Silver nanowire and M-phase vanadium dioxide nanoparticle composite film and preparation method thereof

A vanadium dioxide nanometer and silver nanowire technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of poor phase conductivity, expensive equipment, harsh process conditions, etc., and achieve an increase in the magnitude of resistance mutation. , The effect of infrared light regulation range improvement and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concrete steps of preparation are:

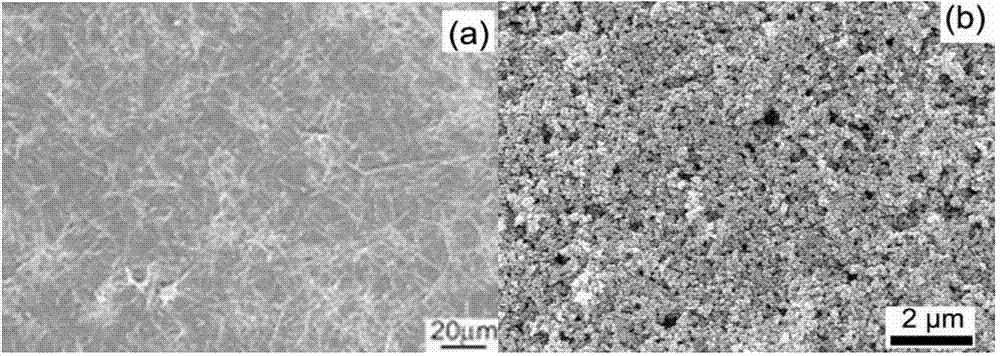

[0041] In step 1, silver nanowires with a wire diameter of 40 nm and a wire length of 50 μm are dispersed in isopropanol to obtain a silver nanowire solution with a concentration of 0.3 wt % in isopropanol. Then the silver nanowire isopropanol solution is spin-coated (or scraped) on the substrate; wherein, the substrate is a polyethylene terephthalate substrate, and after drying, a figure 1 a shows the substrate covered with silver nanowire film.

[0042] Step 2, spin coating (or scrape coating) an organic conductive polymer material on the silver nanowire film of the substrate coated with the silver nanowire film; wherein, the organic conductive polymer material is polyaniline. Afterwards, the M-phase vanadium dioxide nanoparticles with a particle diameter of 20nm are dispersed in water (or ethanol) to obtain a concentration of 2wt% M-phase vanadium dioxide nanoparticles aqueous solution (or M-phase vanadium dioxide nanoparticl...

Embodiment 2

[0044] The concrete steps of preparation are:

[0045] In step 1, silver nanowires with a wire diameter of 55 nm and a wire length of 63 μm were dispersed in isopropanol to obtain a silver nanowire isopropanol solution with a concentration of 0.6 wt%. Then the silver nanowire isopropanol solution is spin-coated (or scraped) on the substrate; wherein, the substrate is a polyethylene terephthalate substrate, and after drying, a figure 1 a shows the substrate covered with silver nanowire film.

[0046] Step 2, spin coating (or scrape coating) an organic conductive polymer material on the silver nanowire film of the substrate coated with the silver nanowire film; wherein, the organic conductive polymer material is polyaniline. Afterwards, the M phase vanadium dioxide nanoparticles with a particle diameter of 40nm are dispersed in water (or ethanol) to obtain a concentration of 3wt% M phase vanadium dioxide nanoparticles aqueous solution (or M phase vanadium dioxide nanoparticles ...

Embodiment 3

[0048] The concrete steps of preparation are:

[0049] In step 1, silver nanowires with a wire diameter of 70 nm and a wire length of 75 μm were dispersed in isopropanol to obtain a silver nanowire solution with a concentration of 0.9 wt % in isopropanol. Then the silver nanowire isopropanol solution is spin-coated (or scraped) on the substrate; wherein, the substrate is a polyethylene terephthalate substrate, and after drying, the following figure 1 a shows the substrate covered with silver nanowire film.

[0050] Step 2, spin coating (or scrape coating) an organic conductive polymer material on the silver nanowire film of the substrate coated with the silver nanowire film; wherein, the organic conductive polymer material is polyaniline. Afterwards, the M-phase vanadium dioxide nanoparticles with a particle diameter of 60nm are dispersed in water (or ethanol) to obtain a concentration of 3.5wt% M-phase vanadium dioxide nanoparticles aqueous solution (or M-phase vanadium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com