A kind of multiple reactor for removing tebuconazole in water and its system and method

A technology of reactor and tebuconazole is applied in the system field of removing tebuconazole in water, which can solve the problems of high operating cost, increased biological toxicity, complicated operation, etc., to improve the adsorption removal rate and biodegradation rate, reduce swelling and Effect of stacking pressure, avoiding breakage and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

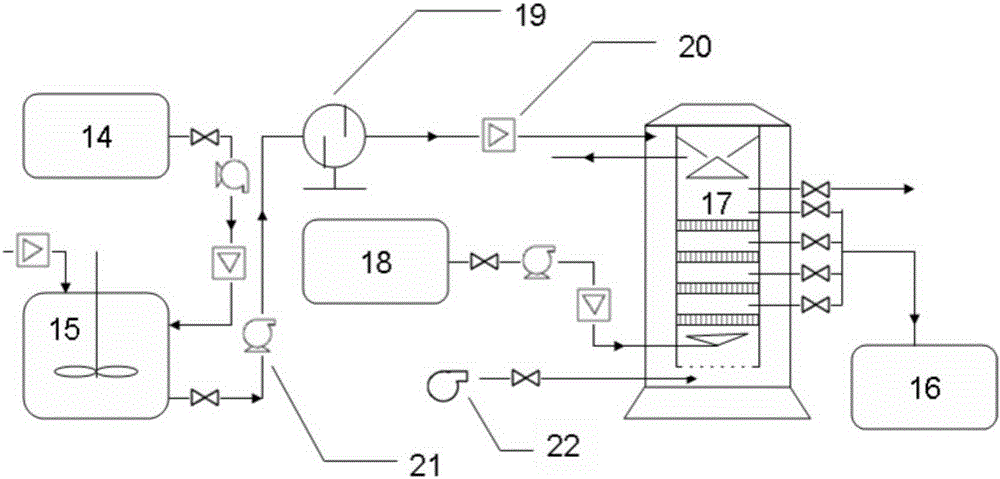

[0045] The overall structure of the processing pilot system is as follows image 3 As shown, it includes: additional nutrient solution storage tank 14, water inlet adjustment tank 15, backwash water collection tank 16, multiple reactor 17, backwash water storage tank 18, filter 19, flow meter 20, water pump 21, aeration pump 22. Wherein, the additional nutrient solution storage tank 14 links to each other with the water inlet adjustment tank 15, and the compound reactor 17 is respectively connected with the water inlet adjustment tank (15), the backwash water storage tank 18, the backwash water outlet water collection tank 16 and the aeration pump (22 ) are connected; a water pump 21, a filter 19 and a flow meter 20 are arranged between the compound reactor 17 and the water inlet regulating tank (15).

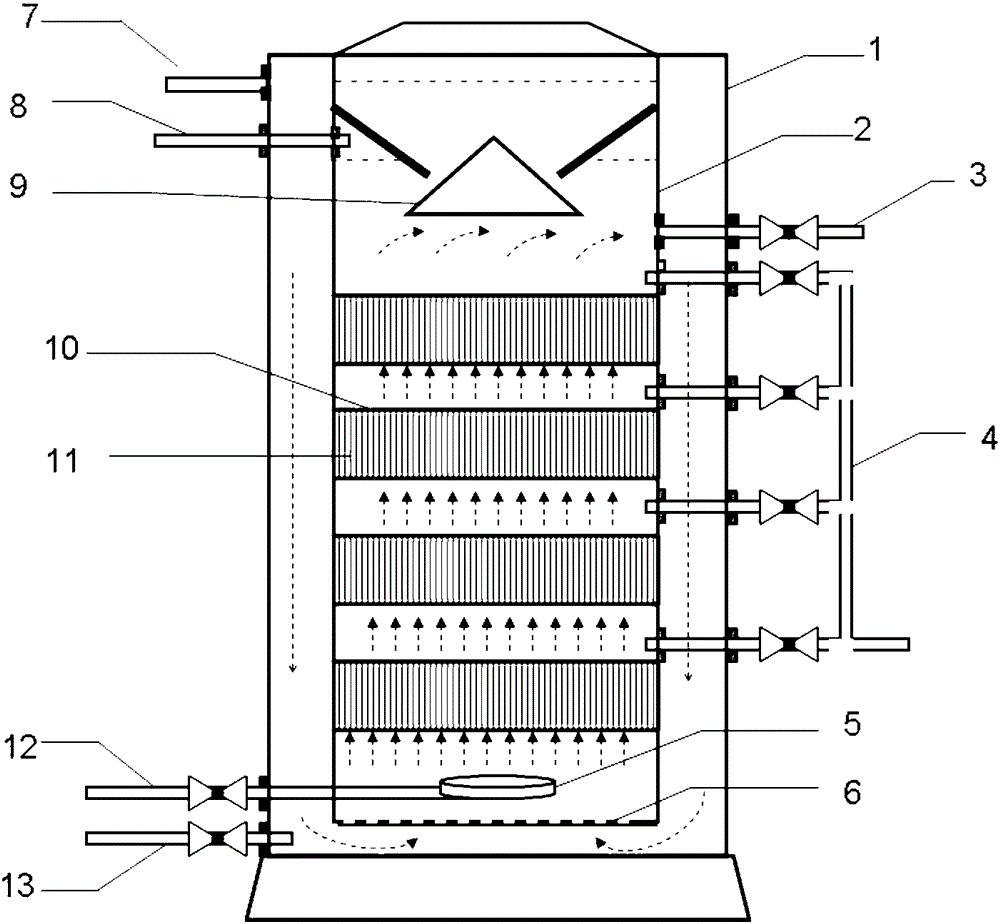

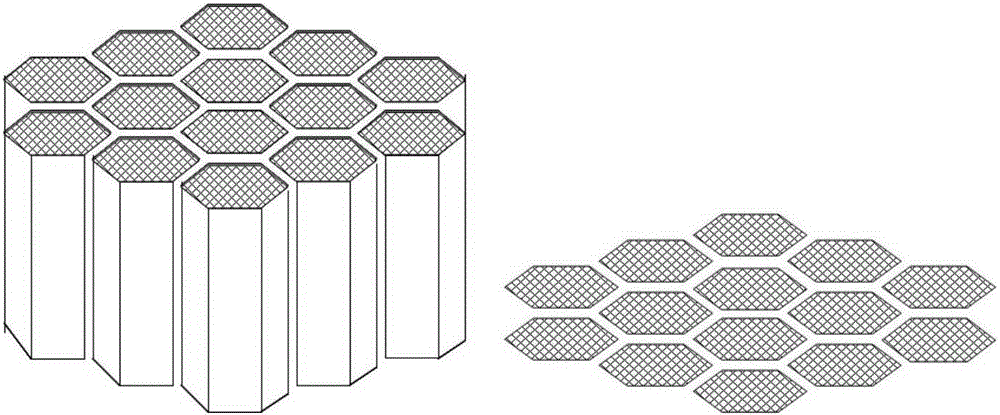

[0046] The multiple reactor 17 structure used is as figure 1 As shown, it includes: reactor shell 1, reactor inner shell 2, water inlet pipe 7, water distributor 6, water out...

Embodiment 2

[0060] The processing system used is the same as in Example 1.

[0061] Step 1, prepare the adsorbent resin loaded with microorganisms:

[0062] A. microbial culture: at first the sphingomonas (Sphingomonassp.) bacterium colony in the plate is inoculated into liquid beef peptone medium and cultured in the dark, 28 degrees Celsius of temperature;

[0063] b. Bacteria collection: Centrifuge the bacterium culture fluid in the logarithmic growth phase (centrifugation time 20 minutes, rotating speed 5000G), and the buffer solution (pH) prepared by disodium hydrogen phosphate and potassium dihydrogen phosphate for the isolated thalli = 7.3) cleaning;

[0064] c. Resin-loaded microorganisms: inoculate the collected bacteria into a mineral liquid medium, add polyacrylate adsorption resin, and carry out shaking culture for 4 days to obtain an adsorption resin loaded with microorganisms;

[0065] d. Filling resin: Clean the adsorption resin loaded with microorganisms with deionized wa...

Embodiment 3

[0072] The processing system used is the same as in Example 1.

[0073] Step 1, prepare the adsorbent resin loaded with microorganisms:

[0074]A. microbial culture: at first the sphingomonas (Sphingomonassp.) bacterium colony in the plate is inoculated into liquid beef peptone medium and cultured in the dark, 28 degrees Celsius of temperature;

[0075] b. Bacteria collection: Centrifuge the bacterium culture fluid in the logarithmic growth phase (centrifugation time 20 minutes, rotating speed 5000G), and the buffer solution (pH) prepared by disodium hydrogen phosphate and potassium dihydrogen phosphate for the isolated thalli = 7.3) cleaning;

[0076] c. Resin-loaded microorganisms: Inoculate the collected bacteria into a mineral liquid medium, add polystyrene adsorption resin, and carry out shaking culture for 5 days to obtain an adsorption resin loaded with microorganisms;

[0077] d. Filling resin: Clean the adsorption resin loaded with microorganisms with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com