Regenerable oily denitration absorption liquid used for absorbing nitric oxides in smoke as well as preparation method and application of absorption liquid

A technology of nitrogen oxides and absorption liquid, which is applied in the field of renewable oil-based denitrification absorption liquid and its preparation, can solve the problems of being unable to recycle and reuse, and achieve the effects of low overall operating cost, convenient source, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The total flue gas volume of a 35t / h biomass boiler is 50,000 to 60,000 m 3 / h, measured flue gas SO before purification 2 The concentration is 600~750mg / m 3 ;NO x The concentration is 350~550mg / m 3 . The absorption tower is a spray tower with a height of 15m, a diameter of 3m, and a gas residence time of >4s. During the absorption process, control the reaction temperature of the absorption liquid to be about 50°C and the pH to be 6-7.

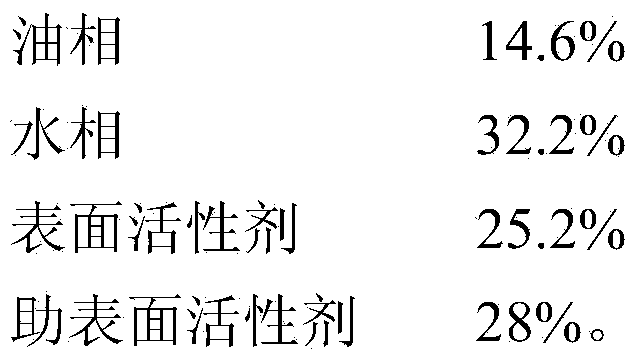

[0061] Under the temperature condition of 25°C, take 25.7% surfactant Span 60 and 25.7% co-surfactant n-butanol, mix well, add 15.6% diesel oil in proportion, mix well, and finally add 33% dimethyl methylene Sulfone, stir while adding until the solution becomes a clear and uniform liquid, that is, a stable oily denitrification absorption solution is formed, which can stand for a long time without stratification. Take 15% of the oily absorbing liquid, and the rest is ammonia water, and prepare the absorbing liquid.

[0062] During...

Embodiment 2

[0064] The total flue gas volume of a 35t / h biomass boiler is 50,000 to 60,000 m 3 / h, measured flue gas SO before purification 2 The concentration is 600~750mg / m 3 ;NO x The concentration is 350~550mg / m 3 . The absorption tower is a spray tower with a height of 15m, a diameter of 3m, and a gas residence time of >4s. During the absorption process, control the reaction temperature of the absorption liquid to be about 50°C and the pH to be 6-7.

[0065] Under the temperature condition of 25°C, take 28% surfactant Tween and 29% co-surfactant isoamyl alcohol, mix well, add 10% silicone oil in proportion, mix well, and finally add 33% DMSO in proportion , Stir while adding until the solution turns into a clear and uniform liquid, that is, a stable oily denitrification absorption solution is formed, which can stand for a long time without stratification. Take 20% of the oily absorbing liquid, and the rest is ammonia water, and prepare the absorbing liquid.

[0066] During the...

Embodiment 3

[0068] The total flue gas volume of a 35t / h biomass boiler is 50,000 to 60,000 m 3 / h, measured flue gas SO before purification 2 The concentration is 600~750mg / m 3 ;NO x The concentration is 350~550mg / m 3 . The absorption tower is a spray tower with a height of 15m, a diameter of 3m, and a gas residence time of >4s. During the absorption process, control the reaction temperature of the absorption liquid to be about 50°C and the pH to be 6-7.

[0069] At 25°C, take 23.4% surfactant TX-10 and 12.5% co-surfactant isobutanol, mix well, add 26.8% diesel oil in proportion, mix well, and finally add 37.3% dimethyl methylene Sulfone, stir while adding until the solution becomes a clear and uniform liquid, that is, a stable oily denitrification absorption solution is formed, which can stand for a long time without stratification. Take 40% of the oily absorbing liquid, and the rest is ammonia water to prepare the absorbing liquid.

[0070] During the production process, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com