Edible mushroom powder product and preparation method thereof

A technology of edible fungus and mushroom powder, which is applied in the direction of protein food composition, application, food science, etc. It can solve the problems of low extraction utilization rate of raw materials, poor nutrition and umami retention, etc., and achieve the regulation of human immunity and good seasoning Function, improve the effect of nutrient dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An edible fungus multi-mushroom powder, the composition of parts by weight is as follows: hickory chick enzymolysis powder 10, Bailing mushroom enzymolysis powder 15, animal protein hydrolysis powder 3, salt 0.2;

[0029] The preparation process of the hickory chick enzymatic hydrolysis powder is as follows: the hickory chick is prepared by fermentation, adjusted to 45°C after the fermentation, adding 1% of the weight of the fermentation broth to enzymatically hydrolyze the cellulase, the temperature is 45°C, the pH is 5, The time is 1 hour; add 0.5% of the weight of the fermentation broth to enzymatic hydrolysis treatment of flavor protease, the enzymatic hydrolysis temperature is 50°C, the pH value is 7, and the enzymatic hydrolysis time is 2 hours; adjust the temperature to 100°C and keep it for 6 minutes, maintain this temperature and centrifuge and maintain the rotation speed At 4000rpm; centrifuge the supernatant and dry to obtain hickory chick enzymolysis powder. ...

Embodiment 2

[0048] An edible fungus multi-mushroom powder, the composition of parts by weight is as follows: 15 hickory chick enzymatic hydrolyzed powder, 10 Bailing mushroom enzymatic hydrolyzed powder, 2 animal protein hydrolyzed powder, and 0.05 salt;

[0049] The preparation process of the hickory chick enzymatic hydrolysis powder is as follows: the hickory chick is prepared by fermentation, adjusted to 60°C after the fermentation, adding 2% of the weight of the fermentation broth to enzymatically hydrolyze the cellulase, the temperature is 50°C, the pH is 4. 5. The time is 0.5 hours; add 1% of the weight of the fermentation broth to enzymatically hydrolyze the flavor protein, the enzymolysis temperature is 45°C, the pH value is 6.5, and the enzymolysis time is 1 hour; adjust the temperature to 100°C for 5 minutes, and maintain this temperature for centrifugation. Keep the rotational speed at 4500 rpm; centrifuge the supernatant and dry to obtain morel enzyme hydrolysis powder.

[005...

Embodiment 3

[0068] The basic method is the same as Example 1 and Example 2;

[0069] An edible fungus multi-mushroom powder, the composition of parts by weight is as follows: hickory chick enzymolyzed powder 5, Bailing mushroom enzymatically hydrolyzed powder 20, animal protein hydrolyzed powder 5, salt 0.1;

[0070] The composition of the hickory chick fermentation liquid fermentation medium is: 2% millet, 1% peptone, 1% beef extract, 2.5% corn, 0.5% potassium dihydrogen phosphate, 20% Achyranthes bidentata and Eucommia enzymatic hydrolyzate; Supplemented with water, pH7.0-7.2, sterilized by high pressure steam at 121°C for 20min.

[0071] The product preparation process of the present invention is as follows:

[0072] Weigh each raw material according to the formula, mix it evenly, sterilize it by microwave, and pack it to be the product.

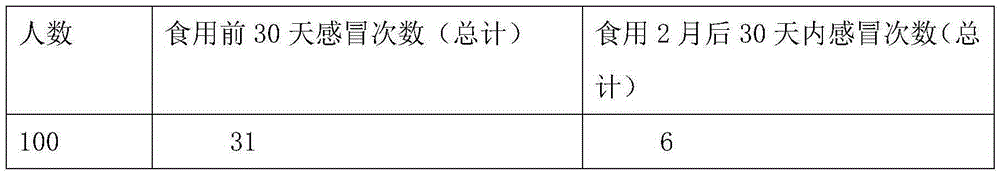

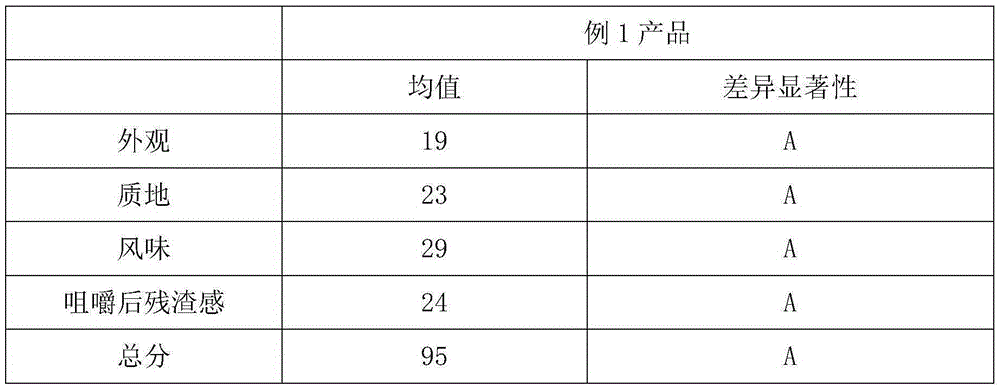

[0073] The product of Example 1 of the present invention is selected in winter by 100 elderly people aged 60-75 who are weak and prone to colds in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com