Mixed matrix membrane as well as preparation method and application of mixed matrix membrane

A mixed-matrix membrane and membrane-forming technology, applied in separation methods, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

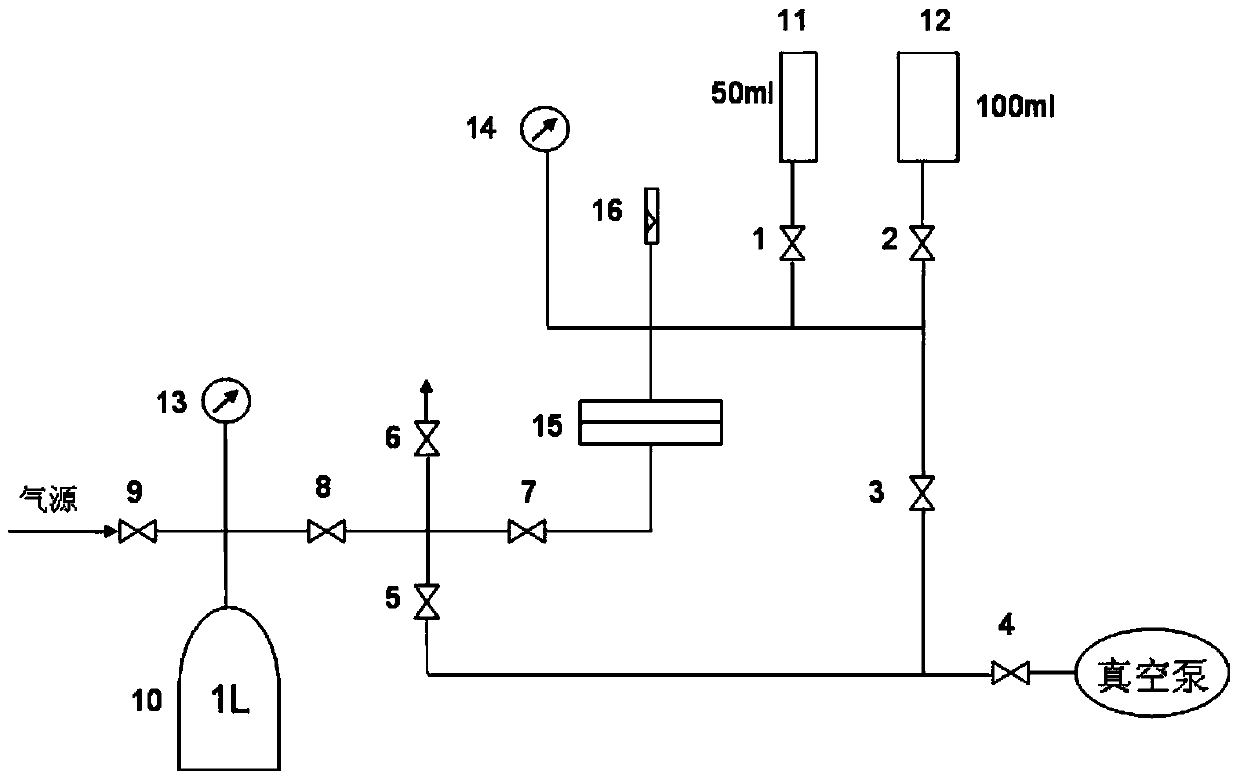

Method used

Image

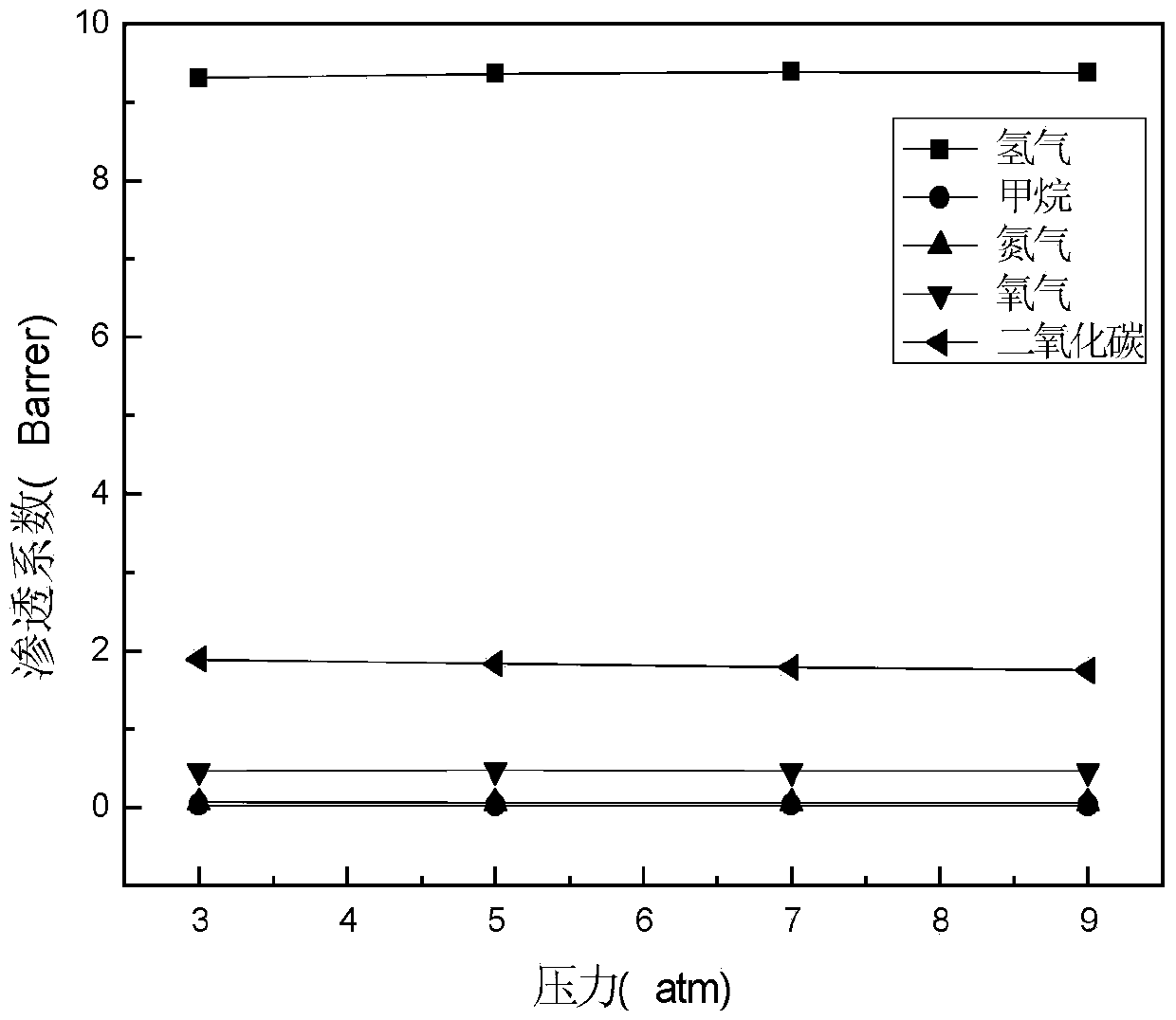

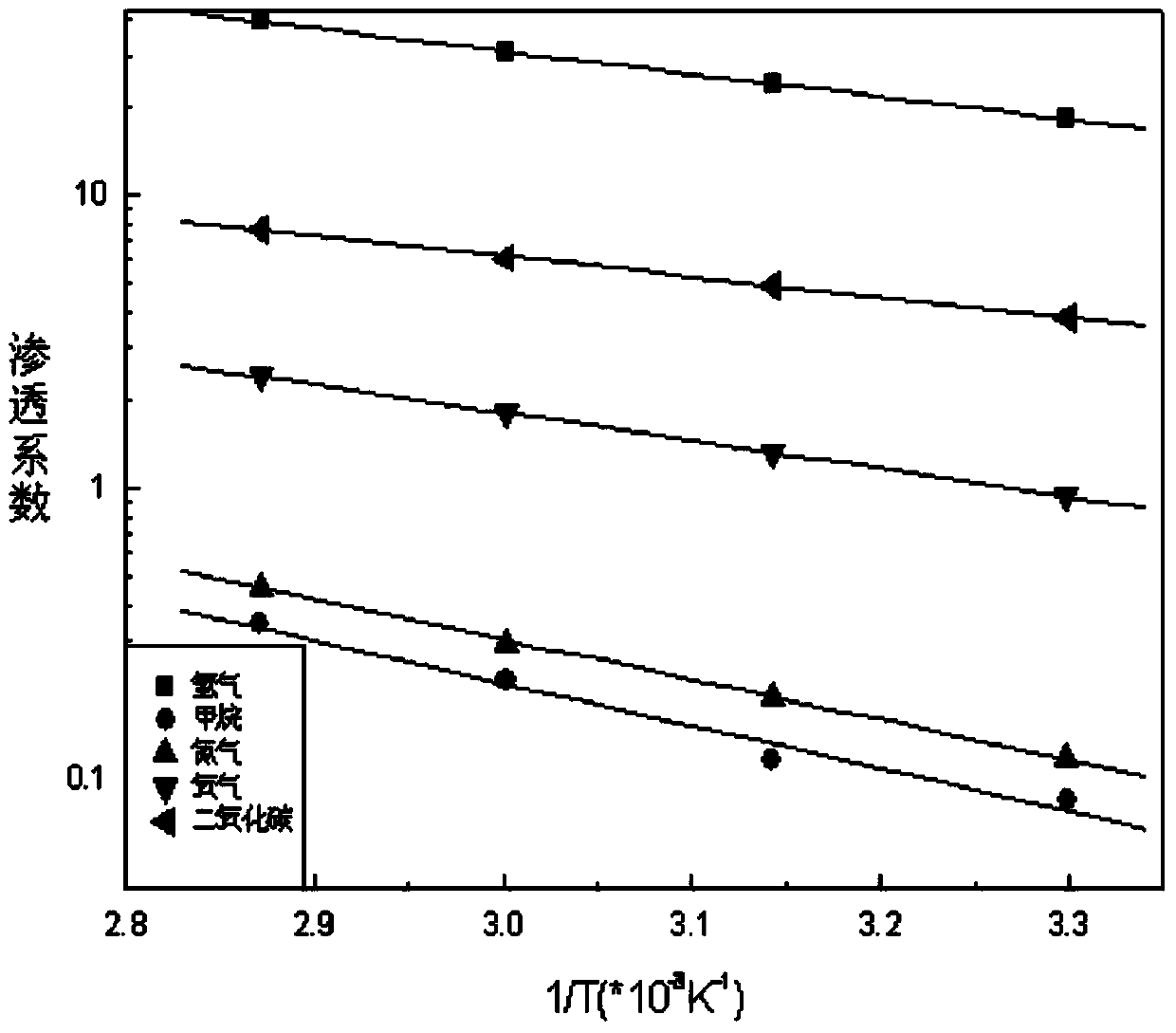

Examples

preparation example Construction

[0039] In yet another typical embodiment of the present invention, a method for preparing a mixed matrix membrane is provided. The preparation method includes: step S1, preparing a solution of polyetherimide; step S2, dispersing molecular sieves in polyetherimide In the imine solution, a casting solution is obtained; step S3, using the casting solution to form a film. In this preparation method, the casting liquid can be obtained by dispersing the molecular sieve in the prepared polyetherimide solution, and then the film is prepared. The above-mentioned dispersion process is a physical process without chemical reaction, and the whole preparation process does not require high equipment, which is beneficial to industrialization.

[0040] In the above step S1, different solvents can be selected according to the type of polyetherimide selected for preparation. Commonly used solvents include dimethylacetamide, dimethylformamide, and N-methylpyrrolidone , tetrahydrofuran or dichlor...

Embodiment 1

[0048] Add 0.95g of the powdery intrinsic viscosity after vacuum oven drying to 40ml / g HQDEA-DMMDA new polyetherimide PEI into 50g of dichloromethane solvent, and stir at room temperature (20-30°C) for 8 hours to form a uniform and transparent polymer solution.

[0049] Add 0.05g of SAPO-34 molecular sieve to the polymer solution, stir vigorously for 15min at a low temperature of 4°C at a speed of 1000rpm, ultrasonicate for 2h to form a slightly whitish homogeneous solution, and let it stand for 24 hours for defoaming;

[0050] Pour the defoamed casting solution onto a clean horizontal glass plate, spread the casting solution evenly on the glass plate, keep the temperature of the glass plate at room temperature (20-30°C), and control the air humidity at 30%. The solvent is volatilized to finally form a primary film. Carefully remove the nascent film from the glass plate, put it in a vacuum oven, dry at 60°C for 48h, and then vacuum at 120°C for 24h to further remove the resi...

Embodiment 2

[0052] Add 0.9g of the powdery intrinsic viscosity after vacuum oven drying to 80ml / g HQDEA-DMMDA new polyetherimide PEI into 50g of dichloromethane solvent, stir at room temperature (20-30°C) for 8h, and form a uniform and transparent polymer solution;

[0053] Add 0.1 g of SAPO-34 molecular sieve to the polymer solution, stir vigorously at 10°C for 15 min at a speed of 1500 rpm, ultrasonicate for 2 h to form a slightly whitish homogeneous solution, and then press at - Degassing at 0.06MPa;

[0054] Pour the defoamed casting solution onto a clean horizontal glass plate, spread the casting solution evenly on the glass plate, keep the temperature of the glass plate at room temperature (20-30°C), and control the air room temperature at 20%. The solvent is volatilized to finally form a primary film. Carefully remove the nascent film from the glass plate, put it in a vacuum oven, dry at 60°C for 48h, and then vacuum at 120°C for 24h to further remove the residual solvent to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com