Catalyst for purifying exhaust gas

A waste gas purification and catalyst technology, which is applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problems of absolute reaction area reduction and limited space, and achieve excellent gas purification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1

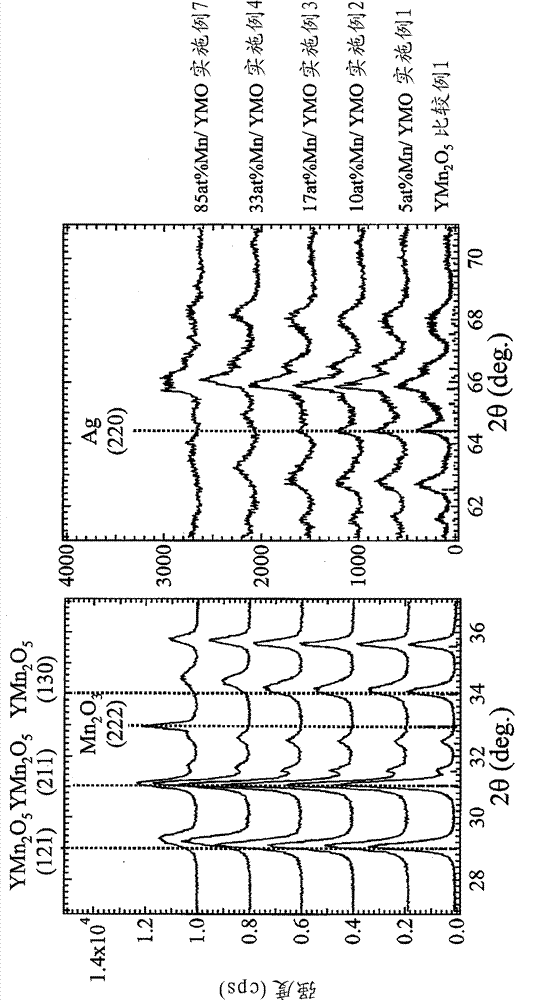

[0050] Mix Yttrium Nitrate solution with known metal concentration and Manganese Nitrate solution separately so that Y and Mn reach Mn / Y=2, adjust the concentration with ion-exchanged water so that YMO finally obtained reaches 50g / L, and make raw material liquid. To 2.5%NH 3 Ion-exchanged water was added to an aqueous solution obtained by mixing 26.59 mL of an aqueous solution and 11.33 mL of 30% hydrogen peroxide water to prepare 265.9 mL to prepare a precipitant. Thereafter, a precipitating agent is added dropwise to the raw material liquid to form a precipitate, and the obtained precipitate is filtered and washed, followed by heating to obtain a powder.

[0051] 37.5 g of water was added to 0.124 g of silver nitrate, and stirred to prepare an aqueous solution of silver nitrate. Further, manganese nitrate was added to form an aqueous solution so as to contain an excess of Mn shown in Table 1, and 1.5 g of the above was added to each aqueous solution. The obtained powder wa...

Embodiment 8~11

[0054] Separately prepare yttrium nitrate solution and manganese nitrate solution with known metal concentrations, mix them separately so that Y and Mn reach the Mn excess ratio shown in Table 1, and adjust the concentration with ion-exchanged water so that the finally obtained YMO reaches 50 g / L , so as to make the raw material liquid. On the other hand, towards 2.5%NH 3 Ion-exchanged water was added to an aqueous solution obtained by mixing 26.59 mL of an aqueous solution and 11.33 mL of 30% hydrogen peroxide water to prepare 265.9 mL to prepare a precipitant.

[0055] Thereafter, a precipitating agent is added dropwise to the raw material solution to generate a precipitate, and the precipitate is filtered and washed, followed by heating to obtain a powder.

[0056] 37.5 g of ion-exchanged water was added to 0.124 g of silver nitrate, and stirred to prepare an aqueous silver nitrate solution. 1.5 g of each of the above-mentioned powders was put into the solution and heated ...

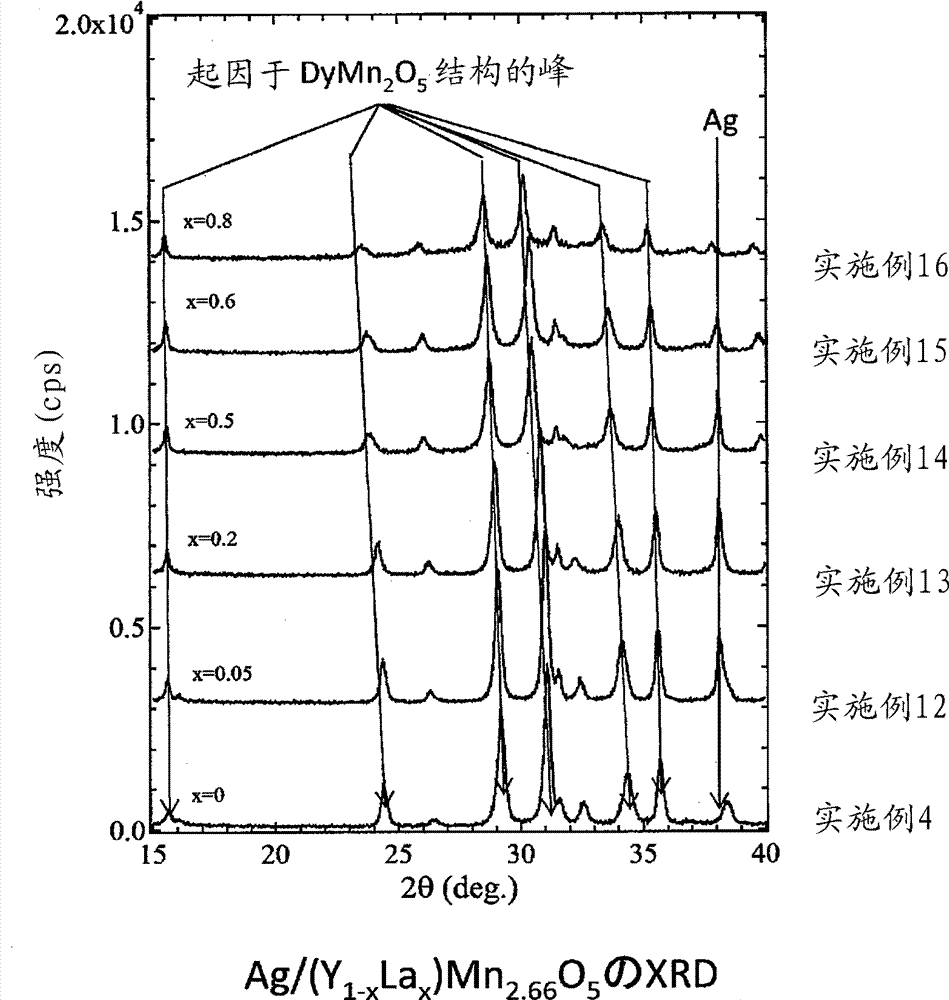

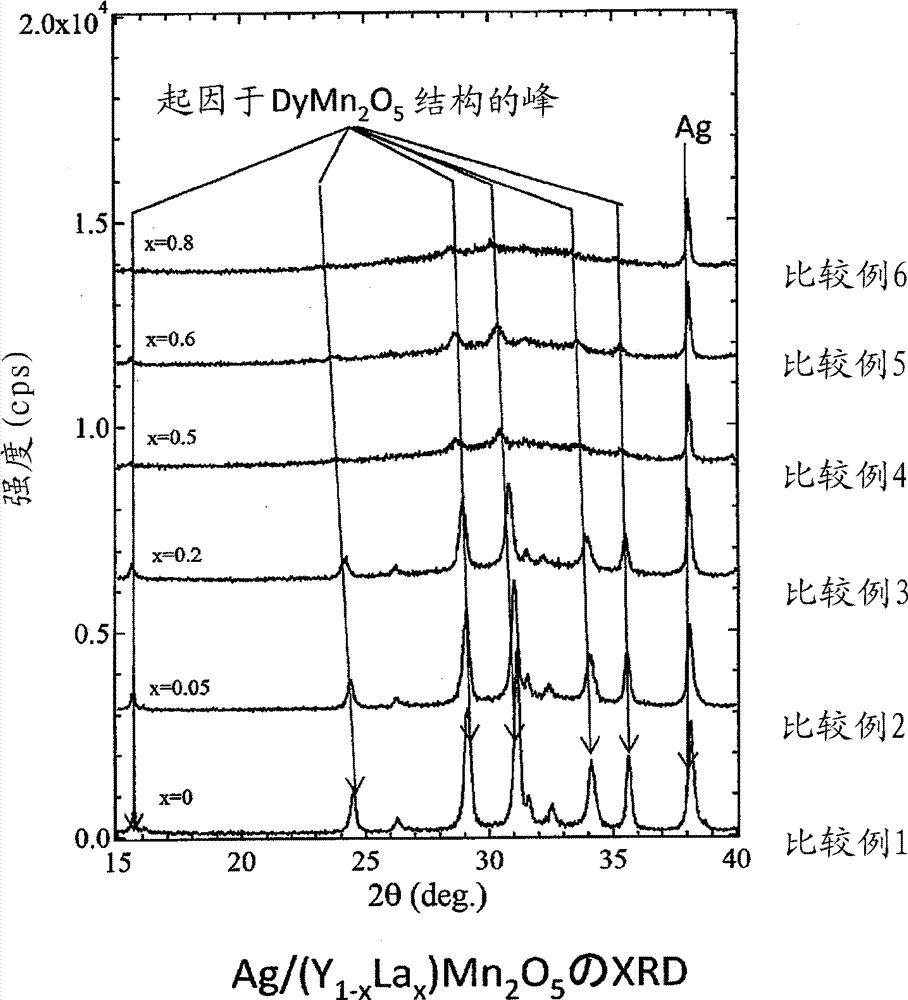

Embodiment 12~20

[0067] Yttrium nitrate solution, manganese nitrate solution and lanthanum nitrate solution were mixed separately in such a manner that Y and La reached the ratio shown in column a of Table 2 and (Y+La) and Mn reached the ratio shown in column b of Table 2, In addition, the same operation as in Example 1 is obtained by (Y 1-x La x )Mn 2+y o 5 The exhaust gas purification catalysts of Examples 12 to 20 made of multiple oxides. The Ag loading amount of the obtained catalyst for exhaust gas purification was 5.57% by mass based on the total mass of metal Ag+support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com