IE-grade instrument cable for third-generation passive nuclear power plant gentle environment and production method

A technology for instrumentation cables and nuclear power plants, which is applied in the production field of IE-level instrumentation cables and production fields in third-generation passive nuclear power plants and moderate environments. It can solve problems such as fuel use restrictions, and achieve the effects of increasing service life, improving insulation, and excellent radiation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

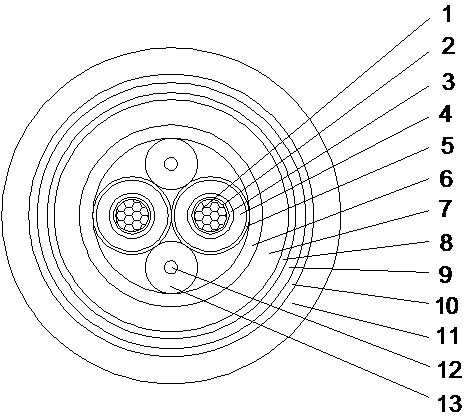

[0029] Reference attached figure 1 , third-generation passive nuclear power plant mild environment IE grade instrument cable, including two cores and two filler cores; the core includes a conductor 1, and the outer wall of each conductor 1 is wrapped with the first tape 2, the first tape 2 The inner insulating layer 3 and the outer insulating layer 4 are extruded and wrapped with a second wrapping tape 5; the filling core includes a reinforcing core 12, the reinforcing core 12 is extruded and wrapped with a filler 13, the reinforcing core 12 is aramid yarn, and the filler 16 is made of halogen-free low-smoke radiation cross-linked polyolefin; the filler core and the wire core are arranged symmetrically about the center, and are cut and stranded with each other to form a cable core. The cable core is sequentially provided with a cladding layer 6 and a filling layer 7. Inner shielding layer 8, outer shielding layer 9, wrapping layer 10 and jacket layer 11.

[0030] In this embo...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that it includes a positive electrode conductor and a negative electrode conductor, the positive electrode is a nickel-chromium alloy wire, and the negative electrode conductor is a nickel-silicon alloy wire.

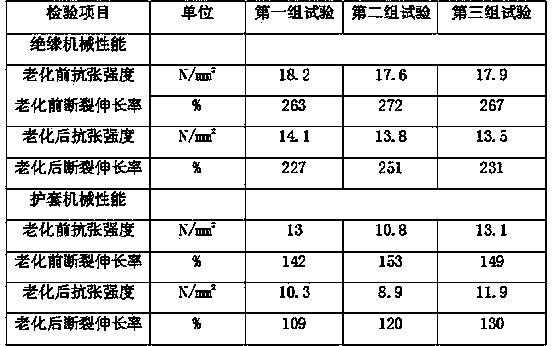

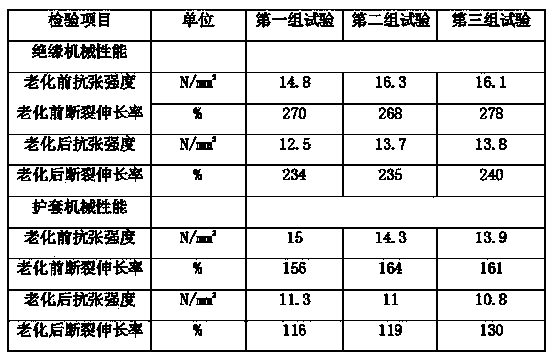

[0063] The cable test of the present invention has the following properties:

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com