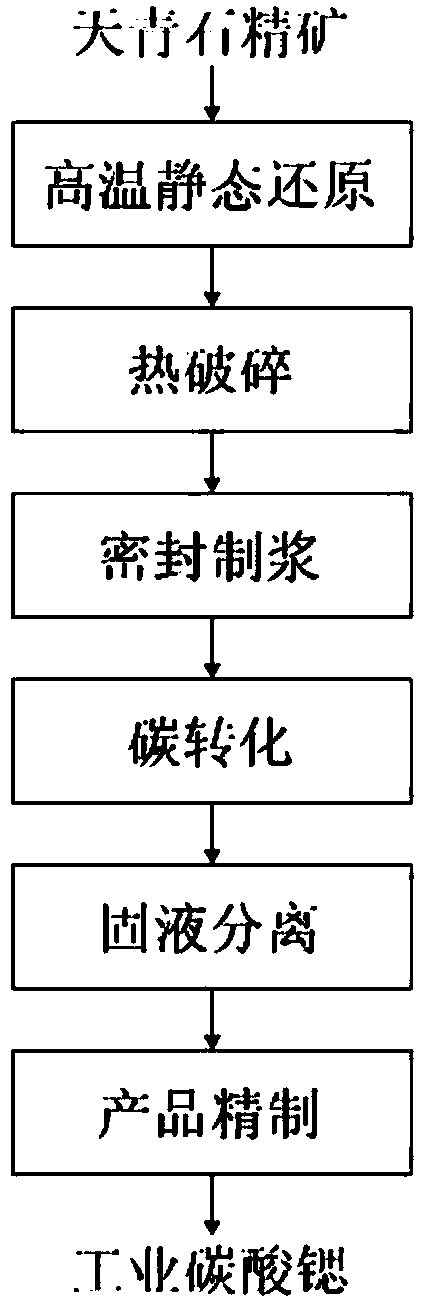

Method for synthesizing strontium carbonate from celestite by high-temperature static reduction-pressurization conversion

A technology of celestite and strontium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem that the reaction speed cannot be effectively improved, achieve the significance of strong industrial promotion, increase the carbonization reaction rate, and avoid the effect of hydrogen sulfide pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1kg of celestite concentrate and 0.1kg of carbon are fully mixed, pressed into pellets with a particle size of 50mm, and placed in a rotary hearth furnace for reduction roasting at 1200°C for 30min. When the calcined material is cooled to 500°C, it is crushed by a roller crusher until the percentage of the particle size is less than 100 mesh to 50%, and then transferred to the prepared conversion liquid in the autoclave (wherein the concentration of ammonium carbonate is 4mol / L, the concentration of ammonia water is 16mol / L, the concentration of ammonium chloride is 1mol / L, lignosulfonate 0.4%), immediately seal the dosing, the stirring speed is 800rpm, the liquid-solid ratio is 5:1, and the temperature of the autoclave is stable Reaction at 95°C for 2h. After the reaction is completed, the slurry is separated from the liquid to the solid, and the filter residue is crude strontium carbonate. The industrial strontium carbonate product with a purity of 98% can be obtain...

Embodiment 2

[0034] 1kg of celestite concentrate and 0.3kg of carbon are fully mixed, pressed into pellets with a particle size of 10mm, and placed in a rotary hearth furnace for reduction roasting at 1400°C for 10min. When the calcined material is cooled to 300°C, it is crushed by a roller crusher until the particle size is less than 100 mesh, and the percentage of the part is up to 75%, and then transferred to the prepared conversion liquid in the autoclave (wherein the concentration of ammonium carbonate is 2mol / L, the concentration of ammonia water is 8mol / L, the concentration of ammonium chloride is 0.3mol / L, and the concentration of lignosulfonate is 0.2%), immediately seal the dosing, the stirring speed is 600rpm, the liquid-solid ratio is 3:1, and wait for high pressure React for 4 hours when the kettle temperature stabilizes to 50°C. After the reaction is completed, the slurry is separated from the liquid to the solid, and the filter residue is crude strontium carbonate. The cru...

Embodiment 3

[0036] 1kg of celestite concentrate and 0.5kg of carbon are fully mixed, pressed into pellets with a particle size of 1mm, and placed in a rotary hearth furnace for reduction roasting at 1500°C for 20min. When the calcined material is cooled to 200°C, it is crushed by a roller crusher until the percentage of the particle size is less than 100 mesh to 80%, and then transferred to the prepared conversion liquid in the autoclave (wherein the concentration of ammonium carbonate is 1mol / L, the concentration of ammonia water is 4mol / L, the concentration of ammonium chloride is 0.1mol / L, and the concentration of lignosulfonate is 0.1%), immediately seal the dosing, the stirring speed is 200rpm, the liquid-solid ratio is 2:1, and wait for high pressure React for 1 hour when the kettle temperature stabilizes to 150°C. After the reaction is completed, the slurry is separated from the liquid to the solid, and the filter residue is crude strontium carbonate. The industrial strontium car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com