Heterogeneous catalysis ozone oxidation method for water treatment and device applied to the method

A technology of heterogeneous catalysis and ozone oxidation, applied in the field of water treatment, heterogeneous catalysis and ozone oxidation treatment of water, can solve the problems of small-sized solid catalyst loss, reduction of catalytic sites, uneven treatment, etc., to achieve improved decontamination Efficiency and operational stability, improved processing economy, and enhanced operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

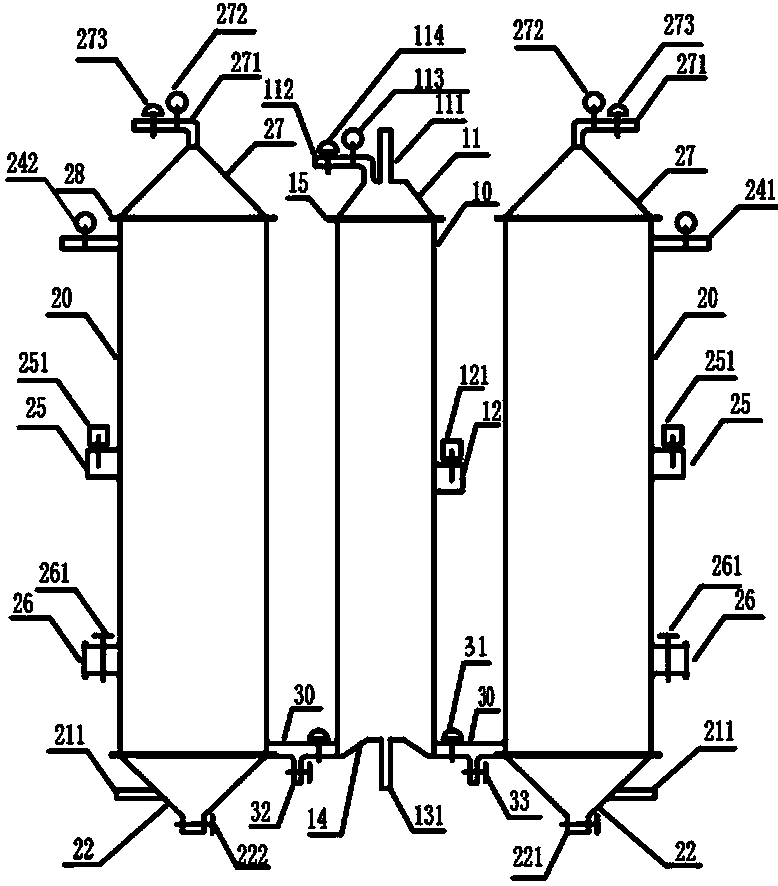

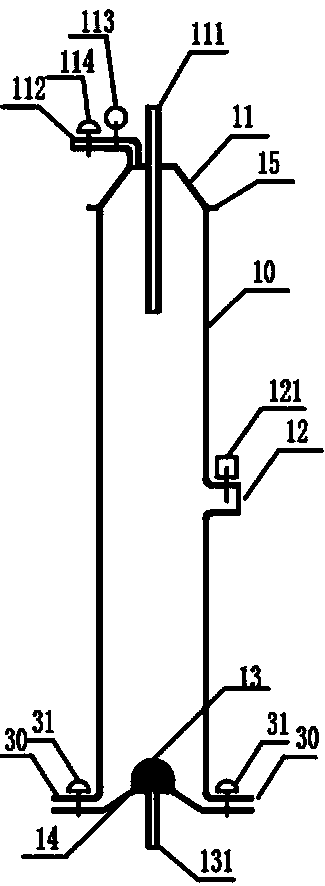

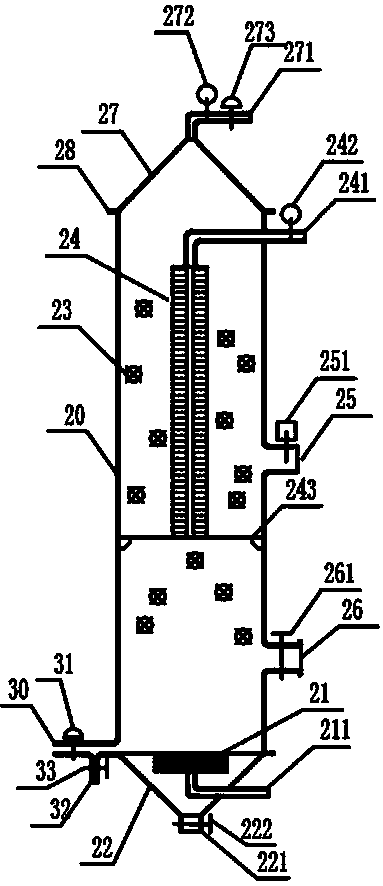

[0055] The invention is used to purify moderately eutrophic lake water. See attached Figure 1-3 , The heterogeneous catalytic ozonation treatment water device consists of a central contact tower 10, two radial flow connecting pipes 30 and two catalytic oxidation towers 20. Among them, the height of the central contact tower 10 is 900 mm, and the diameter of the tower is 120 mm; the height of the tower 20 of the catalytic oxidation tower is 900 mm, and the diameter of the tower is 170 mm; the central contact tower and the catalytic oxidation tower are connected by a radial connection pipe 30, The radial flow connecting pipe is provided with an electromagnetic throttle valve 31, and the radial flow connecting pipe is also provided with a sampling port 32, and the sampling port is provided with a stop valve 33; the top of the central contact tower is provided with a gas collecting hood 11; Lan 15 is connected with the tower body; the exhaust gas discharge pipe 112 is arranged o...

Embodiment 2

[0064] The invention is used for advanced treatment of biochemical effluent of a certain urban sewage treatment plant. See attached Figure 4, the heterogeneous catalytic ozonation water treatment device is composed of a central contact tower, 4 radial flow connecting pipes 30 and 4 catalytic oxidation towers; among them, the height of the central contact tower is 900 mm, and the diameter of the tower is 120 mm; The height of the catalytic oxidation tower is 900 mm, and the diameter of the tower is 170 mm; the central contact tower and the catalytic oxidation tower are connected through a radial flow connecting pipe 30, and the radial flow connecting pipe is equipped with an electromagnetic throttle valve 31, and the radial flow connecting pipe There is also a sampling port on the top, and the sampling port is provided with a stop valve; the top of the central contact tower is provided with a gas collecting hood 11; the gas collecting hood is connected to the tower body throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com