Oxidized graphene and trivalent chromium composited tanning agent and preparation method thereof

A technology of graphene and trivalent chromium, which is applied in chemical treatment of small raw hide/big raw hide/leather skin/fur, small raw hide/big raw hide/leather/fur treatment, tanning treatment, etc. It can solve the problem of limited effect and chromium content Sludge, a large amount of chromium-containing wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

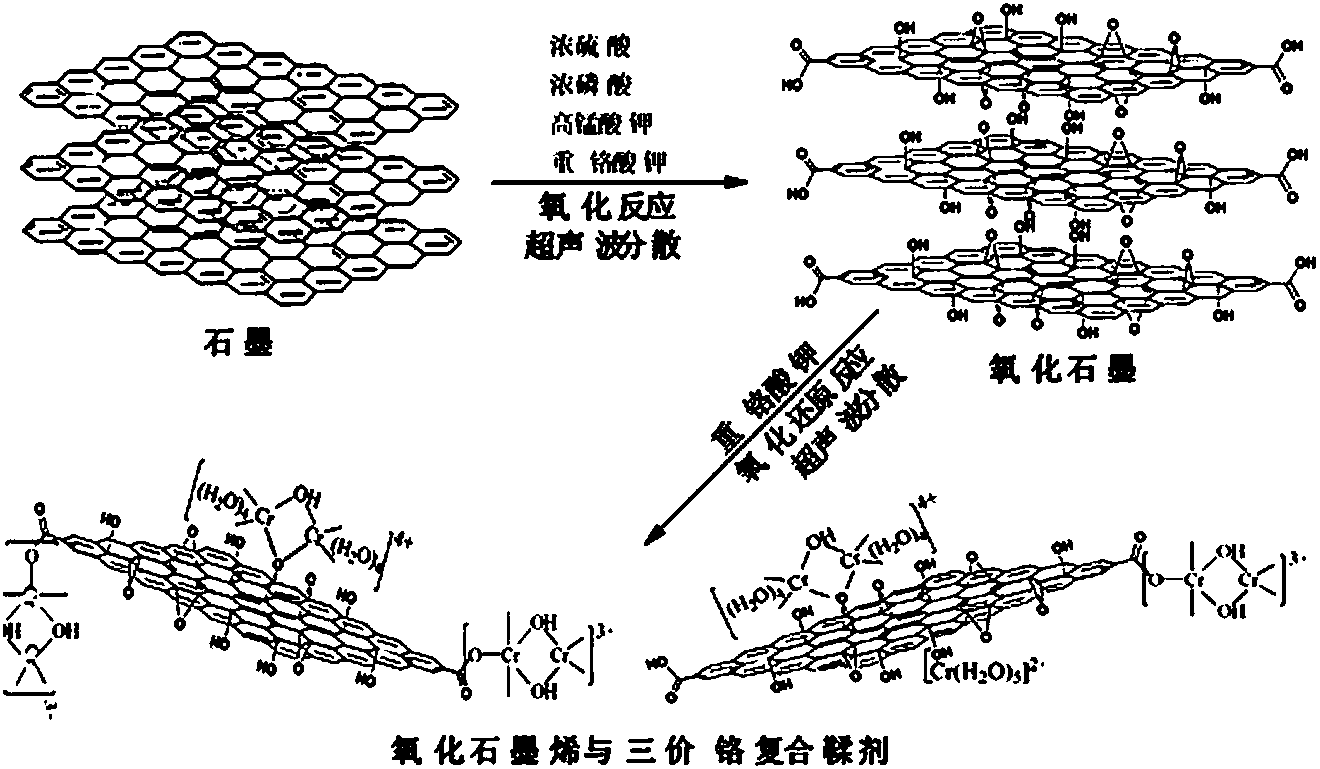

[0021] The preparation method of described graphene oxide nano flake dispersion liquid is: 2 parts of graphite powders are slowly added to 50 parts of mass fractions and are the mixture of 98% concentrated sulfuric acid and 3 parts of mass fractions of 85% concentrated phosphoric acid, and the control system The temperature is 5°C, after stirring evenly, slowly add 3 parts of potassium permanganate and 3 parts of potassium dichromate mixture to react for 3 hours, then raise the temperature to 30°C and continue the reaction for 2 hours, then slowly add 80 parts of deionized water, heat up React at 90°C for 1 hour; then cool down to 30°C and add 20 parts of hydrogen peroxide solution with a mass fraction of 30% dropwise, react for 50 minutes, prepare graphene oxide nanosheet dispersion liquid by ultrasonic dispersion for about 1 hour, and detect graphite oxide The size of the ene nanosheets is in the range of 4 to 20nm, and the oxygen content of graphene oxide is in the range of ...

Embodiment 1

[0027] Step 1: Preparation of graphene oxide.

[0028] Slowly add 2 parts of graphite powder to a mixture of 50 parts of concentrated sulfuric acid with a mass fraction of 98% and 3 parts of concentrated phosphoric acid with a mass fraction of 85%, control the temperature of the system at 5°C, stir well and slowly add 3 parts of high manganese Potassium dichromate and 3 parts of potassium dichromate mixture were reacted for 3 hours, then heated up to 30°C and continued to react for 2 hours, then slowly added 80 parts of deionized water, heated to 90°C and reacted for 1 hour; then cooled to 30°C and added dropwise 20 A hydrogen peroxide solution with a mass fraction of 30% was reacted for 50 minutes, and the graphene oxide nanosheet dispersion was prepared by ultrasonic dispersion for about 1 hour. The size of the graphene oxide nanosheets was detected to be in the range of 4-20nm. The oxygen content is in the range of 29%~35%.

[0029] Step 2: Preparation of stable dispersant...

Embodiment 2

[0034] Step 1: Preparation of graphene oxide.

[0035] Slowly add 2 parts of graphite powder to a mixture of 50 parts of concentrated sulfuric acid with a mass fraction of 98% and 3 parts of concentrated phosphoric acid with a mass fraction of 85%, control the temperature of the system at 5°C, stir well and slowly add 3 parts of high manganese Potassium dichromate and 3 parts of potassium dichromate mixture were reacted for 3 hours, then heated up to 30°C and continued to react for 2 hours, then slowly added 80 parts of deionized water, heated to 90°C and reacted for 1 hour; then cooled to 30°C and added dropwise 20 A hydrogen peroxide solution with a mass fraction of 30% was reacted for 50 minutes, and the graphene oxide nanosheet dispersion was prepared by ultrasonic dispersion for about 1 hour. The size of the graphene oxide nanosheets was detected to be in the range of 4-20nm. The oxygen content is in the range of 29%~35%.

[0036] Step 2: Preparation of stable dispersant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com