An iron-based cermet composite guide roller and its sintering and welding integration process

A metal-ceramic composite and ceramic composite technology, which is applied in the welding integration process, iron-based metal-ceramic composite guide roll and its sintering field, can solve the frequent shutdown of high-speed wire rod rolling production lines, reduce the production efficiency of high-speed wire rod mills, and increase the production of guide rolls Cost and other issues, to achieve the effect of being convenient for large-scale promotion and use, easy to operate, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

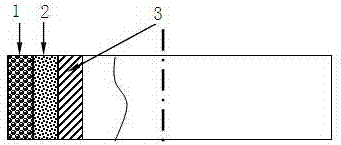

[0022] see figure 1 : A kind of iron-based cermet composite guide roller, wherein the composite guide roller is successively high ceramic layer 1, high metal layer 2, annular steel block 3 from outside to inside, and the concrete formula of described high ceramic layer is 50wt% 400 Mesh TiC powder, Fe powder is 39wt%, Mo powder is 1wt%, Ni powder is 3wt%, Cr powder is 7wt%; the transition layer is a high metal layer, the specific formula is 25wt% 400 mesh TiC powder, Fe powder is 62wt %, Mo powder is 1wt%, Ni powder is 4wt%, Cr powder is 8wt%; the particle size of the above metal powders are all 200 mesh.

Embodiment 2

[0023] Example 2: see figure 1 , an iron-based cermet composite guide roller, wherein the composite guide roller is successively composed of a high ceramic layer 1, a high metal layer 2, and an annular steel block 3 from outside to inside, and the specific formula of the high ceramic layer is: 40wt% 400 mesh TiC powder, Fe powder is 47wt%, Mo powder is 1wt%, Ni powder is 4wt%, Cr powder is 8wt%; Inner layer formula 20wt% 400 mesh TiC powder, Fe powder is 67wt%, Mo powder is 1wt%, Ni powder 4wt%, Cr powder 8wt%; the particle size of the above metal powders are all 200 mesh.

Embodiment 3

[0024] Embodiment 3: see figure 1 , an iron-based cermet composite guide roller, wherein the composite guide roller is successively composed of a high ceramic layer 1, a high metal layer 2, and an annular steel block 3 from outside to inside, and the specific formula of the high ceramic layer is: 30wt% of 400 mesh TiC powder, Fe powder is 57wt%, Mo powder is 2wt%, Ni powder is 4wt%, Cr powder is 7wt%; the inner layer formula 15wt% 400 mesh TiC powder, Fe powder is 72wt%, Mo powder is 2wt%, Ni powder 4wt%, Cr powder 7wt%; the particle size of the above metal powders are all 200 mesh. . This is done for uniform furnace temperature, so as to ensure uniform temperature of samples and uniform quality of sintered products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com