Purifying method for copper chelate of pingyangmycin and same-family compounds thereof

A technology of pingyangmycin and copper chelate, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of inability to achieve rapid separation, low purity of the final product, and low separation degree, etc. Achieve the effect of improving the quality of the final product, good rigidity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

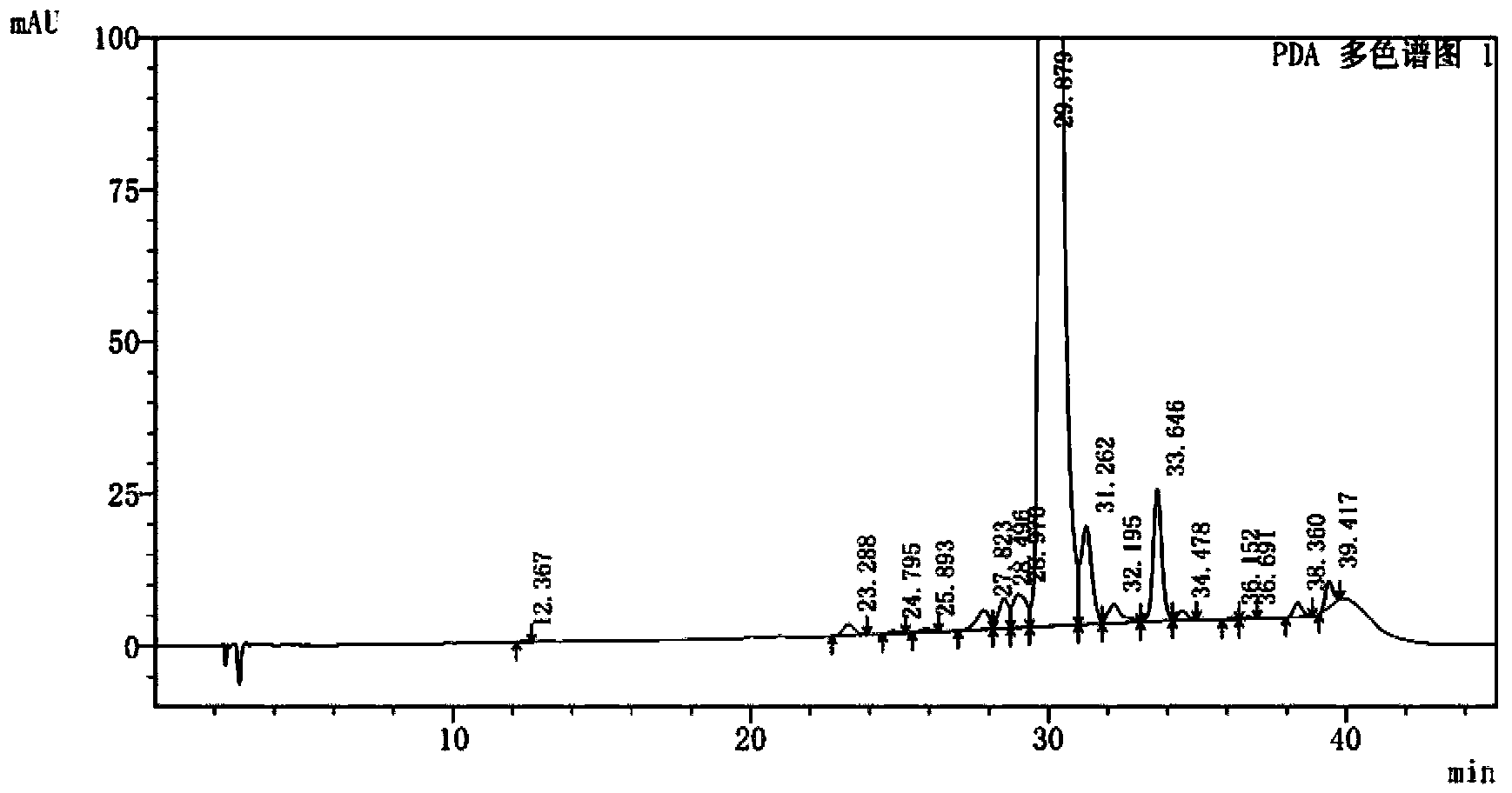

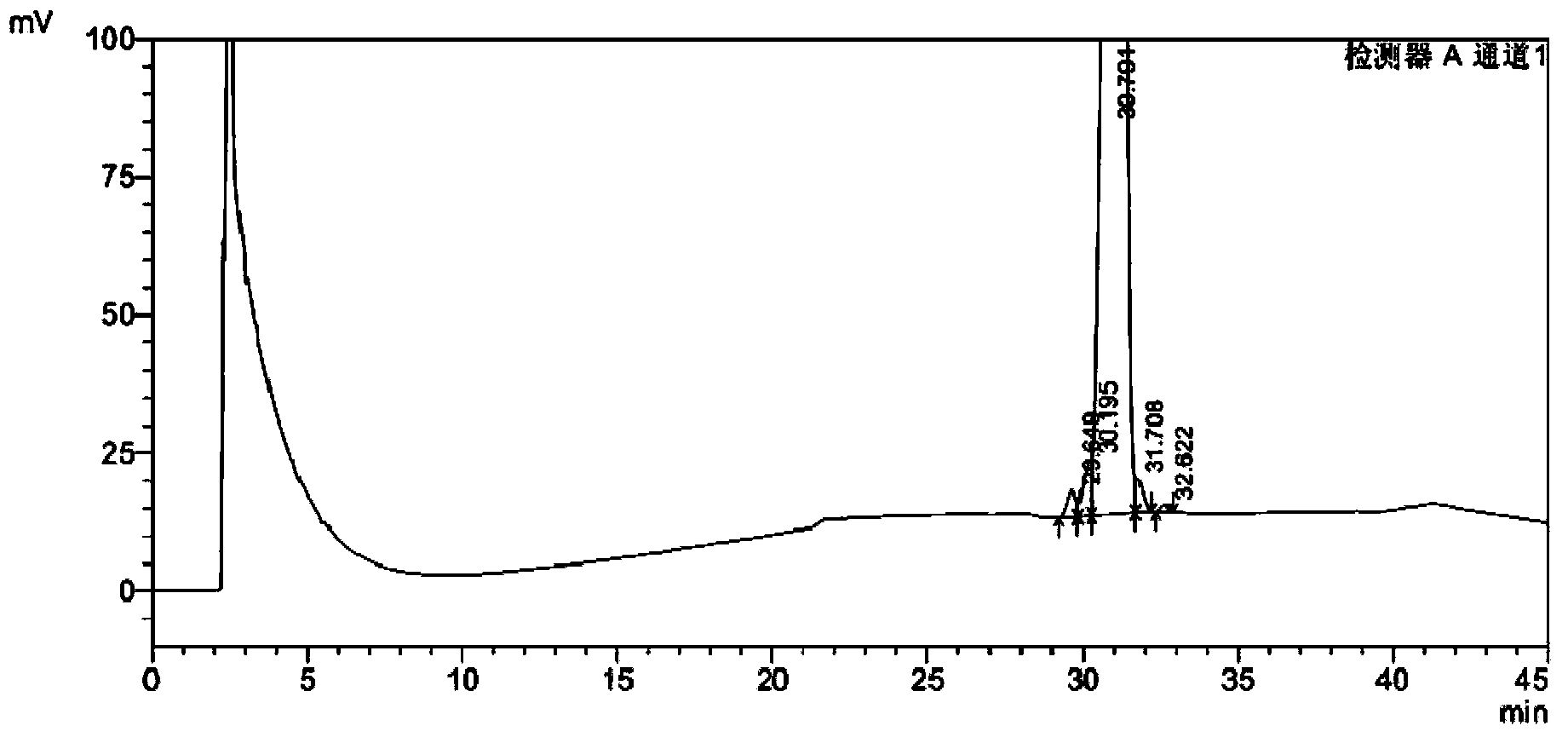

[0034] Take 3.0 grams of Pingyangmycin copper chelate crude product (content 55%), dissolve it with ultrapure water, and go up to the UniPS equilibrated with ultrapure water in advance TM -30 Chromatographic column with a series of fillers, the diameter of the filler is 2.5cm, and the height is 40cm. Chromatography flow rate 0.8ml / (min cm 2 ). Use ethanol-water system to elute with 0%-15% linear gradient for 4 column volumes (here refers to the volume of the filler, the same below), then wash 1 column volume with 15% ethanol, and finally wash the column with 30% ethanol All the ribbons on the top are all down. The single chromatography time is about 4.5 hours, and the fractions with a purity of more than 85% are collected, concentrated to dryness under reduced pressure, and the purity and recovery are measured. The purity is 87.6%, and the recovery rate is 82%. The samples were reuploaded to a UniPS equilibrated with ultrapure water TM -30 The chromatographic column w...

Embodiment 2

[0036] Take 10 grams of Pingyangmycin copper chelate crude product (content 48%), dissolve with ultrapure water, and go up to the UniPS that is equilibrated with ultrapure water in advance TM -40 Chromatographic column with a series of fillers, the diameter of the filler is 2.5cm, and the height is 40cm. Chromatography flow rate 0.8ml / (min cm 2 ). Use methanol-water system to elute 4 column volumes according to a linear gradient of 0%-15%, then wash 1 column volume with 15% methanol, and finally use 50% methanol to remove all the color bands on the column. The single chromatography time is about 4.5 hours, and the fractions with a purity of more than 85% are collected, concentrated to dryness under reduced pressure, and the purity and recovery are measured. The purity is 86.1%, and the recovery rate is 76%. The samples were reuploaded to a UniPS equilibrated with ultrapure water TM -40 The chromatographic column with a series of fillers was operated the same as above t...

Embodiment 3

[0038] Get 40 grams of pingyangmycin copper chelate crude product (content 56%), dissolve with ultrapure water, and go up to equilibrate UniPS with 10% methanol in advance TM -40 Chromatographic column with a series of fillers, the diameter of the filler is 5.0cm, and the height is 150cm. Chromatography flow rate 1.8ml / (min cm 2 ). Elute isocratically with 10% aqueous methanol for a total of 4 column volumes, and finally wash the column with 50% methanol. The single chromatography time was 6 hours, and the fractions with a purity of more than 85% were collected, concentrated to dryness under reduced pressure, and the purity and recovery were measured. The purity is 89.3%, and the recovery rate is 84%. Reload the sample to a UniPS equilibrated with 10% methanol TM -40 The chromatographic column with a series of fillers is the same as the above operation, and the fractions with a purity of more than 97% are collected, combined, concentrated under reduced pressure and eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com