Liquid silicon resin and preparation method and application thereof

A liquid silicon and resin technology, applied in the direction of adhesive additives, polymer adhesive additives, etc., can solve the problems of high risk, volatile transportation, difficulties, etc., to reduce the generation of waste acid, wide economic value, high The effect of market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

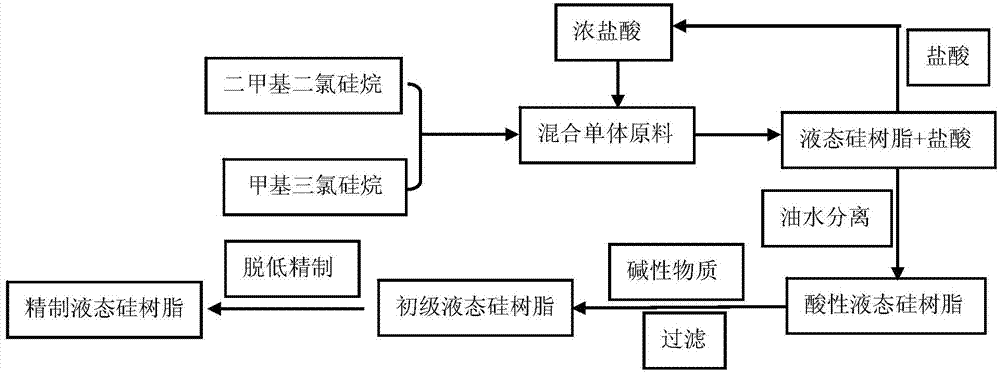

[0026] Such as figure 1 Shown, the preparation method of liquid silicone resin of the present invention, the reactor that adopts has stirring and condensation reflux device, comprises the following steps:

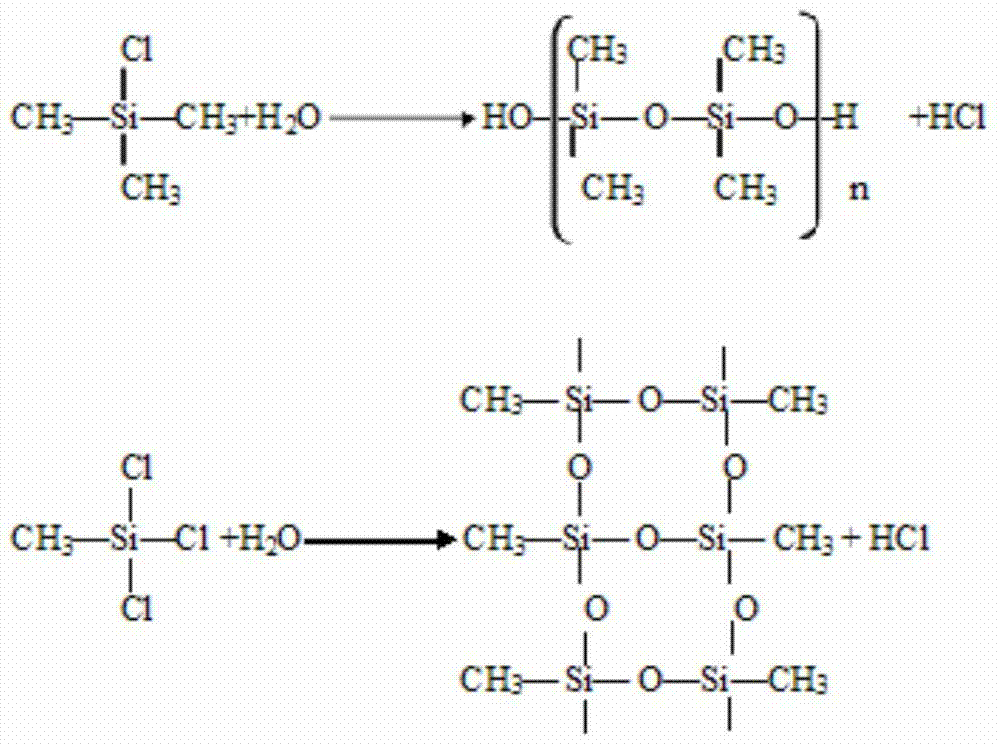

[0027] a. Raw material preparation: Methyltrichlorosilane and dimethyldichlorosilane are mixed at a mass ratio of 63:7-27 to obtain a mixed monomer. And reduce the temperature of the reactor to below 5°C. Cooling can use low-temperature circulation tank to cool the raw materials.

[0028] b. Dropping reaction: Add concentrated hydrochloric acid dropwise to the reaction kettle, and control the temperature of the reaction system not to exceed -10-5°C. After the concentrated hydrochloric acid was added dropwise, the reaction was performed until no bubbles were generated, and the reaction system was separated from oil and water.

[0029] The concentration of concentrated hydrochloric acid is preferably 33 to 37%. The dropping speed of concentrated hydrochloric acid can be p...

Embodiment 1

[0041] The mass ratio of dimethyldichlorosilane to methyltrichlorosilane is 9:1; the hydrolysis temperature is 0°C; it is neutralized with sodium carbonate, the dehydration temperature is 140°C, and the pressure is -0.06MPa.

[0042] Add 500 volumes of mixed monomer raw materials into the reaction kettle, cool down to 0° C., and add 200 volumes of concentrated hydrochloric acid dropwise while stirring. After 2 hours, the dropwise addition was completed, and no bubbles were produced after standing for 0.5 hours, and the layers were separated, and the hydrochloric acid at the bottom of the reaction kettle was released, and the concentration of the separated hydrochloric acid was 35%. Add solid sodium carbonate to the oil layer to neutralize to neutral, filter the filtrate and carry out rotary distillation for 3 hours, control the dehydration temperature to 140°C and pressure -0.06MPa to obtain the product. Viscosity is 86mm 2 / s, the refractive index is 1.39, and the volatile m...

Embodiment 2

[0045] The mass ratio of dimethyldichlorosilane to methyltrichlorosilane is 4:1; the hydrolysis temperature is -5°C; it is neutralized with sodium bicarbonate, the delowering temperature is 130°C, and the pressure is -0.09MPa.

[0046] Add 500 volumes of mixed monomer raw materials into the reactor, cool down to -5°C, and add 200 volumes of concentrated hydrochloric acid dropwise while stirring. After 2 hours, the dropwise addition was completed, and no bubbles were produced after standing for 0.5 hours, and the layers were separated, and the hydrochloric acid at the bottom of the reaction kettle was released, and the concentration of the separated hydrochloric acid was 33%. Add solid sodium bicarbonate to the oil layer to neutralize until neutral, filter the filtrate and carry out rotary distillation for 3 hours, control the dehydration temperature to 130°C and pressure -0.09MPa to obtain the product. Viscosity is 115mm 2 / s, the refractive index is 1.41, and the volatile ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com