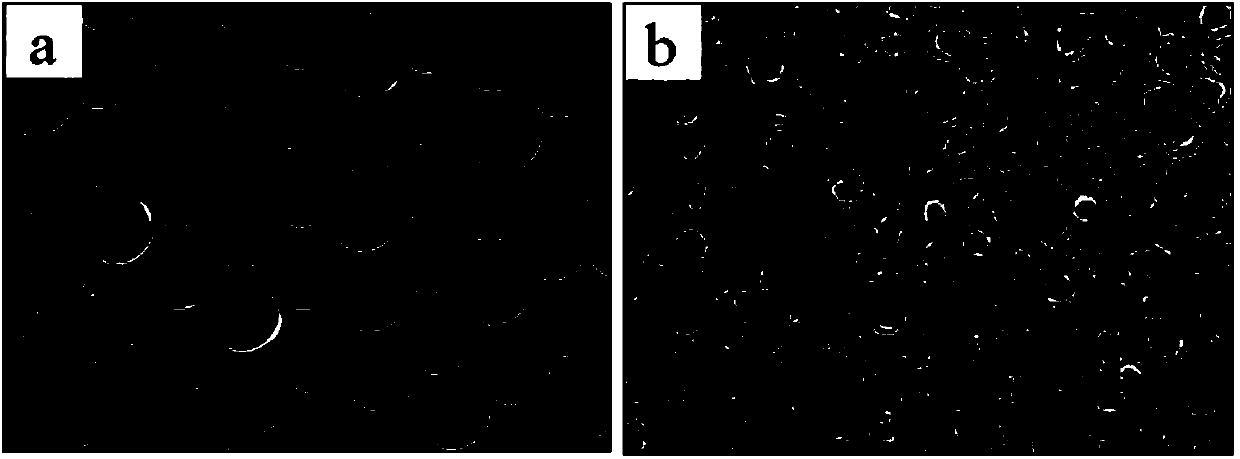

[0022] attached figure 1 is the scanning electron micrograph of the obtained ordered porous film and the Gaussian distribution diagram of the hole size. figure 1 a is the scanning electron micrograph of the prepared film, which sho...

Embodiment 2

[0029] As shown in Example 1, other conditions remain unchanged, the mass of DDAB is changed to 1.0 mg, the film-making temperature is changed to 30 ° C, and the humidity is changed to 40%, to obtain an organic film with a pore diameter of about 4 μm and a pore depth of about 1.8 μm. Sequenced porous films.

[0030] Then, according to the steps of Example 1, the assembly of polyelectrolyte PSS and PEI in the well, the selective distribution of cells in the well and the inhibition of cell proliferation based on the selective distribution were realized respectively.

Embodiment 3

[0032] As shown in Example 1, other conditions remain unchanged, and the negatively charged polyelectrolyte PSS is replaced by PAA to realize the assembly of PAA and PEI in the well, and then according to the steps in Example 1 to realize the selective distribution and distribution of cells in the well. Inhibition of cell proliferation based on selective distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com