Metal-imitating ABS modified material and preparation method thereof

A modified material, imitating metal technology, applied in the field of plastic modification, can solve the problems of poor metal effect, weld marks, impact strength drop, etc., to overcome the impact strength drop, eliminate weld marks, and improve the effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

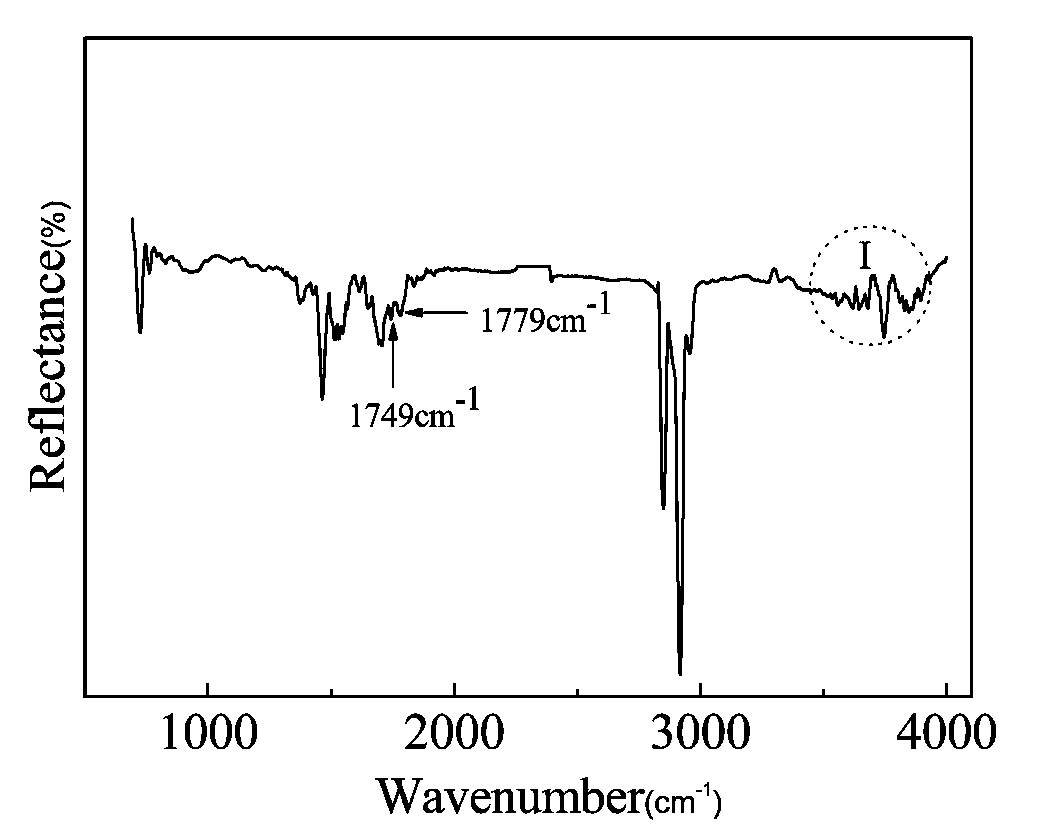

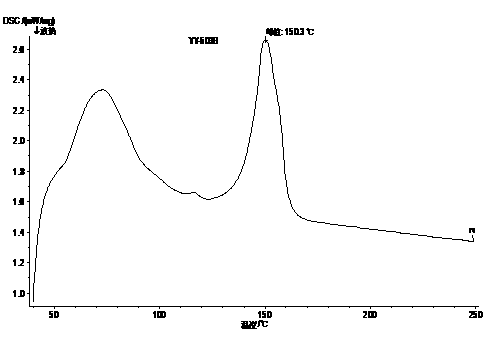

Method used

Image

Examples

Embodiment 1

[0034] Weigh and batch according to the following formula: 85 parts of ABS, 5 parts of silver powder, 2 parts of YY-503 coupling lubrication composite modifier, 5 parts of petroleum resin, 2.8 parts of calcium carbonate, and 0.2 part of antioxidant.

[0035] The above components are pre-mixed evenly with a mixer, and then melted and granulated with a twin-screw extruder with a diameter of 40 mm and a length-to-diameter ratio of 36:1. rpm.

[0036] The prepared metal-like ABS modified material was dried at 80°C for 2 hours, and the mechanical sample strip and standard color plate were injected at 200°C by an injection molding machine, and the length of weld line and mechanical properties were measured.

Embodiment 2

[0038] Weighing and ingredients according to the following formula: 82 parts of ABS, 2 parts of gold powder, 0.2 parts of carbon black, 0.3 parts of phthalocyanine blue, 5 parts of YY-503 coupling lubrication composite modifier, 5 parts of petroleum resin, 3 parts of barium sulfate, 2.3 parts of talcum powder, 0.2 part of antioxidant.

[0039] The above components are pre-mixed evenly with a mixer, and then melted and granulated with a twin-screw extruder with a diameter of 40mm and a length-to-diameter ratio of 36:1. rpm.

[0040] The prepared metal-like ABS modified material was dried at 80°C for 2 hours, and the mechanical sample strip and standard color plate were injected at 200°C by an injection molding machine, and the length of weld line and mechanical properties were measured.

Embodiment 3

[0042] Weighing and batching according to the following formula: 76 parts of ABS, 3 parts of pearlescent pigment, 3 parts of silver powder, 0.8 parts of titanium dioxide, 5 parts of YY-503 coupling lubrication composite modifier, 8 parts of petroleum resin, 3.4 parts of talc powder, anti 0.8 parts of oxygen agent.

[0043] The above components are pre-mixed evenly with a mixer, and then melted and granulated with a twin-screw extruder with a diameter of 40mm and a length-to-diameter ratio of 36:1. rpm.

[0044] The prepared metal-like ABS modified material was dried at 80°C for 2 hours, and the mechanical sample strip and standard color plate were injected at 200°C by an injection molding machine, and the length of weld line and mechanical properties were measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com