Graphene material based disperse and quick solid-phase extraction method

A graphene and extraction technology, applied in material separation, analysis materials, instruments, etc., can solve the problem of low graphene density, and achieve the effect of simple operation, simplified cumbersome operation, and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

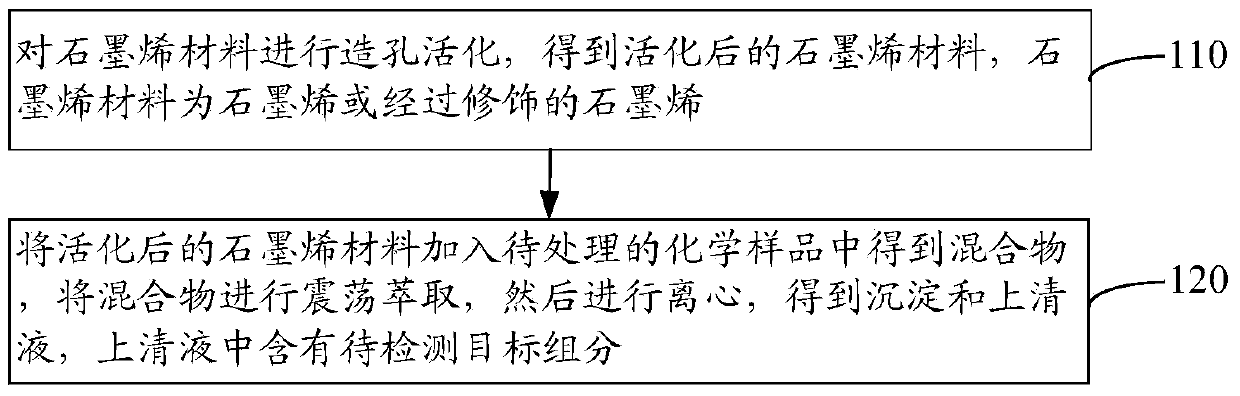

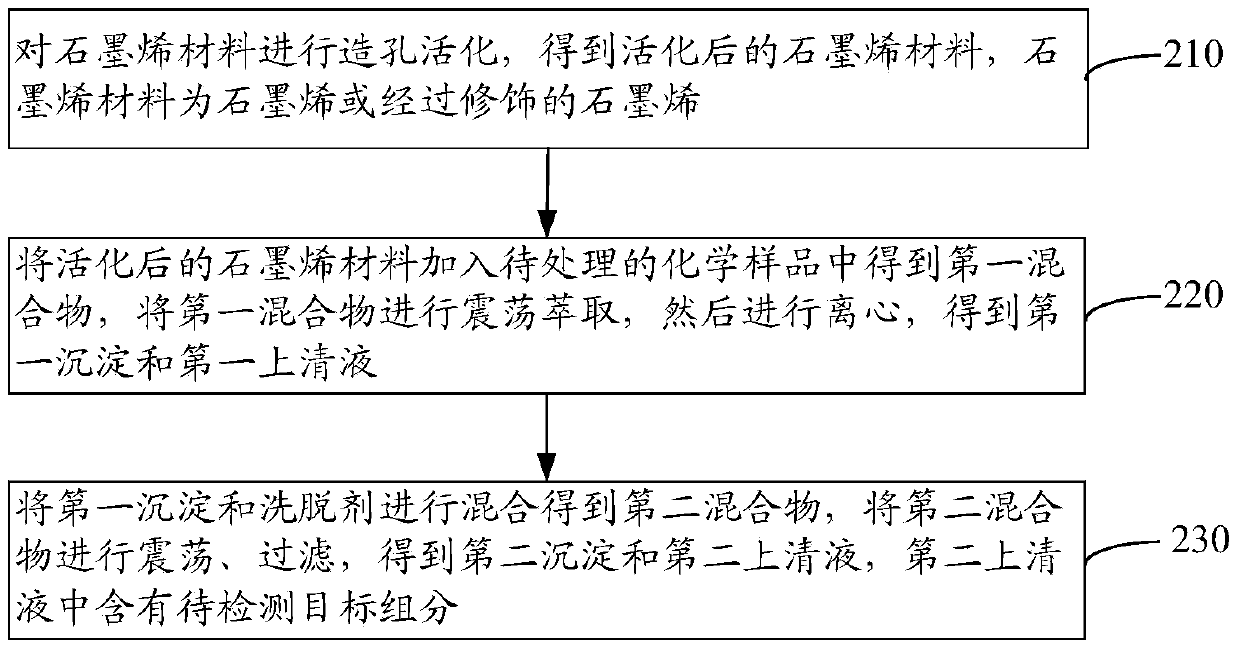

Method used

Image

Examples

Embodiment 1

[0080] 1. Put single-layer graphene into a tube furnace, feed nitrogen, heat to 300°C in a nitrogen atmosphere, stop feeding nitrogen, and feed water vapor into the tube furnace for activation for 3 hours, wherein the flow rate of water vapor It is 5mL / min. Then, stop feeding water vapor, change to nitrogen, stop heating after 5 minutes, take out the graphene material, rinse with deionized water for 3 times, and dry at 60°C for 2 hours to obtain activated single-layer graphene.

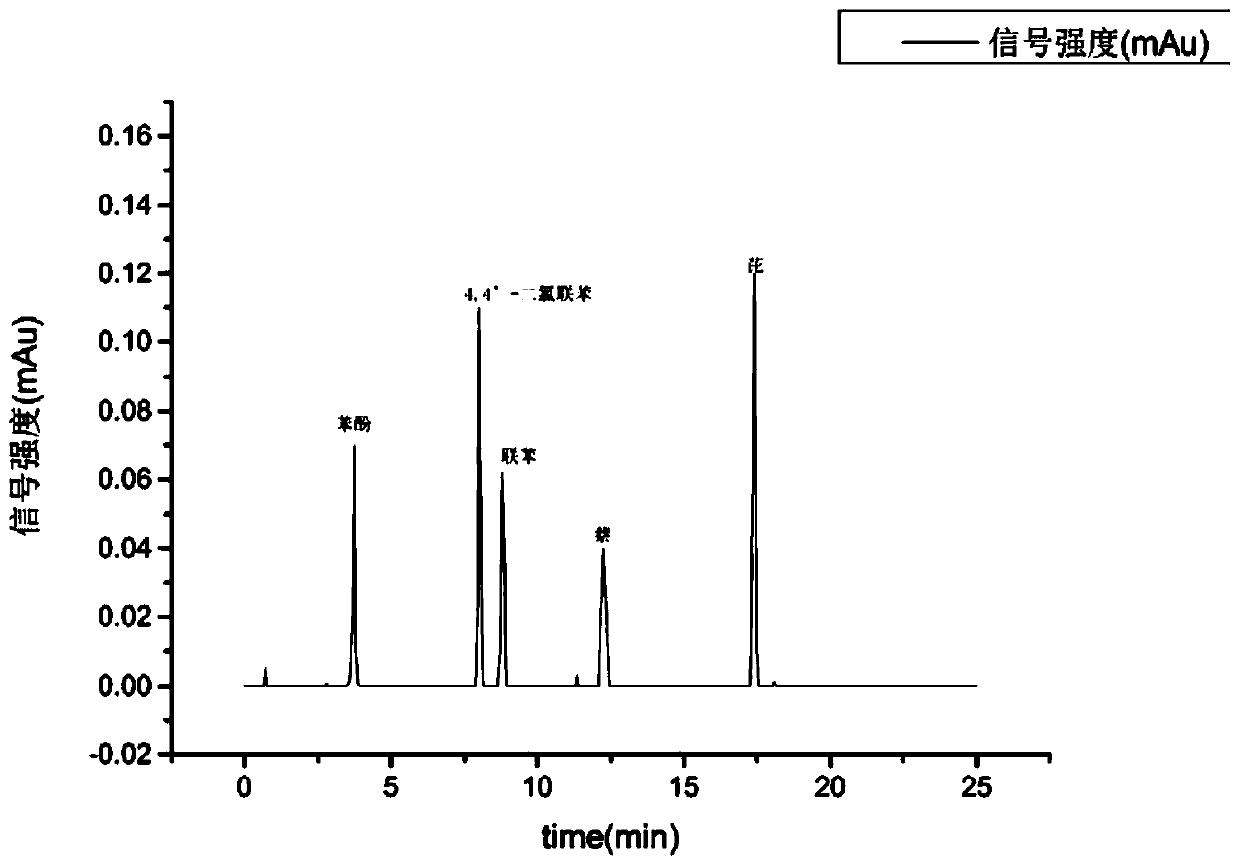

[0081] 2. Mix phenol, 4,4'-dichlorobiphenyl, biphenyl, naphthalene and pyrene to prepare a working solution with the concentration of each component being 100 μg / Kg. The solvent is dichloromethane, and then add porphyrin As an impurity component, the concentration of porphyrin was 1 mg / L.

[0082] 3. Take 5g of the above-mentioned working solution, add the above-mentioned activated single-layer graphene into 5g of the above-mentioned working solution according to the ratio of adding 30mg of solid-pha...

Embodiment 2

[0086] 1. Put the aminated graphene into a tube furnace, feed nitrogen, heat to 500°C in a nitrogen atmosphere, stop feeding nitrogen, and feed water vapor into the tube furnace for activation for 1 hour, wherein the flow rate of water vapor 0.5mL / min. Then, stop feeding water vapor, change to nitrogen gas, stop heating after 1 min, take out the graphene material, rinse with deionized water for 3 times, and dry at 80°C for 1 h to obtain activated aminated graphene.

[0087] 2. Mix phenylalanine, leucine, histidine, and lysine to prepare a working solution with a concentration of 100 μg / L for each component. The solvent is acetonitrile, and methyl violet is added as an impurity group Minutes, the concentration of methyl violet is 1mg / L.

[0088] 3. Take 5g of the above-mentioned working solution, add the above-mentioned activated aminated graphene into 5g of the above-mentioned working solution according to the ratio of adding 5mg of solid phase extractant per gram of each com...

Embodiment 3

[0092] 1. Put carboxylated graphene into a tube furnace, feed nitrogen, heat to 400°C in a nitrogen atmosphere, stop feeding nitrogen, and feed water vapor into the tube furnace for activation for 2 hours, wherein the flow rate of water vapor It is 2mL / min. Then, stop feeding water vapor, change to nitrogen gas, stop heating after 3 minutes, take out the graphene material, rinse with deionized water for 3 times, and dry at 70° C. for 1.5 h to obtain activated carboxylated graphene.

[0093] 2. Grind Coptis Rhizoma with a food grinder and pass it through a 100-mesh sieve to obtain Coptis Rhizoma powder, then take 0.5g of Coptis Rhizoma powder and add it to 200ml of mixed solvent of hydrochloric acid-methanol (the volume ratio of hydrochloric acid and methanol is 1:100), and extract in a water bath at 60°C 2h, and then ultrasonically crush the remaining Coptis rhizome residue. Finally, the residue of Coptidis rhizome was removed by filtration, and the extract solution of Coptid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com