Algae-based gastric pH response disintegrative empty capsule and preparation method thereof

A technology of hollow capsules and disintegration, which is applied in the field of seaweed-based gastric pH-responsive disintegration hollow capsules and its preparation, which can solve the risks of raw material sources and safety, easy to be infected and hydrolyzed by microorganisms, and capsules are volatile Brittle and broken problems, to achieve the effect of promoting reasonable and efficient utilization, not easy to grow microorganisms, and improving over-reliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

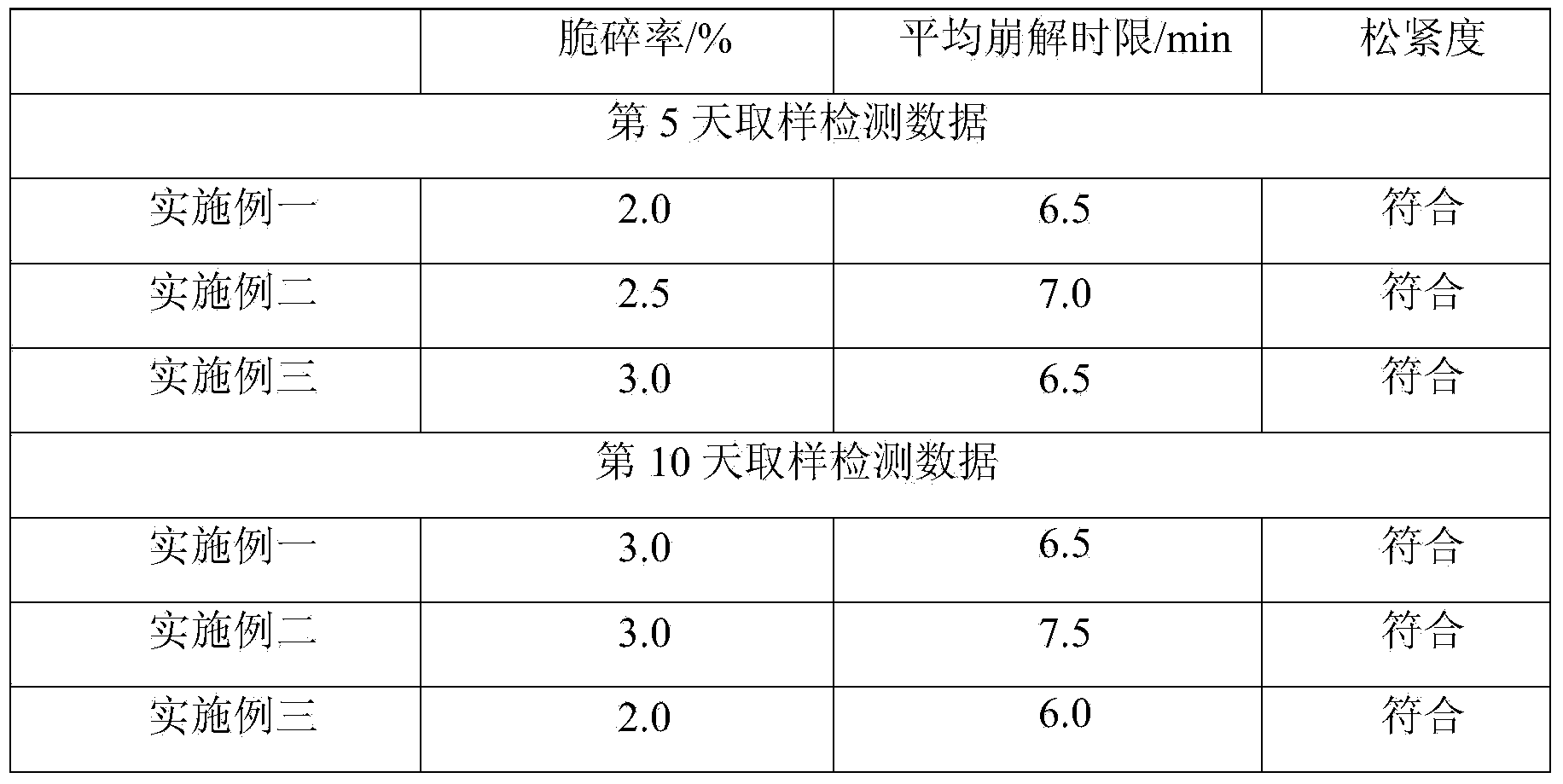

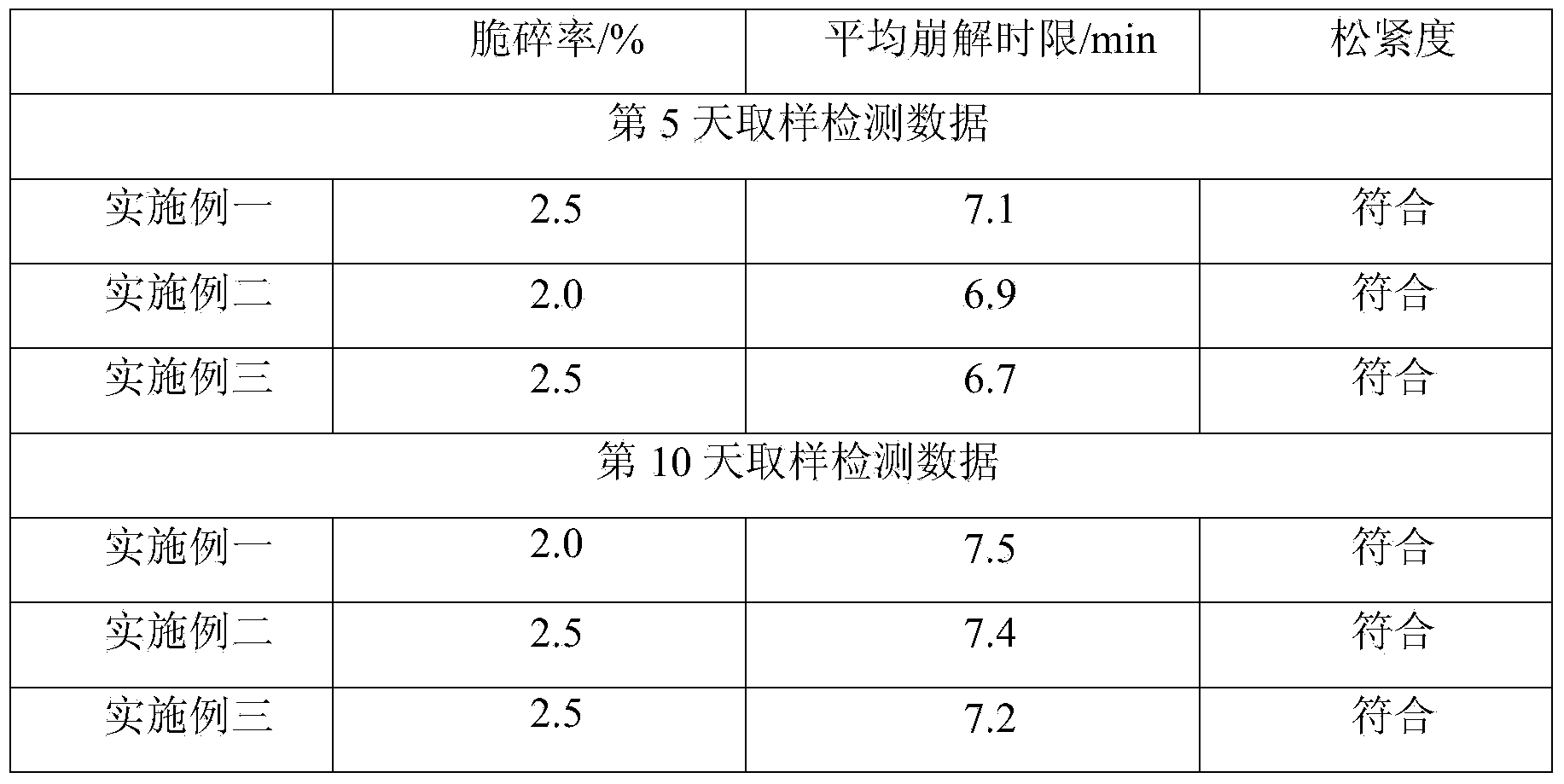

Examples

Embodiment 1

[0021] Embodiment 1: A method for preparing a seaweed polysaccharide-based gastric pH-responsive disintegrating hollow capsule, comprising the following steps:

[0022] 1) Dosing and sol: According to the high G type sodium alginate 11.2% with a viscosity of 5cP (G / M ratio is 1.0), the high M type sodium alginate with a viscosity of 14cP 4% (G / M ratio is 0.60), κ-carrageenan 1.8%, maltodextrin 2%, potassium chloride 0.03%, sodium carboxymethyl starch 0.65%, glycerin 1.5%, sodium lauryl sulfate 0.05%, triethyl citrate 0.3% by weight volume Ratio (w / v) for the ingredients of each raw material, and all raw materials and 100mL deionized water for solution, sol, and sol in a constant temperature water bath at 80 ° C, stirring during the sol process to make the raw materials absorb water and swell and dissolve, sol Properly stir for 1.5hr during the process;

[0023] 2) Degassing the gelatin: After the sol is completed, put the gelatin in a constant temperature water bath at 50°C t...

Embodiment 2

[0026] The preparation method of the seaweed polysaccharide-based stomach pH-responsive disintegrating hollow capsule of Example 2 comprises the following steps:

[0027] 1) Liquid preparation and sol: according to the viscosity of 7cP high G type sodium alginate 9.5% (G / M ratio is 1.0), the viscosity of 10cP high M type sodium alginate 5.5% (G / M ratio is 0.60), Low acyl gellan gum 0.5%, maltodextrin 1.5%, potassium chloride 0.02%, crospovidone 0.5%, glycerin 1%, water-soluble silicone oil 0.2% weight-volume ratio (w / v) carries out each raw material Batching, and all raw materials and 100mL deionized water for solution, sol. First, dissolve low-acyl gellan gum in 100mL deionized water at 95°C to form a transparent solution, then lower the temperature of the solution to 80°C, then add the rest of the ingredients, stir to make the raw materials absorb water and swell and dissolve, and stir for 1.0hr during the sol process ;

[0028] 2) Degassing the gelatin: After the sol is c...

Embodiment 3

[0031] The preparation method of the seaweed polysaccharide-based stomach pH-responsive disintegrating hollow capsule of Example 3 comprises the following steps:

[0032] 1) Dosing and sol: according to the viscosity of 9cP high-G sodium alginate 8.8% (G / M ratio is 1.0), the viscosity of 7cP high-M sodium alginate 5.2% (G / M ratio is 0.60), κ-carrageenan 2.0%, potassium chloride 0.05%, glycerin 0.3%, PEG 0.2%, crospovidone 0.25%, carboxymethyl starch sodium 0.25%, sodium lauryl sulfate 0.03% weight-volume ratio (w / v) Do the batching of each raw material, mix all the raw materials with 100mL deionized water, sol, and sol in a constant temperature water bath at 75°C, stir during the sol process to make the raw materials absorb water and swell and dissolve, the sol process Properly stir in medium for 0.5hr;

[0033] 2) Degassing of gelatinization: After the sol is completed, put the gelatinization in a constant temperature water bath at 60°C to degas for 6 hours, and set aside; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com